Exotic Bottle Shapes Push the Limit

It takes some nerve and a lot of know-how to be on the cutting edge of blow molding today.

It takes some nerve and a lot of know-how to be on the cutting edge of blow molding today. Food and beverage makers are looking for more complex and innovative bottle designs to differentiate their brands and attract attention in the display case or on the store shelf. As a result, stretch-blow molders of PET and polypropylene are taking oriented bottles to a new level, producing novel designs that were previously unattainable.

Striking fruit juice

Perhaps the most remarkable shape in the new crop of food and beverage bottles is the stacked spheres that define the pomegranate juice container for POM Wonderful of Los Angeles. The firm shifted from glass to PET in 16- and 24-oz sizes. While acknowledging the complexity of this job, molder Graham Packaging Co. in York, Pa., declined to discuss details of the proprietary technology, which included a special preform design and blowing techniques.

Sports drink gets a grip

A new hot-fill PET bottle for Powerade sports drink from Atlanta-based Coca-Cola North America does not use conventional panels to take up the vacuum when the product cools. In this innovative design, the panels are a deliberate aesthetic feature not hidden by the label.

The easy-grip 20-oz bottle boasts a tight-fitting, roll-fed shrink label made of oriented PP. The tight fit prevents liquid from getting trapped under the label and making the bottle hard to grip, a common problem in sports-drink packaging. Coca-Cola would not identify its two suppliers for the bottle, but says no unusual preform design or bottle blowing techniques were required.

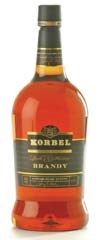

Hefty preform feels rich

A heavier preform is among several key features in a unique glass-like design for Korbel Classic Brandy's new 1.75-liter stretch-blown PET bottle from Amcor PET Packaging, Ann Arbor, Mich. The bottle's sloped shoulders and subtle pedestal base are produced from a 92-g preform with a 33-mm Kerr short finish. The preform is heavier than the average 80- to 83-g preform used for 1.75L liquor bottles, giving the bottle extra heft to enhance the perceived value of the product.

Fred Piercy, Amcor's business director for liquor packaging, said the thick-walled preforms required special reheating and stretching techniques to maintain production speeds typical of similar-size bottles. In addition, the supplier took precautions during post-blowing operations to minimize scuffing and maintain the glass-like appearance.

Shrink film takes off

When is a ketchup bottle more than a package? When it's a toy, which is what happens to the Ketchup Kids Rocket bottle when it's empty. The 220-g stretch-blown bottle from Brazilian food maker Sofruta has plenty of complexity—a transition from square to oval and an asymmetric conical shape to boot.

There's more to it than just the bottle. A decorative film from Sleever International in France (Sleever Canada is in Mississauga, Ont.) completely encapsulates the package with a tight fit. Sleever's 40-micron SI-OPS/TF-040 OPS film provides a high shrink rate (50%), resulting in a complete decoration of the conical bottle over the entire 360° surface. Three-dimensional morphing techniques allow both text and eight-color graphics to be reproduced with high accuracy, even in areas of high shrinkage.

Related Content

How Was K 2022 for Blow Molding?

Over a dozen companies emphasized sustainability with use of foam and recycle, lightweighting and energy savings, along with new capabilities in controls, automation and quick changeovers.

Read MoreAvoid Four Common Traps In Granulation

Today, more than ever, granulation is an important step in the total production process. Our expert explains a few of the many common traps to avoid when thinking about granulators

Read MoreAt NPE, Cypet to Show Latest Achievements in Large PET Containers

Maker of one-stage ISBM machines will show off new sizes and styles of handled and stackable PET containers, including novel interlocking products.

Read More50 Years of Headlines … Almost

I was lucky to get an early look at many of the past half-century’s exciting developments in plastics. Here’s a selection.

Read MoreRead Next

Processor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read More

.png;maxWidth=300;quality=90)