Add Automation to Your Lab

Robots are commonplace on the production floor, cutting costs and improving efficiencies for molders and other processors. Now, those same benefits can also be achieved in the lab.

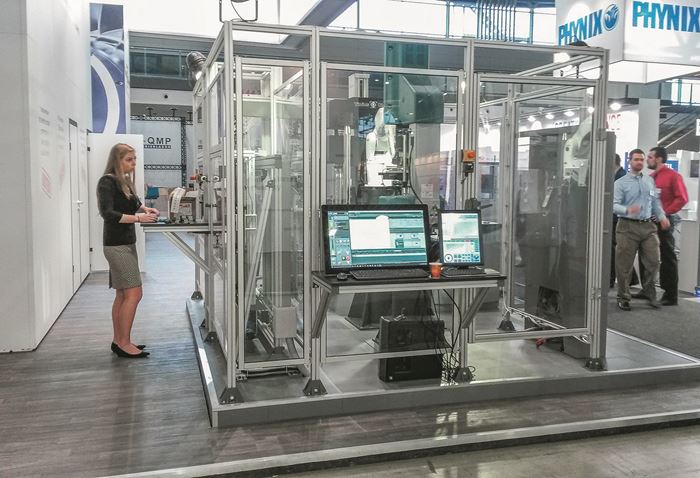

Automation has taken off in plastics processing plants, with molders and other processors turning to robots on the production floor to lower costs and improve efficiencies. But what about the lab? Is a scalable, fully automated system for materials testing feasible? It is, meaning that—just like on the plant floor—operators can be freed to perform other types of quality tests while the automated system, with robotic arms in enclosed cells at its core, gets on with the task of testing any size of specimen batches.

Nowadays, robots in the lab can be deployed to perform a range of tasks, testing anything from packaging containers to medical drug dispensers. Tests can be conducted without the need for human intervention, operating on a 24/7 basis. Traditionally, semi-automatic testing has been used primarily in large industrial metals plants, leaving other businesses like per 24 hr watching and waiting for tests to run. By contrast, a robotic system for materials testing can continue running all day and night, leading to productivity gains versus an operator of 59 hr a week, or 127 days over the course of a year.

Automation of testing is not just for plants that test hundreds or thousands of specimens a day. If you put a machine in a cell and automate the specimen handling, productivity increases are gained across the board.

Take this real-world example of a medical molder testing drug-dispensing devices: This company conducted tests at three individual stations, with groups of lab operators spending 24 hr a day loading, testing, and removing the parts. Now, this is all completely automated. In another case, a global company that’s in the business of rubber and plastics testing has already automated tensile, flexural modulus, and compression testing, and is now looking to see if it can further automate the whole process.

Automated testing also reduces the chance of worker error caused by boredom and fatigue when performing a large number of repetitive tasks. Unlike people, a robot does not lose interest. Advanced automation systems are not limited to just one test. Systems can be designed to run multiple tasks of any size and combination of tests, increasing efficiency and speed.

Scalable building-block approaches to automation allow systems to be supplied from very low-force applications (just a few newtons) to very high-force applications of a thousand kilonewtons or more. They can also use a single specimen-handling system with a robotic arm to feed more than one testing machine.

With the latest technology, you can perform tensile testing on one machine and flex on another; or there could be two testing machines working on fastener testing, feeding, and managing; or there could be a Rockwell hardness tester and a tensile-test machine working together. For the example of a drug-delivery device, needle puncture force can be tested on one station and the drug-dispensing pressure in another.

More Questions About Testing? Visit the Testing & Quality Control Zone

Automated systems have been years in the making, and today’s technology can be scaled up or down to meet any requirement. Technology available on smartphones and tablets also means the robots and testing stations can be viewed remotely by managers anywhere. Test parts are ejected from the cell and the whole process, with pass/fail results, can be monitored remotely in real time, with an industrial camera inside the cell that can be accessed 24 hr a day via a manager’s mobile phone or tablet to check that everything is working smoothly.

With the building-block concept and the scalability, automation of materials testing is now viable for plastics processors who may have thought they needed a certain production volume to move away from manual testing. They can now benefit from productivity and repeatability, every hour of every week of every day, whoever and wherever they are.

ABOUT THE AUTHOR: Shawn Byrd is technical manager at Tinius Olsen Testing Machine Co., Inc., Horsham, Pa., focusing on materials testing and the application of various standards to different testing platforms to assist in the evaluation of materials and products. He has worked with testing labs in the U.S., China, India, and Singapore He is also a member of various ASTM International Committees, which collectively are responsible for 204 standards. Byrd is also involved with ASTM on collaborative projects with colleges and industries. Contact: 215-675-7100; sbyrd@tiniusolsen.com; tiniusolsen.com.

Related Content

What to Look for in High-Speed Automation for Pipette Production

Automation is a must-have for molders of pipettes. Make sure your supplier provides assurances of throughput and output, manpower utilization, floor space consumption and payback period.

Read MoreDigital Manufacturing: Two Medical Molders Embrace Industry 4.0

‘Digitalization’ and ‘connectivity’ are loaded terms—shorthand for a whole new way of doing business. It can’t be accomplished in one go. But two Midwest molders in the sensitive medical field are already feeling the benefits of their initial steps in that direction.

Read MorePursuing Paperless: Injection Molders Who Have Embraced Digitization

Read about injection molders who have shifted everything from quality control and scheduling to production and process monitoring to the digital realm.

Read MoreProduction Monitoring Automates Molder’s Planning, Operations

DCT saves 60 man-hours per week by shifting from paper records and discrete spreadsheets to a shared, automatic production monitoring platform.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More