FARREL POMINI

Farrel Corporation

One Farrel Boulevard

Ansonia, CT 06401 US

800-800-7290 | 203-736-5500

farrel-pomini.com

About FARREL POMINI

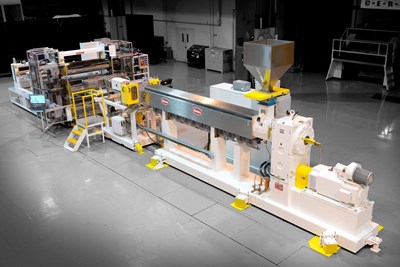

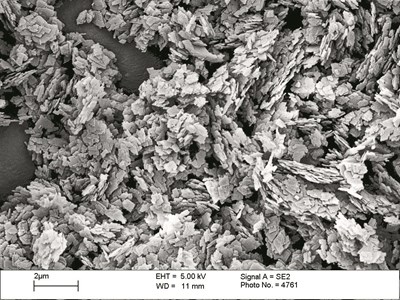

FARREL POMINI designs, manufactures and supports our unique technology continuous mixers for highly filled, abrasive and temperature sensitive applications. Our compounders offer superior energy & maintenance efficiencies, productivity, and accelerated return on investment.

IS THIS YOUR COMPANY?

As Seen On Plastics Technology

FARREL POMINI Supplies the Following Products

Trade Names Offered by FARREL POMINI

- FMP(TM) Farrel Melt Pump

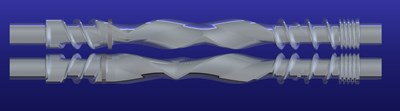

- FCM(TM) Continuous Mixer

- UMSD

- CPeX(R) Laboratory Compact Processo

- CP Series II(TM) Compact Processor