Bringing Order to the Chaotic Debate of Turbulent Flow in Injection Molding

Is turbulent flow required for all cooling channels to optimize the cooling process in injection molding? It depends. Author reviews the Reynolds number, advanced cooling technologies, simulation’s potential role and more.

Attention to cooling line optimization of injection molds has increased in recent years. With the rise of technologies like conformal cooling and injection molding simulation, as well as the increased use of alloys, designers have a greater ability to achieve better cooling for their molds. To reap the full benefits of the cooling line layout, reduce cycle time and increase yield, molders and designers need to make sure the cooling setup is operating as efficiently as possible.

Generally speaking, that means you’re achieving turbulent flow in all the cooling channels that are actively cooling the part. While it’s usually agreed that turbulent flow is needed, a debate can often arise on what’s sufficient flow to get acceptable cooling of the parts. This article will highlight the

The mold surface temperature (Tp/m) is controlled by the positioning of the cooling lines relative to the mold surface, and the conditions under which the coolant flows through the cooling channel. Often one of the limiting factors of mold cooling is how efficiently the heat can be transferred from the mold steel into the coolant fluid. Source: The Madison Group

benefits of turbulent flow for the optimization of the cooling stage, and how you can better understand how it may affect your part performance.

Feeling the Flow

When we talk about flow in injection molding, the discussion typically revolves around polymer flow. Polymers are very high-viscosity fluids that only exhibit laminar flow within the cavity. This means that as the polymer flows into the cavity, it flows in distinct layers that do not mix as they progress into the cavity. However, when it comes to controlling the temperature of the mold, a lower viscosity fluid, like water or oil, is flowing through the cooling channels.

The surface temperature of the mold is controlled by the position of the cooling channel relative to the surface of the mold; the temperature of the fluid passing through that cooling channel; and how quickly the coolant fluid is flowing through the cooling channel (Figure 1). There are many design textbooks that provide guidance on the suggested distance of the cooling lines from the mold surface and the spacing of the cooling lines relative to one another to help achieve relatively uniform heat extraction at the mold surface without sacrificing mold integrity.

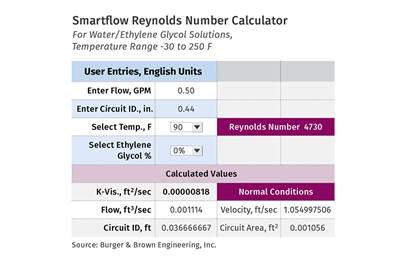

However, the discussion regarding how much coolant should pass through the cooling channels is often simplified to: “Ensure the flow is turbulent.” Generally, characterization of the type of flow is described by the dimensionless number designated as the Reynolds number. The equation below shows that the Reynolds number is directly proportional to the coolant fluid velocity and density, as well as the cooling line diameter.

It’s also inversely proportional to the dynamic viscosity of the coolant fluid. If you can transition from laminar flow (Re<2,300) into turbulent flow (Re>4,000), the ability of our coolant fluid to extract heat from the mold is substantially increased.

This generally results in mold surface temperatures that are closer to your coolant temperature and an overall more uniform mold surface temperature, as shown in Figure 3.

Graph shows how the convective heat transfer at the cooling channel wall increases substantially when the coolant flow transitions from laminar to transient. Source: Covestro

Images highlight that when the flow in the cooling channels is turbulent (bottom row), the mold surface temperature is generally lower and more uniform, which leads to more efficient cooling and faster cycle times. Source: The Madison Group

Turbulence Ahead

While there’s no doubting the benefits of turbulent flow, the question is: Can you achieve this flow in the cooling circuits that are actively cooling your part? Additionally, when multiple circuits are connected to the same temperature control unit, will all the circuits get enough coolant flow to reach the turbulent flow regime?

Figure 2 highlights that when connected to a temperature control unit, it’s relatively easy to get a lot of flow in standard gundrilled lines and even cooling circuits with baffles. These circuits generally have larger diameter flow channels that do not require much pressure at the temperature control unit to move the coolant through these circuits and achieve turbulence. However, when you start integrating features like bubblers and conformal cooling channels that can decrease your flow channel diameter and increase the flow length in the cooling circuit, it can be much more difficult to achieve flow rates that will enable turbulent flow.

Image highlights how incorporating advanced cooling features like conformal cooling and bubblers can lead to lower flow rates that might not be able to achieve turbulent flow. Source: MGS Mfg. Group

Injection molding simulation packages, like Autodesk Moldflow, can help answer some questions about how much flow is required to achieve turbulent flow in each of the circuits, and how much pressure is required to achieve those flow rates. A molder or a tool designer can use this information to help determine how many cooling line connections are needed in the mold, and what size and number of temperature control units are required.

Bubblers and conformal cooling channels can decrease the flow channel diameter, increase the cooling circuit’s flow length and make it more difficult to achieve flow rates enabling turbulent flow.

Decisions can be make by looking at the pressure required to achieve the desired flow rates for turbulent flow across different circuits. If there is a large difference in the required pressure to achieve the desired flow rates in different circuits, that suggests that the higher-pressure lines should be fed by a different temperature control unit, or that the manifold should be manipulated to help push more fluid into that higher pressure line.

Finally, performing the simulation allows the designer to see how the coolant temperature heats up as it passes through the mold for each circuit. This provides much more insight than just monitoring the water temperature at the inlet and outlet of the temperature control unit, as is commonly performed in production environments.

So How Much Flow Is Enough?

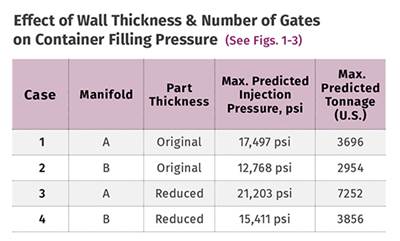

To help answer the question of how different flow rates affect the part quality, a molding study was performed on a multicavity mold for a medical device housing. The housing material was an unfilled polypropylene copolymer. In the study, the process parameters and cycle time were unchanged, but the amount of water flowing into the cooling circuits was manipulated to achieve either laminar or turbulent flow at the inlet of the cooling circuits. A description of the different processes is shown in the table above.

The results of the study suggest that as long as the flows remained in the transitional or turbulent regime, the overall dimensional stability of the part was not affected. Figure 4 shows how the overall height (Dimension 2A) remained relatively centered across all processes except for Process 4, where the flow in all the circuits was either transitional or laminar. The study found that the width of the housing was sensitive to the core cooling channel flow differences. When the flow in the core (bubbler) circuit reverted to a laminar flow, the width of the part decreased and exhibited the typical “oil-canning” geometry, which could cause assembly issues.

In summary, it’s important for molders and tool designers to consider the conditions under which their cooling line layout may run. While it’s great to incorporate advanced cooling features like conformal cooling or bubblers, it’s important that these circuits are able to achieve a turbulent flow so you can develop a consistent process. However, it’s not always necessary to achieve a critical Reynolds number within the turbulent regime to establish a stable process. Using tools like injection molding simulation can help identify potential issues early on and enable mold designers and molders to make the right decisions on how to maximize the efficiency of a mold design.

ABOUT THE AUTHOR: Erik Foltz is a certified professional Moldflow consultant at The Madison Group. Foltz received his master’s degree from the Polymer Engineering Center at the University of Wisconsin – Madison. His specialties include plastic part design verification, process optimization and troubleshooting for injection and compression molding, as well as plastics failure. Contact: 608-231-1907; erik@madisongroup.com; madisongroup.com.

Related Content

Using Data to Pinpoint Cosmetic Defect Causes in Injection Molded Parts

Taking a step back and identifying the root cause of a cosmetic flaw can help molders focus on what corrective actions need to be taken.

Read MoreUse These 7 Parameters to Unravel the Melt Temperature Mystery

Despite its integral role in a stable process and consistent parts, true melt temperature in injection molding can be an enigma. Learning more about these seven parameters may help you solve the puzzle.

Read MoreMedical Tubing: Use Simulation to Troubleshoot, Optimize Processing & Dies

Extrusion simulations can be useful in anticipating issues and running “what-if” scenarios to size extruders and design dies for extrusion projects. It should be used at early stages of any project to avoid trial and error and remaking tooling.

Read MoreInjection Molding: Focus on these Seven Areas to Set a Preventive Maintenance Schedule

Performing fundamental maintenance inspections frequently assures press longevity and process stability. Here’s a checklist to help you stay on top of seven key systems.

Read MoreRead Next

Cooling Geometry and the Reynolds Calculation

The original Turbulent Flow Rate Calculator worked well with a round circuit diameter, such as a drilled passage, but not as well using hydraulic diameters. Here’s how the problem was fixed.

Read MoreWhen Injection Molding Simulation Can Be a Great Troubleshooting Tool

Injection molding simulation can serve as a powerful tool not just for design but also for ongoing production optimization.

Read MoreINJECTION MOLDING: The Importance of Nominal Wall For Lightweighting Molded Parts

Establishing a nominal wall is one of the most important decisions an engineer makes when designing parts. Understanding how design changes will impact the manufacturing process is critical to ensure the part performs as expected.

Read More