Calculate Shot Size Vs. Barrel Capacity

It may seem like a dull topic, but it will overcome the emotional experience that follows when you put a new mold into a machine and you find out there is not enough barrel capacity to make a full shot.

Calculating shot volume to make sure your barrel has enough capacity may seem like a dull topic, but it will overcome the emotional experience that follows when you put a new mold into a machine and you find out there is not enough barrel capacity to make a full shot.

Now I’m sure this has never happened to you, but a few of us have been in this spot. So as not to emulate our mistakes, you need to do your homework before the machine is ordered. Not having a properly sized barrel for your shot is a show (and a part) stopper.

How do you figure out what barrel size you’ll need?

How do you figure out what barrel size you’ll need? If it is a new part and your mold hasn’t been built yet, running a mold-filling analysis will give you the volume of the part and runner. If your mold is in the building stage, your moldmaker may have calculated the volume of your shot—and make sure to also include the runner volume if it’s a cold-runner mold. If you already have the mold and you are purchasing a new machine, you have two sets of data: the part and runner weights, plus the shot size of the existing machine. With either part and runner weight, or the volume of the total shot, you have your starting point.

Let’s start with the scenario in which you know the part weight. I like to work in grams but most machine specifications are in ounces. If the part, runner (cold), and sprue together weigh 164 g, the equivalent is 182.2 cc of PP (at 0.90 g/cc density), or 6.16 oz (1 cc = 0.0338 oz). Assuming you have a barrel capacity of 8 oz, you might be tempted to conclude that you have plenty of shot volume. Unfortunately this is where things start to unravel.

First, what if the machine-capacity specification in ounces is for one material, often polystyrene, and you are running polypropylene? (Note: Many machine specs today quote barrel capacity both for PS and HDPE.) There is an important density difference between these resins. At room temperature the density of PS is 1.04 g/cm3 and PP has a room-temperature density 0.90 g/cm3. You might then think, “Okay, for my 6.16 oz of PP you can take the ratio of densities 1.04/0.90 or 1.16 and arrive at a required barrel capacity of 7.14 oz.” With an 8-oz barrel you’re still okay, right?

Don’t forget that solid polymer density is different from melt density.

Unfortunately, this is when Mr. Murphy usually knocks with his lesson that what can go wrong usually does. He’ll remind you that these are room-temperature densities, and in molding we deal in melt-temperature conditions. Sorry, there’s another step of complexity: dealing with melt densities.

When melted, the polymer molecules are farther apart and density decreases. The problem is that melt-density data is harder to come by. It is not on many material specification sheets and you have to do a bit of research to find it. (Plastics Technology’s Universal Selector is one place to check).

For PS the melt density is 0.945 g/cm3 and for PP it is about 0.74 g/cm3. This changes the ratio for our calculation; it is now 0.945/0.74 or 1.28. Now we need a minimum of 6.16 x 1.28 or 7.88 oz of shot capacity. We are still (just barely) within our 8-oz barrel capacity, but unfortunately Mr. Murphy is still lurking.

Consider our check valve: It leaks! Is it practical to try to use 98% of the barrel capacity (7.88/8.0 oz)? Not in my book, and you need some cushion and room for decompression—especially for hot runners. I recommend shot-sizes of 25% to 70% of barrel capacity. If we add all this up, plus a 10% safety factor for check-valve leakage, cushion, and decompression and to ensure uniformly melted plastic, we need a barrel with at least 11-12 oz capacity.

How big a shot can your screw melt uniformly?

But we’re not done yet. We have to think about plasticating capacity. PP is a semi-crystalline resin and it melts differently, perhaps more stubbornly, than amorphous resins. Generally, semi-crystalline resins stay hard up to their melting point and often require twice as many BTUs to melt as amorphous resins. This double whammy makes semi-crystalline resins significantly harder to melt uniformly than amorphous ones. You don’t want to use too much of your barrel capacity, or you’d be running the risk of having unmelted or partially melted solids in the melt stream. Warpage, shrinkage, and physical properties would be significantly affected.

Once again, you do not want to underestimate this detail of properly calculating shot size vs. barrel capacity. Too much is at stake. Send me your email address and I’ll send you a spreadsheet to do this calculation. You plug in ounces or grams and resin melt density, then it calculates the suggested barrel capacity in ounces.

The next task will be to determine if your screw can melt this shot within the quoted cycle time. That’s for the next column.

ABOUT THE AUTHOR: John Bozzelli is the founder of Injection Molding Solutions (Scientific Molding) in Midland, Mich., a provider of training and consulting services to injection molders, including LIMS, and other specialties. Contact john@scientificmolding.com.

Related Content

What to Look for in High-Speed Automation for Pipette Production

Automation is a must-have for molders of pipettes. Make sure your supplier provides assurances of throughput and output, manpower utilization, floor space consumption and payback period.

Read MoreThree Key Decisions for an Optimal Ejection System

When determining the best ejection option for a tool, molders must consider the ejector’s surface area, location and style.

Read MoreInjection Molding: Focus on these Seven Areas to Set a Preventive Maintenance Schedule

Performing fundamental maintenance inspections frequently assures press longevity and process stability. Here’s a checklist to help you stay on top of seven key systems.

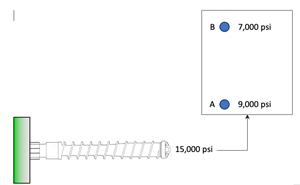

Read MoreUnderstanding the Effect of Pressure Losses on Injection Molded Parts

The compressibility of plastics as a class of materials means the pressure punched into the machine control and the pressure the melt experiences at the end of fill within the mold will be very different. What does this difference mean for process consistency and part quality?

Read MoreRead Next

A Simpler Way to Calculate Shot Size vs. Barrel Capacity

Let’s take another look at this seemingly dull but oh-so-crucial topic.

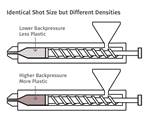

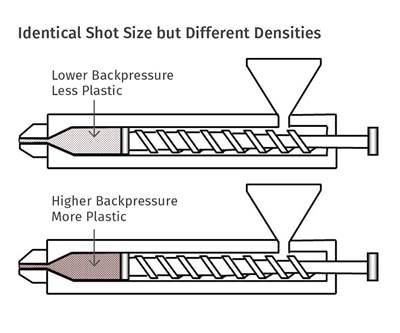

Read MoreInjection Molding: How Backpressure Adjustments Influence Shot Size

Raising backpressure results in increasing shot size, which can cause a host of other problems.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More

.jpg;width=70;height=70;mode=crop)