In today’s competitive world of manufacturing, it is more necessary than ever to use more efficient, and therefore sometimes complex, automation systems. The need for more automation has many sources. Here are some of the most obvious:

• Labor shortages. Low unemployment and more strict immigration rules have created a huge gap for all sectors of experienced labor. Skilled operators, process engineers and maintenance people are in short supply and create a need to improve efficiency, effectiveness and lights-out operations.

• Contamination issues. Many medical or high-end electronic products are very sensitive to contamination through human handling or do not allow contamination through particles (dust, liquids) or DNA.

• Part quality. Depending on the sensitivity of parts—due to delicate surface features, soft material, very thin sections, and critical dimensions—any uncontrolled interaction with humans can damage a part or decrease its quality. More human handling means more chances of quality defects.

• Productivity. Automation can often work faster, inspect faster, and occupy less floor space than manual operations. Automation systems also do not need break time or have performance fluctuations comparable to human operators. Most inspection through automation is measurable and much more repeatable and reliable.

• Overall efficiency. Since automation is best applied right at the molding machine, parts orientation is never lost and therefore need not to be regained by expensive bowl feeders or other feeding systems. Logistics are simplified by not having to ship parts to warehouses and back for further processing.

The point here is not to claim that humans perform “badly” in manufacturing processes, but rather to show that with the right knowledge, the right technology and the right preparation you can equip your plant personnel for higher tasks and make up for the lack of a qualified (and even unqualified) work force, as well as improve your production outputs, part quality, and overall efficiency at lower part cost. The rest of this article will address the different qualities of both the molder and hardware/software supplier that are needed to guarantee a successful automation project.

GETTING YOUR STAFF READY FOR AUTOMATION

How do you ensure that you have enough and qualified manpower to understand, operate and maintain highly complex automation systems?

Eliminate “firefighting.” One big challenge today is that after the economic crisis in 2008, many companies have radically reduced their maintenance staff and have outsourced their moldmaking or mold-maintenance operations. For many years, this did not seem to be a problem (especially in the first two years after the Great Recession hit, because business was down). After that, the effects still did not impact day-to-day operations drastically. Gradually, many companies came to accept the “firefighting” mode that resulted from these staff shortages as the normal status of operation. For operating a complex, high-speed automation system, this is a killer.

Don’t be scared. Implementing complex, high-speed automation at a molder that has experienced only pick-and-place or dropping parts out of the press is a scary and mostly unsuccessful approach. It is important that the molder contemplating an advanced automation project has been gradually exposed to automation from simple to more complex, and is therefore developing a solid automation process knowhow. Without this gradually buildup of skills, the best automation in the world would not be utilized to the best effect, since self-sufficient troubleshooting and process optimization is very difficult without those skills. Plant personnel should feel confident and motivated to work with the automation and not be scared of it.

See the value. It is important that not only the plant management see the value of automation, but even more so the people who will have to deal with it on a daily basis. This culture needs to be developed and does not just come by itself. Everybody must be involved in the project from the beginning and must understand the importance of getting everybody on the same page about expectations for this project and the performance of the automation.

Those last three points seem logical, but they are still the biggest reasons for an unsuccessful automation project on the Molder side.

Willingness of the team to grow and evolve. Highly complex automation is not something for everyone in the company. Usually, the employees who want to develop their skills and knowledge will grow with the project. In fact, these projects are a great way to expose the hidden talents in your employees. Find the talent and help them (and therefore yourself) to grow and evolve.

Early synchronization of the workcell partners. It is essential to align expectations and strategies between all project partners—molding machine, mold, and automation—early in the project. This must be done early in the project to utilize their different knowledge and skills to avoid mistakes and create an efficient work environment. Many times, the automation supplier can address obstacles in the mold that make automation difficult and vice versa. Eliminating those mistakes later costs extra money that was not approved in the budget and delays the time plan. Another drawback to avoid is the resulting poor climate of trust and cooperation, which does nothing to help the project’s progress.

Define clear interface responsibilities. Another important part of the project is to define clear interfaces between the team members (process responsibility, mechanical, electrical, software) so that everybody works together efficiently and their areas of responsibility in the project are clearly framed.

Clear URS (user requirement specifications). The URS is the heart of the project and defines the expectations of the molder. It is the molder’s strongest tool to address all requirements, concerns and limitations. Better make good use of it. It will allow all suppliers to provide a complete and reliable quote that addresses your requirements. For the suppliers, it is the guidebook to create the system. Therefore, the URS is very important and requires a decent amount of attention and detail. It will have a huge impact on whether timelines can be met and on the cooperative “climate” of the project.

WHAT’S REQUIRED OF YOUR AUTOMATION SUPPLIER

It is essential that the automation supplier have significant knowledge about the injection molding process, as well as injection molds and the quality defects typical for injection molding. The supplier should have knowledge about different plastic materials and their specific behaviors (MFI, soft vs. brittle, static charge behavior, surface sensitivity, tendency to show marks from silicone suction cups, etc.). If they do not have such knowledge, you will pay the price in delays, additional costs, and more.

In addition, it is important to know the machine-to-machine interfaces—SPI, electrical/Euromap 67, mechanical/Euromap 12, data protocols/Euromap 63 or 77—to name just a few.

Specialized in IMM automation. A knowledgeable supplier knows that the most important thing is keeping the cycle time as low as possible. The knowledgeable partner knows that his only chance to reduce the cycle time is to reduce the mold-open time. Reducing the cycle by 0.5 sec of mold-open time does not sound a lot. However, on a 5-sec overall cycle, it gives you 10% more output, which would translate to 570,000 more cycles (shots) per year. Multiplied by the number of cavities, let’s say 64, this would be roughly 36,800,000 parts more per year. Remember, we were only talking about 0.5 sec cycle-time reduction.

On the other side, the same knowledgeable supplier knows that once the mold is closed, the automation system movements should slow down enough that the robot returns to the mold only shortly before it opens again. The slower movements will significantly increase the lifetime of many components and therefore guarantee higher uptime. Use speed and high acceleration only where they are absolutely necessary.

Understands customer capabilities and weaknesses. This starts with proposing and designing reasonably complex automation fitting the customer’s capabilities. Some automation suppliers tend to “oversell” the molders with highly complex automation. This can overwhelm molders that will not be able to utilize the equipment to its maximum and maybe even end up frustrated and not utilizing the automation at all and afraid of automating further in the future.

As mentioned before, it is not only the molder’s responsibility to gradually build up its knowhow in automation and being able to operate and support it. Much more is it the responsibility of the supplier to understand the capabilities of the customer and therefore develop a customized solution that fits the available skills.

Next, it is essential to develop the automation concept with the customer involved. Bring the customer’s people on board—not just drop off the automation system at the customer. Have many review sessions so the customer has a chance to grow with the system while it is being developed and built. Thus, the customer has a chance early on to address its concerns and ask questions. In the end, the customer will get a system that is not unknown to him and he has some stake in it. He now is not only monetarily involved but also emotionally. Do not underestimate this part.

It is also beneficial to have a local supplier who understands the climate, culture, language and state or federal regulations like OSHA, MIOSH, UL, and any other challenges pertaining the country, region, or locality. This again can cost a lot of money if not understood and respected when building the equipment.

A good supplier knows and can support relevant industry-specific standards, including the validation standards—such as GAMP 5 (Good Automated Manufacturing Practice) for medical plants or FMEA (Failure Mode and Effects Analysis).

The supplier should know and use components and controls with good local support and acceptance. Sometimes the preferred control supplier or other components cannot be obtained. Usually these preferences are not a showstopper, but they can make things easier in terms of ease of operation and support for the customer.

Another important point is respecting and adapting to the customers production environment, such as climate, temperature, humidity and range of variability. Depending on the materials used and geometry of the part, temperature and humidity changes can dramatically change the electrostatic charge effect on parts. I have seen plastic parts fly off like a rocket or magically hover in a reject bin. This often cannot be simulated at the supplier’s factory acceptance testing because the environment there is completely different. The supplier must be prepared to assist the molder with efficient counter-measures. Nevertheless, it is even more important that the supplier make the molder understand that this point is the molder’s responsibility, since local conditions cannot be simulated or evaluated from the supplier’s side before the system is installed. But even then, the plant environment is a moving target that changes with the temperatures, humidity, material batches, etc.

Today, it is more important than ever before to understand cleanliness—cleanroom vs. white room vs. gray room or no restrictions. The automation supplier needs to know the different room specifications and the measures required to not jeopardize these limits. This could mean, for example, not using top-entry robots so as to avoid contaminating the molding area with particles from above. Or use special energy chains with reduced particle emission, or additional enclosures with laminar-flow boxes and HEPA filters. There are many more considerations: vacuum creation, compressed-air collection, exhaust-air filtering, etc.

The automation supplier should also be trained to understand the possible impacts on part quality due to batch-to-batch variations in materials (MFI–melt flow index) and other parameters, such as drying tolerances. This will help significantly in choosing the right methods and parameters for quality inspection.

An effective automation supplier today needs not only good telephone support, but advanced support technologies such as remote service solutions, web service support, and even augmented reality support.

It is a big benefit for a complex automation project to have a local project-management and support team, since reaction times are important. In the project phase, it is also beneficial to have significant overlapping work hours. If you are trying to coordinate a project with a European or Asian supplier in a time zone that is six to nine hours ahead or behind you, you may have zero to two overlapping work hours. Project coordination therefore becomes more difficult.

Offering a good local support, in terms of service technicians and spare parts inventory is likewise important. Remote services have helped significantly to reduce downtime and optimize equipment without a service visit. But there will always be a need for physical support at the customer side. Lack of local service support can result in significant downtime and can destroy a good yield with one incident if the system is down for multiple days or a week. Local service support cannot be completely replaced by remote services.

A good supplier of automation will always (when applicable) justify the investment with a solid ROI calculations.

AUTOMATION FEATURES TO LOOK FOR

Is it designed for most sufficient floor space usage? Medical and sensitive electrical and consumer parts are often manufactured in clean rooms or white or gray rooms. Those rooms are expensive and space is therefore limited. Using space efficiently can be a huge cost factor. That puts a premium on design of space-optimized automation systems. From supplier to supplier, there can be huge differences in layout concepts and space utilization. Consider this carefully before you place an order.

Is the design highly reliablefor high-speed, high-volume processes? A good automation manufacturer knows which hardware components are stressed the most in high-speed applications. The supplier also understands that it is not the speed that “kills” the equipment but more so the acceleration and the deceleration. The knowledgeable supplier will used oversized bearings and structural parts to stretch the maintenance cycle to the maximum as well as the lifetime of those parts. This extra cost is an investment in the reliability and effectiveness of the system.

Does it use latest materials that are light but robust? Investing in more expensive, advanced materials will, in many cases, pay off fast. Good and effective automation is not cheap but shows a reasonable ROI besides having great impact on quality improvement, reduction of contamination, overall cost reduction, and more.

Is it designed for low maintenance? Today’s technology offers components with low or no maintenance requirements. It is important to make intelligent use of those components to reduce downtime and increase yield. This also helps the molder to accept more complex automation. Oversizing certain components with limited lifetime, like bearings and structural parts, can make replacement less frequent.

Does it have good access points for troubleshooting and maintenance? One fundamental point that is often overlooked (or remembered too late in the design process) even by the best design engineers is to keep the automation simple to troubleshoot. This required that the operator have easy access to all sensitive areas where products can jam or that need readjustment after some time. All too often, these areas are buried under other mechanics or are just not readily accessible.

Is it designed for user-friendliness? Intuitive controls and HMI (Human Machine Interface) aid the acceptance of complex automation significantly. It is important that the supplier understand the skill level of the operators and adapt the control to the customer’s needs. In some production environments, it is essential to simplify the user interface and give limited access. In other environments, it is important to keep the interface as flexible as possible to allow the customer to dive deeper into the control and make changes himself.

Does it allow for fast and easy product changeover? For automation systems that can produce several different products and need changeover of certain components, like end-of-arm tooling EOAT), it is essential that changeover be fast and easy. Here quick-connects with integrated pneumatic, vacuum and electrical circuits are mandatory.

ABOUT THE AUTHOR Markus Klaus is president of newly established Hahn Plastics Automation, Inc. in Windsor, Conn. The firm represents Waldorf Technik, WEMO and GeKu, which are members of the Hahn Group in Germany and are experts in beside-the-press automation for injection molding. Klaus has worked in the plastic industry for 20 years at Wittmann Germany, Ferromatik Milacron Germany, Toyo Germany and Wittmann Battenfeld USA. Contact: (860) 977-9113; m.klaus@hahn.group; hahnplasticsautomation.com.

Related Content

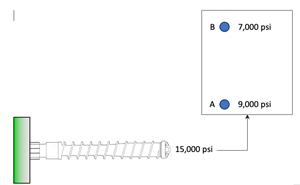

Understanding the Effect of Pressure Losses on Injection Molded Parts

The compressibility of plastics as a class of materials means the pressure punched into the machine control and the pressure the melt experiences at the end of fill within the mold will be very different. What does this difference mean for process consistency and part quality?

Read MoreMedical Tubing: Use Simulation to Troubleshoot, Optimize Processing & Dies

Extrusion simulations can be useful in anticipating issues and running “what-if” scenarios to size extruders and design dies for extrusion projects. It should be used at early stages of any project to avoid trial and error and remaking tooling.

Read MoreInjection Molding: Focus on these Seven Areas to Set a Preventive Maintenance Schedule

Performing fundamental maintenance inspections frequently assures press longevity and process stability. Here’s a checklist to help you stay on top of seven key systems.

Read MoreOptimizing Pack & Hold Times for Hot-Runner & Valve-Gated Molds

Using scientific procedures will help you put an end to all that time-consuming trial and error. Part 1 of 2.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More