Injection Molding

Automated Injection Molding Process Adjustments

Shibaura says its S-Concept represents an AI technology capable of making real-time process adjustments.

Read MoreEnhanced Temperature Controls for Hot Runners, Extrusion and Packaging

NPE2024: Athena introduces expanded hot-runner controller with up to 120 zones, plus updated panel-mount “universal” temperature/process control.

Read MoreNext-Generation All-Electric and Vertical Injection Molding Machines

Sodick Plustech’s VR-G and MS-G2 Series both utilize the company’s proprietary V-Line technology, separating plasticizing and injection functions, and have upgraded displays, energy efficiency, response time and more.

Read More3D Printed Hot Runner Nozzles, Pressure Pads Provide Reliable Temperature Handling

NPE2024: Witosa GmbH, through its distributor DMS, brings the Monolith hot runner nozzle and hardened steel Energy Blocker to the U.S., enabling the reduction in time, costs and improvements in product quality.

Read MoreAbsolute Haitian Brings Next Generation of Presses to Orlando

NPE2024: Absolute Haitian says Generation 5 of the servo-hydraulic Haitian and electric Zhafir machines lines emphasize efficiency, performance and intelligence.

Read MoreProcessing Megatrends Drive New Product Developments at NPE2024

It’s all about sustainability and the circular economy, and it will be on display in Orlando across all the major processes. But there will be plenty to see in automation, AI and machine learning as well.

Read More'Simple' Units Feature State-of-the-Art Controls

NPE2024: New dryer line from Motan billed as the most cost-effective entry-level models it offers and comes equipped with state-of-the-art control technology.

Read More420 Stainless Steel Now Qualified With TrueShape 3D Printing Technology

NPE2024: Mantle's additive manufacturing technology is designed for precision tooling.

Read MoreEnhanced Dry-Ice Cleaning Systems for Screws, Tooling

NPE2024: Cold Jet will be displaying four new dry-ice cleaning solutions for screw and tooling, and will also offer booth visitors a chance to win one of them.

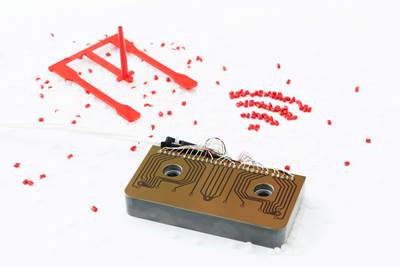

Read MoreThin-Film Sensors Integrated Directly Onto Cavity Surface

Fraunhofer IST researchers say the wear-resistant thin-film sensors are deposited onto the tool surface, enabling direct temperature and flow measurements in critical areas of a mold.

Read More