Postprocessing

Post-processing and secondary operations are key to boosting value added functions for plastics processors. Learn new technologies and best practices for assembly, decoration, packaging, labeling, in-mold labeling, printing, ultrasonic welding, laser welding, vibration welding and more.

ESSENTIAL READING

VIEW ALLA Guide to Ultrasonic Welding Controls

Ultrasonic welding today is a sophisticated process that offers numerous features for precise control. Choosing from among all these options can be daunting; but this guide will help you make sense of your control features so you can approach your next welding project with the confidence of getting good results.

Read MoreHow to Solve Common Ultrasonic Welding Problems

Understand and address the likely origins of welding problems to keep production on track.

Read MoreUnderstanding the Effects of Paint On Plastics

Paint can have significant effects on mechanical properties of plastic parts. As illustrated by this OEM’s procedure in developing new-generation outboard-motor covers, there’s no substitute for thorough testing.

Read MoreHow to Select a Plastics Assembly Process

To make the proper choice, each application must be considered on its own. Each has its own particular characteristics and requirements.

Read MoreHow to Keep Your Conveyor Running Smoothly

Low-profile conveyors are ubiquitous in industry, typically used in 24/7 applications in packaging, assembly, labeling, inspection, and sorting. Here's how to keep them up and running.

Read MoreWhy & How to Assemble Parts While They’re Still Warm

For any molder seeking to maximize productivity and efficiency, carefully managing inventory and warehouse space is a key concern. One way to address this challenge is to assemble parts directly out of the mold, when they’re still warm.

Read MoreLatest Postprocessing News And Updates

Press-Side TCUs and Full-Plant Adiabatic Coolers

NPE2024: Frigel North America will launch RSY Syncro and RS/MD series, as well as new innovations in at-the-press and whole plant cooling.

Read MoreHeated Nippers Offer Easier Degating

Globeius is now offering heavy-duty heated nippers from MouldPro for safer, more efficient cutting of plastics and removal of gates from molded parts.

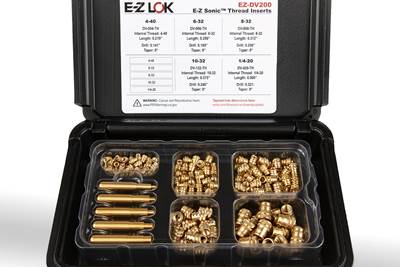

Read MoreUltrasonic Inserts and Heat Staking Kits for Thermoplastics

Made from brass with inch or metric threads, the E-Z Sonic inserts in E-Z Lok’s threaded insert assortment kits can be installed via ultrasonic horn or heat driver.

Read More‘Contactless’ Accumulator Is Gentle to Superthin PET Bottles

Sidel’s Gebo AQFlex protects ultralight PET water bottles from dents at Suntory Japan.

Read MoreUltrashort Pulse Laser Marking System for Medical Devices and More

FOBA’s F.0100-ir creates deep black markings on medical plastics, stainless steel and titanium.

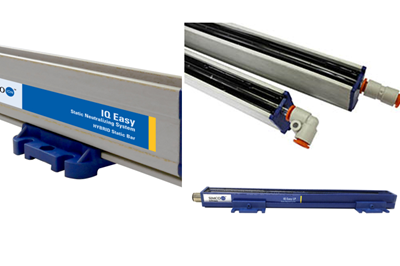

Read MoreDiverse 24V Line-Up of Static Ionizing Bars

Simco’s IQ Easy portfolio includes three 24V static neutralizing bars designed with M12 connectors that allow for power to the pins and more.

Read MoreFeatured Posts

Ultrasonic Welding: Tips, Techniques, and Troubleshooting

In this collection of content, we provide expert advice on welding from some of the leading authorities in the field, with tips on such matters as controls, as well as insights on how to solve common problems in welding.

Read MoreX-Ray Vision Inside Parts Gets More Affordable for Processors

Shimadzu’s new benchtop x-ray CT scanner provides internal and external metrology and flaw detection at a fraction of the previous cost.

Read MoreA Guide to Ultrasonic Welding Controls

Ultrasonic welding today is a sophisticated process that offers numerous features for precise control. Choosing from among all these options can be daunting; but this guide will help you make sense of your control features so you can approach your next welding project with the confidence of getting good results.

Read MoreCan Plastic Recyclates be Welded Ultrasonically?

What is possible with ultrasound? Will the result with recycled plastics material actually be worse than with standard material? Do we have to adapt our technology?

Read MoreSolvent-Based Inks Boost PET Recycling

Sun Chemical’s SunSpectro SolvaWash solvent-based inks allow higher quality and yield of recycled PET from bottles.

Read MoreHow Plasma Treatment Adds Value to Plastics Parts

Think of it as today’s modern form of alchemy, with applications in printing on plastics and bonding plastics to dissimilar materials.

Read MoreFAQ: Postprocessing

In ultrasonic welding, high-frequency vibrations are applied to the surfaces of two parts by a vibrating tool, commonly called a “horn” or “sonotrode.” Welding occurs as the result of frictional heat generated at the interface between the parts. The ultrasonic vibrations are created by a series of components—the power supply, converter, booster, and horn—that deliver mechanical vibration to the parts.

Further Reading About Ultrasonic Welding:

A Step-by-Step Guide to Ultrasonic Welding

How to Solve Common Ultrasonic Welding Problems

Can Plasma Treatment be Used in Plastics?

In plastics, the most common plasma application is improving the bonding power of chemical adhesives; this can involve bonding metal to plastic, silicone to glass, polymers to other polymers, biological content to polymeric microtiter plates, and even bonding to fluoropolymers like PTFE.

Paint can have significant effects on mechanical properties of plastic parts. First, paint solvents may attack the plastic. In fact, it is often desirable for the paint solvents to attack (etch) the plastic to a certain extent, since this improves adhesion. However, solvents can also cause surface crazing, or even environmental stress cracking. In addition, paint solvents may cause swelling, softening, or dissolution of the polymer. Once again, a certain amount of this may help to promote adhesion, but taken to an extreme, it can degrade the properties of the plastic to unacceptable levels.

Postprocessing Supplier Categories

- Labeling Equipment--In-Mold

- Clamps, Holding Devices

- UV Curing Equipment

- UV-resistant Coatings

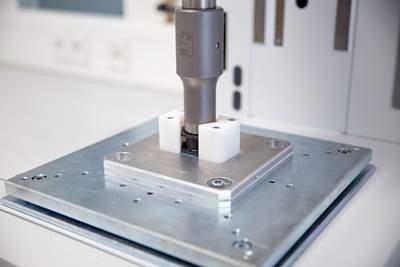

- Machining, Drilling, Routing Equipment

- Plating Equipment for Plastics

- Labels (In-Mold, Out-of-Mold)

- In-mold Decorating Films

- Extrusion Welding

- Product & Tool Design, Analysis Software (CAD/CAM/CAE)

- Labeling Equipment--Out-of-Mold

- Adhesives for Plastics

- Flexographic, Rotogravure Equipment

- Assembly Robots and EOAT

- Vacuum Metalizing Equipment

- Ink-jet Printers

- Bending, Heat-forming Equipment

- Ultrasonic Cutters

- Decorative Coatings

- Barrier Coatings

- Cutting Tools

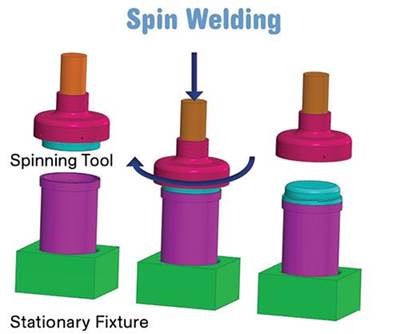

- Spin Welding

- Ultrasonic Welding

- Fasteners

- Spray Painting Robots and EOAT

- Dry Offset Printing Equipment

- Embossing Equipment

- Electrostatic Spray Equipment

- Sublimation Printing

- Screen-printing Equipment

- Vacuum Metalizing Materials

- Fluid-jet Cutting Systems

- Offset Lithography Equipment

- Other Paint Spray Equipment

- In-mold Coating Equipment

- Dielectric Welding

- Hot-air Welding

- Conductive Coatings

- Pad-printing Equipment

- Non-Heat-Transfer Decals

- In-mold Coatings

- Hot-stamping Presses, Other Heat-transfer Equipment

- Color Matching/Formulating Systems

- Tool Engraving, Texturing Equipment

- Plastics Engraving Equipment

- Adhesion Promoters (for Inks, Coatings)

- Heat Transfers (decals)

- Hot-stamping Foils

- Design of Experiments (DOE) Software

- Part or Sprue Removal Robots and EOAT

- Marking Equipment (including Laser Type)

- Antifog Coatings

- Electromagnetic Induction Bonding

- Laser Welding

- Linear Friction Welding

- Printing Plates, Cliches

- Abrasion Resistant Coatings

- Hot-stamp Tooling (including Silicone)

- Printing Inks

- Lasers (for Cutting, Machining, Welding)

- Staking, Inserting Equipment

- Heat Sealing/Welding

- Flame-resistant Coatings

- General Purpose Robots and EOAT

.png;maxWidth=300;quality=90)