How to Set Up & Maintain An Efficient Resin Handling System

In today's world, having a reliable resin-handling and conveying system is as important as having reliable electrical power.

Materials represent the single largest expense in most plastics processing facilities. In today’s world, having a reliable resin-handling and conveying system is as important as having reliable electrical power. Design, maintenance, and operation of the system can have everything to do with how well it meets production goals and objectives. Some systems can be quite big and complex, and it is always a good idea to get the advice of experienced system specialists. From design to installation to start-up and ongoing operation, their knowledge can help you avoid problems and get the most from your system.

The following hints and tips can help you get things right if you choose to design and install a system yourself, or they can help you prepare for a constructive conversation with a system supplier.

GETTING STARTED

First: Identify all of the materials that you process in your plant and where each material comes from. Refer to those silos, bins, and gaylord boxes as “sources.” Keep in mind that blenders and dryers may also be considered sources if loaders are pulling material from them.

Second: Make a complete list of every molding or extrusion machine in your plant and identify them as “destinations.” In this context, the hopper of a dryer or the material bins on a blender are considered destinations, since the system will be delivering material to them.

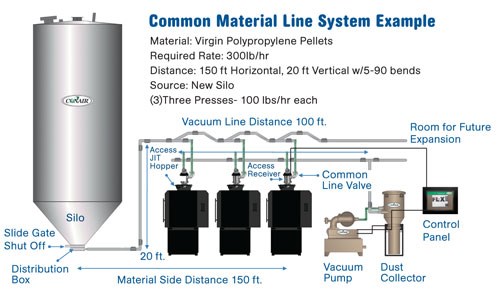

Third: Determine the maximum throughput rate (weight/hour) for each destination. The sum of these throughput rates, plus a factor for each 90° bend in the system and the horizontal and vertical distances that material must travel, will give you an indication of how large a vacuum pump will be needed and what diameter the conveying lines should be. Your equipment supplier can help perform these calculations and recommend the ideal pump(s) for your application.

In most cases, the line size will be dictated by the total throughput rate of all the machines served by that system pump. Remember to keep all the conveying lines served by a given pump the same size and make sure the line size matches properly with the horsepower of the pump. For instance, never put a large 15-hp pump on a small 2-in. OD line. The proper size for a 15-hp pump is 3 in. OD.

Rules of thumb for pump horsepower and line sizes:

- 5 hp = 1.75 or 2 in. OD line size.

- 7.5 hp = 2.25 or 2.5 in. OD.

- 10 hp = 2.5 in. OD.

- 15 hp = 3 in. OD.

- 25 hp = 4 in. OD.

Fourth: Pay attention to details. Vacuum-loader inlet tubes should match the system piping. Make sure existing loader voltages match up properly with the control system. Be sure the controller you choose has the features you need or that can be added in the future. It’s always much less costly to have features added at the factory rather than having technicians visit your plant to download new programs and add input and output cards.

Strategically locating the vacuum pump near the farthest machine from the source point will have the effect of balancing the system. A short vacuum line should have a long material line, and vice-versa (see illustration opposite).

DESIGNING THE SYSTEM

Keep material runs as straight as possible and minimize the number of elbows. Every change in direction in a material-handling system increases backpressure and reduces conveying capacity. A vacuum pump of a given size can do only so much work, and it is important to make sure as much of that work as possible goes into moving material instead of overcoming system design flaws. The expensive alternative is to install a larger pump, but remember larger pumps require larger line sizes, in most cases.

Optimize conveying velocity. When laying out your system and sizing your pumps, the designer will want to make sure the conveying velocity at the material pick-up point (gaylord, storage bin, or drying hopper) is as low as possible—preferably between 3700 and 4000 ft/min. Material will accelerate over the entire length of the run, and if it moves too fast, the material can degrade. Softer materials (like polyethylene) can heat up and smear against the walls of the conveying lines, deforming and leaving “angel hair” behind to clog the system. Brittle materials (like polystyrene or polycarbonate) can break up and create dust and fines that also clog the system. Abrasive materials (like glass-filled ABS) can wear away the inside of the conveying lines, eventually causing leaks and failures.

Make sure your vacuum pump is sized for your location. Power systems that operate at 50 Hz rather than the more conventional 60 Hz can cause the vacuum pump to turn more slowly, actually de-rating it by about 17%. You’ll need a bigger pump or one that turns at higher rpm in order to compensate. And don’t assume that a system specified for San Diego will operate the same way in Denver or Mexico City. Thinner air at high altitudes has the same effect as lower electrical frequency. Because the air is less dense, you need to move more of it in order to achieve the same conveying capacity as you would have closer to sea level. Again, you’ll need a bigger or faster pump.

If you are purchasing new loaders, an optional fill sensor in each loader can help avoid problems of overfilling or underfilling, which can occur when using only timer control. These devices can be invaluable in preventing equipment damage and keeping your conveying system running automatically.

MAINTENANCE

Keep your filters clean. Your material-handling system is equipped with filters at two locations: one in the dust collector near the vacuum pump and the others in each vacuum receiver. A blinded filter has the same effect as too many elbows in a system design: Backpressure builds and your system loses conveying capacity. As the filters clog, you’ll notice that it takes longer and longer to fill a vacuum receiver or, if the fill time is not changed, the receiver will not fill completely.

Locate and eliminate vacuum and material line leaks. Either one will diminish performance because the system will be sucking air rather than material. Again, you’ll notice sluggish conveying, longer fill times, and, in the case of a material line leak, you may see pellets on the floor. Leaks most often occur in flexible hoses and around couplings, seals, and valves. They can usually be located by visual inspection. Sometimes you can actually hear a hiss as air is pulled through a hole in the line. Smoke can also be used to locate a leak.

Pay attention to preventive maintenance on your vacuum pump. Follow the manufacturer’s recommendation for changing gear oil, and make sure all drive belts are tight and undamaged. Especially important, make sure the vacuum breaker valve is working properly. This valve is designed to break the system vacuum if it exceeds safe levels (about 15 in. of mercury) due to a clog in the line. If a dirty valve fails to open, a functioning breaker valve will keep the pump from overheating and damage.

OPERATION

Make sure your system is set up properly at the beginning. Have the manufacturer’s service technician check overall system integrity and see that all components are routed properly. All feed tubes should be properly set and receiver controls should be programmed with appropriate load and dump times.

Take care that the system always has material to convey. It sounds like a simple thing, but an empty gaylord or surge bin, or a feed tube that has become dislodged or clogged with a plastic box liner, will cause loader controls to alarm for lack of material. This can result in processing machine downtime and unscheduled maintenance. By making sure employees check material levels periodically, you can avoid costly production disruptions.

Train your operators. Especially when employee turnover levels are high, don’t forget to make sure everyone has the information they need to keep the system running. As noted above, a simple thing like allowing material to run out can be very disruptive. All employees should have a basic understanding of how the material-handling system operates and what their specific responsibilities are.

If you don’t have the resources in-house, a competent system manufacturer will usually be able to perform this training. Classroom training will cover how the system is set up and how material is transported. On the plant floor, employees can learn how to operate the various components, how to log into controls and make day-to-day adjustments, and how to change connections on a fantail manifold to source material from a different location or direct it to a different machine. Employees also need to understand various alarms and when a problem is simple (e.g., the feed wand fell out of a gaylord) or more complex, like an electrical issue that needs attention from an electrician or the supplier’s service technician.

Even small-scale material-handling systems can be complex, requiring careful calculation of throughput, conveying distances, equipment specifications, etc. Perhaps the most valuable tip of all is this: Take advantage of the knowledge, experience, and advice of your equipment supplier. With such help, you can avoid many of the common problems that can arise in the design, installation, operation, and maintenance of your material-handling system.

ABOUT THE AUTHOR

Doug Brewster is customer service manager of Conair in Cranberry Township, PA. He has almost 25 years’ experience with Conair. Contact: (724)584.5500; info@conairgroup.com

Related Content

How to Effectively Reduce Costs with Smart Auxiliaries Technology

As drying, blending and conveying technologies grow more sophisticated, they offer processors great opportunities to reduce cost through better energy efficiency, smaller equipment footprints, reduced scrap and quicker changeovers. Increased throughput and better utilization of primary processing equipment and manpower are the results.

Read MoreSingle View of Bin & Silo Material Levels in Multiple Locations

Got a bin in Buffalo and a silo in San José? BinMaster’s latest addition to its cloud inventory software lets you see all your resin inventory anywhere in one view.

Read MoreConair: Going All In on AI

A dozen new products debut at NPE, but the company says new AI-based conveying technology is the true game changer.

Read MoreConair: Going All In on AI

NPE2024: A dozen new products debut at NPE2024, but new AI-based conveying technology stands as the true game changer.

Read MoreRead Next

Delivering Increased Benefits to Greenhouse Films

Baystar's Borstar technology is helping customers deliver better, more reliable production methods to greenhouse agriculture.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More.jpg;maxWidth=970;quality=90)

.jpg;maxWidth=970;quality=90)