Plastics Use in the Automotive Industry

Plastics in automotive enable lightweighting via numerous applications including under-the-hood, instrument panels, gas tanks, fuel lines, lenses, bumpers, display screens, gears, and housings.

ESSENTIAL READING

VIEW ALLProtolabs Addresses How to Survive a Pandemic with Digital Manufacturing

Protolabs survey results examine product development and the supply chain.

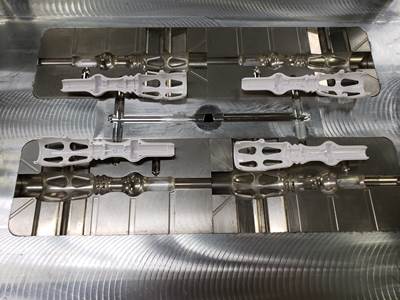

Read MoreHow to Properly Maintain Aluminum Injection Molds

Aluminum and steel tools have some important differences, but also one key similarity: Routine maintenance will extend the mold’s life and boost the quality of its output.

Read MoreHow to Manage Pressure Loss in Injection Molding

Achieving a process window wide enough to ensure consistent part quality depends on achieving sufficient pressure at end of fill.

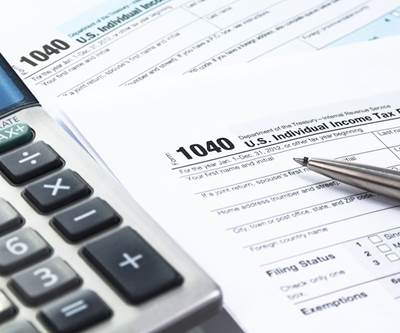

Read MoreWhat Plastics Processors Need to Know about Tax Reform and Equipment Acquisition

The Tax Cuts and Jobs Act of 2018 (TCJA) is positioning plastics processors for more growth and profitability following the most recent Plastics Processing Index showing the best quarter since 2013 when the index began.

Read MoreWhat Blow Molders Say About All-Electric Machines

They are well established in Europe, but molders in North America are just beginning to come around to all-electrics’ improved performance, maintenance, cleanliness, and—yes— energy efficiency. Here’s first-hand testimony, from the U.S. and abroad.

Read MoreWhat’s the True Cost of Buying A ‘Low-Cost’ Mold Overseas?

The head of a Canadian moldmaking company exposes the limitations of focusing solely on initial purchase cost when considering mold sourcing in China.

Read MoreLatest Automotive News And Updates

Matting Agent Designed for Engineering Resin Automotive and Other Types of Components

CAI Performance Additives’ ST-B50T is effective in ABS, PC/ABS, PC/ASA and PC/PBT.

Read MoreRecycled Plastic Applied In Composite Railroad Ties

Granite Peak Plastics announced the launch of Triton Ties, an alternative to wooden ties.

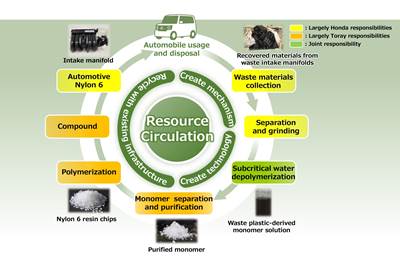

Read MoreChemical Recycling Trials for Glass-Reinforced Nylon

Honda and Toray are jointly validating a process for recycling Nylon 6 with automotive applications.

Read MoreBiobased Mold Release for PP Automotive Formulations

Palsgaard’s Einar 201 was developed to help automotive compounders enhance the sustainability of PP formulations for class ‘A’ mold release.

Read MoreUltralight Cargo Bikes Leverage 3D Printed Parts

Carbon fiber bicycle maker Maniac & Sane developed a lightweight carbon fiber cargo bike with 3D printed components using Evonik’s Infinam PA12.

Read MoreThermoplastic Elastomers With Recycled Content for Automotive Applications

Avient announced new grades of TPE to meet demand for recycled content.

Read MoreFeatured Posts

Additive Fusion Technology Optimizes Composite Structures for Demanding Applications

9T Labs continues to enhance the efficiency of its technology, which produces composite parts with intentionally oriented fibers.

Read MoreMolder Repairs Platen Holes with Threaded Inserts

Automotive molder ITW Deltar Fasteners found new life for the battered bolt holes on its machine platens with a solution that’s designed to last.

Read MoreAtop the Plastics Pyramid

Allegheny Performance Plastics specializes in molding parts from high-temperature resins for demanding applications as part of its mission to take on jobs ‘no one else does.’

Read MoreDesign Optimization Software Finds Weight-Saving Solutions Outside the Traditional Realm

Resin supplier Celanese turned to startup Rafinex and its Möbius software to optimize the design for an engine bracket, ultimately reducing weight by 25% while maintaining mechanical performance and function.

Read MoreHonda Now Exploring UBQ’s Biobased Material Made from Unsorted Household Waste

UBQ is aiming to expand its reach for more sustainable automotive parts as well as non-automotive applications.

Read MoreNew CRM Streamlines Quoting for Automotive Molder

Eliminating the need to contact each supplier for every individual quote, a new CRM for automotive supplier Axiom Group tracks past quotes as well as industry history to generate fast, reliable RFQs and more.

Read More

.png;maxWidth=300;quality=90)