High-Temperature TPE Is Based on Silicone

Automotive engineers are becoming converts to thermoplastic elastomers as alternatives to thermoset rubbers, but they’ve found that TPEs can’t go everywhere rubber can—particularly under the hood.

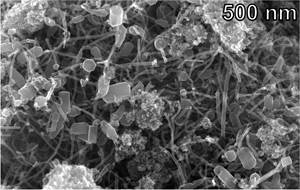

Automotive engineers are becoming converts to thermoplastic elastomers as alternatives to thermoset rubbers, but they’ve found that TPEs can’t go everywhere rubber can—particularly under the hood. For these applications, they need elastomeric thermoplastics that can survive long-term exposure to temperatures as high as 150 C (302 F) and ones that can take a combination of heat and contact with automotive fuels. To satisfy these needs, Dow Corning Corp., Midland, Mich., has come out with a family of TPEs based on vulcanized silicone rubber particles dispersed in a variety of engineering-thermoplastic matrixes. Dow Corning is a global leader in silanes and silicones, but its experience in thermoplastics to date has been only with silicone-based additives.

Dow Corning calls its new family TPSiV (thermoplastic silicone vulcanizate) and has sampled it to 30-40 selected customers in automotive and other industries. This pre-launch phase will last through the summer, during which time Dow Corning plans to sample 10-15 more customers. Kevin Murphy, portfolio leader for thermoplastics, expects to make TPSiV widely available in October.

At that time, the company will have captive capacity for making TPSiV through its acquisition in April of Multibase S.A. of France. Multibase compounds its own lines of TPEs. Dow Corning plans to produce TPSiV under the Multibase name in France and at Multibase’s U.S. operation in Copley, Ohio.

Not like other TPEs

The new family uses three different thermoplastic matrixes—nylon, polyester, and an unidentified proprietary resin. For the time being, company sources will not be more specific about these polymer vehicles for the dispersed silicone rubber phase. The nylon and polyester versions are said to have particularly good chemical resistance to automotive fluids. They also have a higher hardness range of 40 Shore D to 60D. Grades based on the unidentified vehicle are softer (40-50A to 60-70A) and have a silky, leather-like feel, which customers say is unlike that of other TPEs. They also show excellent resistance to automotive oils, glycols, and diesel fuels.

These materials can be injection and blow molded and extruded. (Predrying is necessary.) They are said to offer low compression and tensile set at elevated temperatures (in some cases, further improved by post-curing). Their broad colorability includes “appliance white,” which reportedly is difficult to achieve with other TPEs whose oils or plasticizers cause yellowing.

Dow Corning foresees applications in automotive tubing, air ducts, CVJ boots, and jackets for brake hoses and fuel lines. Other possibilities are wire and cable, chemical-resistant industrial tubing and conveyor belts, and seals and diaphragms. In addition, the TPSiV family is said to offer inherently good adhesion to a broad spectrum of engineering thermoplastics. Combined with their leather-like feel, that suggests premium soft-touch applications in areas like consumer electronics and cosmetics packaging.

For the most part, TPSiV will not compete with existing TPEs but with thermoset rubbers such as epichlorohydrin (ECO) types. Commercial pricing is expected to be in the range of $4.55 to $6.80/lb.

| New Silicone Vulcanizate TPEs | |||||

| TPSiV x1120 | TPSiV x1180 | TPSiV x2100 | TPSiV x3000-50A | TPSiV x3000-60A | |

| TP Matrix Processing Color Specif. Grav. Tes. Str., MPa Tens. Str., MPa @100% Strain Ult. Elong., % Flex. Modl, MPa Shore Hardness Tear Str., Die C N/mm Compress. Set, % 22 hr @23 C Brittle Temp., C Dielect. Str. @ 100 Hz, kV/mm Dielect. Const. @ 100 Hz | Nylon Injection Natural 1.11 31 25 182 254 59d 126 46 <-45 21.4 4.64 | Nylon Inj., Ext Black 1.09 24 19 207 319 52d 107 70 <-45 22.4 4.04 | Polyester Inj., Ext., Blow Nat. to White 1.173 13.2 10.9 201 231.5 46d 72.4 46.4 - 20 2.9 | Proprietary Injection Nat. to White 1.118 7.1 - 473 - 52a 23.5 13.7 - 19 4.37 | Proprietary Injection Nat. to White 1.206 13 - 814 - 62a 43.9 25.3 - - - |

Related Content

Research Suggests Path From Waste Plastics to High Value Composites

Flash joule heating could enable upcycling of waste plastic to carbon nanomaterials.

Read MoreRead Next

Understanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read More (2).jpg;maxWidth=970;quality=90)

(2).jpg;maxWidth=300;quality=90)

(1).jpg;maxWidth=970;quality=90)