Injection Molding: How Backpressure Adjustments Influence Shot Size

Raising backpressure results in increasing shot size, which can cause a host of other problems.

A processor has vast trove of processing “handles” available on today’s injection molding machines. Often they seem simple enough, especially if you change one machine parameter at a time. The problem is that when you change one setting on the machine controller it often influences two or more different process conditions.

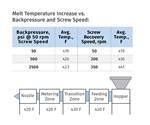

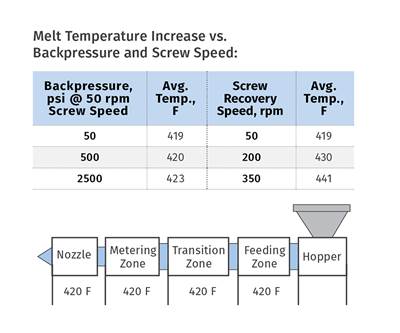

In a previous column discussing backpressure and its influence on temperature (Nov. ’17), I left out an important process change. A former student of mine, Seng Lo of Hellerman Tyton Americas, emailed me to point this out. Worse yet, it was not included in the list of “why we need backpressure” that was published in that issue.

So, in the interest of completeness, why do we need backpressure?

Reasons include:

- Better melt-temperature control (not increase melt temperature);

- Better melt uniformity in consistency and temperature;

- Better blending in colors or additives at the press, if you are running a correctly designed screw;

- Better shot-size position control;

- Better filling of the flights to prevent black specks and degradation where the flights meet the root diameter of the screw;

- Prevent screw augering due to pellets being wedged between flight land and feed throat (a problem for smaller screws in particular);

- Control of shot size (this is the one I missed).

How does backpressure control shot size, and what does a change in backpressure change in your molding process? Processing is not just about understanding the machine; a good processor knows how plastics behave. In this case, they have to understand that molten plastic is compressible. For example, room-temperature or solid density for HDPE is 0.957 g/cc, while its melt density is 0.759 g/cc, or less than 80% of its solid density. This means the polymer molecules are farther apart from one another in the molten state, and at typical backpressures the molten HDPE can be compressed. Typical backpressures (plastic not hydraulic pressures) for most resins are in the range of 300 psi to about 1500 psi (20-103 bar). These pressures do compress the melt.

To illustrate this effect, let us review a common issue on the shop floor: short shots. It is not unusual for a process to be running fine, and then when a new color or lot or some other change in the system occurs, the result is periodic short shots. As my November column noted, some processors may decide to raise the melt temperature to fix the shorts. To speed this along,

Know How Injection Molding: Get More Insights from our Expert Authors

Crusty (my fictitious grumpy old processor) adds a bit more backpressure to get the temperature to increase faster. That is, before he or she read my previous article, which provided data that proved backpressure does not increase melt temperature.

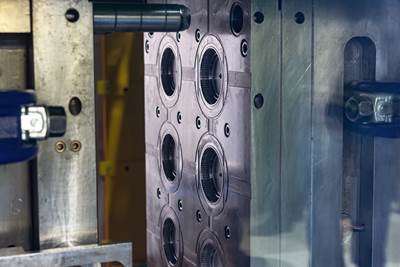

It may seem as though raising backpressure increases temperature because the short shots stop. The rationale here is that the higher temperature lower the viscosity, making the short shots disappear. But that’s not the case. Yes, the parts are full, but not because of an increase in melt temperature or lower viscosity, but because more plastic is packed (at higher density) into the same shot size (see illustration p. 36). If density is higher, there is more plastic in the same volume or shot size. It is not a temperature effect but a density change that provides more plastic in the same shot volume. The shot size changes without any change of screw position.

Over-pressurizing the cavity wears the parting line, which eventually results in flash.

Dubious? Then check it out for yourself. The proper procedure for a change in backpressure is to take off second-stage pack and hold, change the backpressure, then note how full the cavity is. Most likely you will need to re-establish the same fill volume for the parts by hanging the cutoff position. This is critical if you want apples-to-apples comparisons for DOEs. Why? In the example above, you have what you wanted, full parts. The problem is that you changed the shot size and now that extra material put in during first-stage fill may be packing out the part in that first stage.

This overpressurizes the cavity, which in turn wears the parting line, which eventually results in flash. Now you have an even bigger problem. Bottom line: always think things through. Whenever you change a process parameter ask yourself four questions:

- Did this change the melt or mold temperature,and what will be the result?

- Did this change the plastic pressure of the melt, and what is the result?

- Did this change the plastic flow rate, and what is the result?

- Did this change the cooling rate or time, and if so what is the result?

Related Reading: How Backpressure Affects Melt Preparation

ABOUT THE AUTHOR: John Bozzelli is the founder of Injection Molding Solutions (Scientific Molding) in Midland, Mich., a provider of training and consulting services to injection molders, including LIMS, and other specialties. Contact john@scientificmolding.com.

Related Content

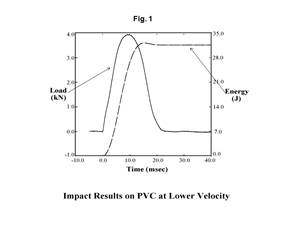

The Strain Rate Effect

The rate of loading for a plastic material is a key component of how we perceive its performance.

Read MoreHow to Stop Flash

Flashing of a part can occur for several reasons—from variations in the process or material to tooling trouble.

Read MoreTunnel Gates for Mold Designers, Part 1

Of all the gate types, tunnel gates are the most misunderstood. Here’s what you need to know to choose the best design for your application.

Read MoreImprove The Cooling Performance Of Your Molds

Need to figure out your mold-cooling energy requirements for the various polymers you run? What about sizing cooling circuits so they provide adequate cooling capacity? Learn the tricks of the trade here.

Read MoreRead Next

A Simpler Way to Calculate Shot Size vs. Barrel Capacity

Let’s take another look at this seemingly dull but oh-so-crucial topic.

Read MoreInjection Molding: No, Backpressure Does NOT Raise Melt Temperature

It’s a classic confusion between cause and effect. Melt temperature rises when screw speed is increased. Check out this data.

Read More.jpg;width=70;height=70;mode=crop)