Extrusion Know-How: The Whys & Hows (& Ifs) of Vented Extruders

Vented or two-stage screws only make sense when volatiles must be removed in order to make a satisfactory product.

Vented or two-stage screws only make sense when volatiles must be removed in order to make a satisfactory product. These screws have a number of disadvantages that are offset only if volatile removal is essential to proper operation. First and foremost is the problem of vent leakage. Second is a loss of output due to the need to design the screw to accommodate an open vent. Third, there is always a likelihood of contamination developing from the unfilled flights in the vent. Finally, vented screws can be unstable if the final metering section is not adequately filled.

How does a vented screw function? First, it reduces the melt pressure to atmospheric, so there is no tendency for the polymer to be pumped out the vent opening. That is accomplished by increasing the channel volume so that the output of the extruder only partially fills the flights under the vent.

A vented or two-stage screw is essentially two screws on the same shaft. The first works as a conventional screw by feeding, melting, and conveying the polymer forward. The second screw does the same, except it is melt-fed by the first screw. The first screw operates with no head pressure, while the second has to overcome any head pressure from the die and other downstream components. In order to keep the vent section of the screw from filling and developing vent flow, the second screw must have more output capacity than the first screw. Proper design of a two-stage screw requires knowledge of the polymer viscosity, the output capacity of both stages, and the head pressure. Simply using a ratio in channel depths between the first and second metering sections is risky.

Proper venting with no leakage or vent flow does not depend solely on the design of the screw. The barrel vent opening has to be fitted with a contoured plug called a diverter. The diverter deflects polymer away from the opening or else it will quickly become filled with melt. Its design is more of an art than a science but there are many variations that work, all using the same principles.

It is obvious that the screw has to be partially filled or the diverter cavity would be overcome with polymer, which would block the opening. However, there has to be some polymer touching the barrel wall or there will be no forwarding of the material. The polymer does not simply lay down in the screw channel, so there is always a necessary balance between the volume of the diverter cavity and the width of the melt bank, which is proportional to the output of the first stage of the screw. The shape of the bank depends on the polymer viscosity, but in general, if the portion of melt touching the barrel wall exceeds one-third of the channel width, there will be difficulty keeping the vent open.

Most vents are located on the left side of the extruder (looking downstream). Top vents work well but in case of any vent flow, the melt will run all over the barrel and is hard to access. A right-hand vent would have gravity pulling the residual material left in the diverter cavity down into the opening, making it more difficult to maintain an open vent, particularly when the extruder stops.

In my experience, vent flow is more frequently caused by the design of the diverter than that of the screw. You can often tell what the problem is by watching the material flow out of the vent. A screw design that has too much polymer in the vent area will tend to extrude material in a steady stream out the vent. A diverter that is not properly designed will tend to show a pulsing action that corresponds perfectly with the screw speed.

Design of the vent section of the screw can be optimized for removing volatiles in applications such as devolatilizing printed films and resins that are highly hygroscopic. Another approach is to make a three-stage screw with two vent sections, thereby doubling the devolatilizing area. Also, vacuum pumps can be applied to the vent to remove residual volatiles with low vapor pressure.

About the Author

Jim Frankland is a mechanical engineer who has been involved in all types of extrusion processing for more than 40 years. He is now president of Frankland Plastics Consulting, LLC. Contact jim.frankland@comcast.net or (724)651-9196.

Related Content

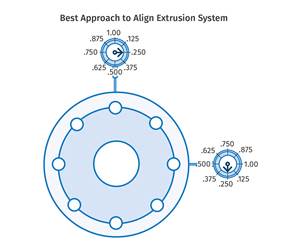

Extruder Alignment: Important, but Only Half the Equation

The other half? Aligning and supporting downstream equipment. Here are best practices.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreCooling the Feed Throat and Screw: How Much Water Do You Need?

It’s one of the biggest quandaries in extrusion, as there is little or nothing published to give operators some guidance. So let’s try to shed some light on this trial-and-error process.

Read MoreSpecialty Purging Compounds Optimize Color and Material Changeovers

Selecting of the correct purging compound can speed up material and color changeover time and reduce scrap. You’ll even save on material.

Read MoreRead Next

Processor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read MoreAdvanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read More.jpg;width=70;height=70;mode=crop)