Don't Get Burned by Adapters & Flow Pipes

Does degraded or burned polymer seem to show up when you least expect it?

Does degraded or burned polymer seem to show up when you least expect it? If so, it’s probably coming from one of your adapters or coextrusion flow pipes. While only very badly designed screws and dies will cause polymer to degrade during processing, the same cannot be said of adapters and flow pipes. Complicating matters is a design “catch 22” concerning these components. Typically they are designed to minimize pressure drop, yet minimum velocities must be maintained inside the flow channels to continuously clean the walls. These two design considerations are contradictory because the larger the channel, the lower the pressure drop—and the lower the velocity.

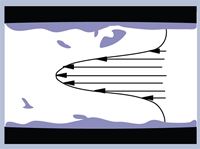

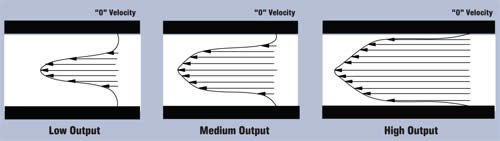

Every polymer will have its own velocity profile shape in the channel, depending on its melt characteristics. All are parabolic in general shape, but some are rather blunt while others are pointed. As the channel gets larger, or as the flow rate is reduced, the major portion of the flow becomes more centered in the channel while the polymer near the walls moves slower.

There is always a static layer of polymer adhering to the flow-channel wall, but it’s necessary to maximize the flow adjacent that layer to help its gradual renewal. As the flow rate drops, there is a corresponding increase in the portion of the polymer that is moving very slowly or even stops. In close proximity to the continuously heated surface of the adapter or flow pipe, the slow-moving polymer is subjected to a very long heat history and slowly degrades, eventually turning to a carbon-like material. The degraded polymer loses its flow properties and a completely static layer builds on the channel inner wall. This layer becomes brittle and extrusion pressure occasionally breaks off bits that pass along with the melt. These tend to come out all at once or in “showers.” This happens most often when the output is increased or some other process change occurs.

If such issues occur, it is not necessarily due to an error by the machinery designer. More likely it’s because the equipment was designed for a much higher output than is currently being run, resulting in lower than anticipated flow velocity. As with many polymer flow issues, this can be investigated by calculating the shear stress at the wall. Data required are a shear rate/viscosity plot at the melt temperature and the dimensions of the flow channel. This can be a relatively easy calculation when using Newtonian formulas and the actual viscosity data. Minimum shear-stress levels required to maintain clean channel walls have been determined pretty much by trial and error but generally are quite consistent.

Operators often try to correct the problem of buildup of degraded polymer by lowering the temperature of the adapters or flow pipes. Generally this makes matters worse as it increases the initial static layer thickness, and even though the temperature is lower it is still more than enough to eventually degrade the polymer. The only complete solution is to match the flow channel diameter to the output so as to keep the channel as nearly full as possible while controlling pressure drop. Sometimes to control pressure drop will require shortening the flow channels, necessitating changing the position of some equipment. This same situation applies to any portion of the polymer flow channels from the exit of the extruder to the exit of the die.

About the Author

Jim Frankland is a mechanical engineer who has been involved in all types of extrusion processing for more than 40 years. He is now president of Frankland Plastics Consulting, LLC. Contact jim.frankland@comcast.net or (724)651-9196.

Related Content

How to Select the Right Tool Steel for Mold Cavities

With cavity steel or alloy selection there are many variables that can dictate the best option.

Read MoreDensity & Molecular Weight in Polyethylene

This so-called 'commodity' material is actually quite complex, making selecting the right type a challenge.

Read MoreHow to Stop Flash

Flashing of a part can occur for several reasons—from variations in the process or material to tooling trouble.

Read MoreThe Importance of Melt & Mold Temperature

Molders should realize how significantly process conditions can influence the final properties of the part.

Read MoreRead Next

Understanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreAdvanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read More

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)