3D Printing Start-Up Competes with Injection Molding

A year-old company is devoted to large-scale custom 3D printing at prices competitive with injection molding to 20,000 parts.

A growing number of injection molders have adopted 3D printing for prototyping or making conceptual models to present to clients. Some are even making 3D-printed parts for internal use, such as jigs, fixtures, or robot grippers.

But few have pursued this technology as a means of commercial production of custom parts. For the most part, injection molders have left that field open to companies specializing in low-volume, high-value parts for aerospace and medical uses.

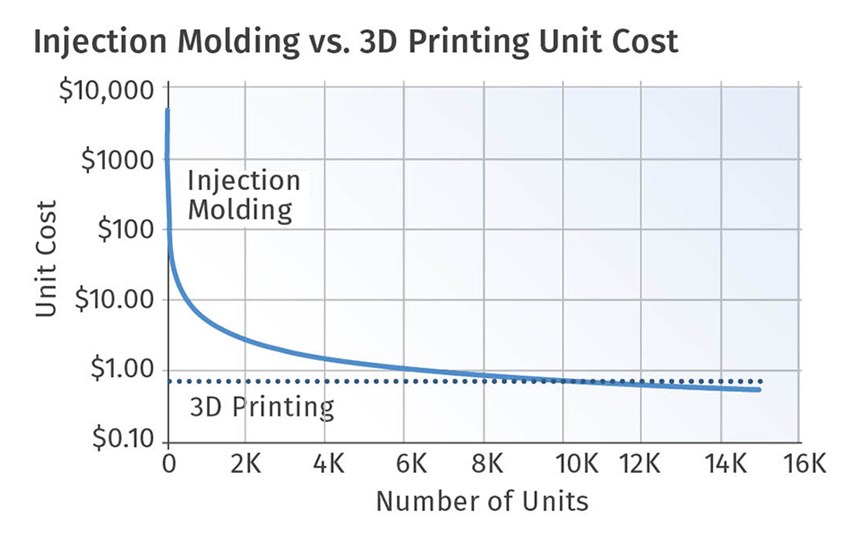

There are growing signs that injection molders need to watch their backs. Innovative start-up companies are emerging with large “farms” of 3D printers organized to compete with injection molding for orders of 10,000, 20,000, or even 100,000 parts. We reported in a September 2017 Close-Up on one example of this new type of competition, Voodoo Manufacturing in Brooklyn, N.Y. That article brought a response from a similar new venture, clear across the country. We were contacted by Gabe Bentz, president and founder of Slant Concepts in Nampa, Idaho. His mechanical design and engineering firm had spun off a second venture in October 2016, called Slant 3D, devoted to custom 3D printing in small to medium volumes. He claims it can produce parts that are less expensive than injection molding in volumes under 10,000 parts and reasonably competitive in price at up to 20,000 parts (see accompanying chart).

“We are working to make 3D printing a large-scale manufacturing option,” says Bentz. “We are doing this by developing hardware, software, and techniques to allow 3D-printing devices to produce parts in volume.”

HOME-MADE PRINTERS WITH AUTOMATION

Slant 3D operates a production printer “farm” with close to 100 printers, a number expected to grow to 500 in the next year or two. Bentz claims capacity to produce 5000 to 10,000 parts a week. His printers are self-manufactured to the firm’s own design.

They utilize an FDM-type of process in which extruded thermoplastic filaments are deposited in thin layers. Called the SlantBox, these “commoditized” printers are mounted in racks and all connected to the cloud for maximum productivity. They have a build volume of 10 by 8 by 9 in. and precision of 100 to 300 microns. They are designed to run continuously with much greater reliability than standard 3D printers. “We design them to be assembled and implemented quickly, but also rigid and tough enough to produce 95% good parts,” Bentz says. By addressing typical 3D manufacturing defects stemming from bed inconsistency or nonuniform extrusion rates, Bentz claims his production is more consistent from part to part and throughout an individual part than is commonly found in the market.

What’s more, he notes, his printers are fully automated so they can operate 24/7 without human intervention. “We have no need of robotic systems, because our printers remove the parts themselves (free dropped into bins) and are still lower cost to produce than most desktop 3D printer kits.” Bentz expects to begin marketing the SlantBox to others in the near future, at an anticipated price of $1000 to $1500.

Slant 3D’s primary material is PLA, though it also uses ABS and TPU to a lesser extent. Twelve colors are offered at present. His clients include robotics companies, architecture firms, and numerous companies looking for promotional items and prototypes in substantial volumes.

GOING AFTER INJECTION MOLDING

According to Bentz, price isn’t the only reason to consider 3D printing. “Traditional manufacturing techniques,” he says, “require high up-front expenses for tooling and long-term, high-volume production of a component to amortize those initial expenses. But if there is a mistake in the product, or the market changes, so that the product must be modified, companies may lose the entire investment in molds and tooling. This high risk also makes entry into high-volume production challenging for small or new businesses.

“3D printing allows an idea to go from conception to manufacture quickly and much more affordably. There are no tooling costs or lead time. A company wishing to produce a product need only design it and then pay for the raw materials used to produce it. 3D printing puts physical products on equal footing with software products in production costs. Printing allows products to be produced at very low cost and constantly updated with no large capital expenditures.”

All that’s necessary is to email Slant 3D a design file, and it can be put into production with little delay. However, Slant 3D also offers design services help get new products ready for production. Slant can do design consultation to judge printability and works with clients to tweak existing designs for optimum printability.

“3D printing puts physical products on equal footing with software products in production costs. They can be constantly updated with no large capital expenditures.”

Bentz concedes that surface smoothness is one area in which injection molding has an advantage over most 3D printing. Because 3D printed parts are typically produced in a sequence of layers, they can be weaker in the Z-direction than injection molded parts.

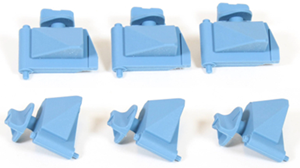

However, Slant 3D has produced some structural parts. The key, Bentz notes, is that such parts must be designed specifically for 3D printing, not simply converted from an injection molded design. He adds that 3D printing has advantages for making so-called “impossible” parts. An example is the gear shafts shown in the photo above. They are built around a metal bearing, making the entire assembly effectively a single part.

Injection molded parts for this assembly would have to be designed to interlock and pull apart so that a bearing could be inserted. In this case, what is now manufactured as a single assembly would have to be split into the gear, toothed pulley, shaft, and metal bearing, all of which would be manufactured separately and then assembled together.

But since this part was 3D printed, the gear, pulley, and shaft were combined into a single part. During production, the build would pause to insert the metal bearing. Then the build would continue and the part would be built around the bearing.

3D printing reduced four parts to two. Manufacturing cost was dramatically reduced because there was no assembly and none of the tooling that would have been required for the three plastic parts combined with the bearing. Slant 3D is using this approach to develop a “fidget spinner” with an internal bearing.

Bentz will give a talk on 3D printing at Plastics Technology’s Molding 2018 Conference, Feb. 27-Mar. 1 in Long Beach, Calif. A representative of Voodoo Manufacturing will also speak there. Details and registration are at moldingconference.com.

Related Content

Daimler, OMIC Evaluate Wire-Fed DED for Moldmaking

3D printing a core and cavity on machine from Gefertec, followed by machining, allowed for a complete mold tool to be produced in three days.

Read MoreGetting into Plastics Additive Manufacturing? Avoid these Six Common Errors

There are a lot of 3D printing technologies out there, and it’s not uncommon for processors new to additive manufacturing to get tripped up. Here are some typical snafus, along with advice on how to avoid them before you start making parts.

Read MoreMedical Manufacturer Innovates with Additive Manufacturing and Extrusion Technology Hubs

Spectrum Plastics Group offers customers two technology hubs — one for extrusion, the other for additive manufacturing — to help bring ground-breaking products to market faster.

Read MoreBusiness Slowing? There's Still Plenty of Stuff to Do

There are things you may have put off when you were occupied with shipping parts to customers. Maybe it’s time to put some of them on the front burner.

Read MoreRead Next

Processor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read More