How Backpressure Optimization Affects Melt Preparation

Backpressure is often the least understood of the settings in an injection molding process, even though it can play a significant role in the final quality of the part. Let’s start with understanding what backpressure is and then learn how to optimize it for a given mold.

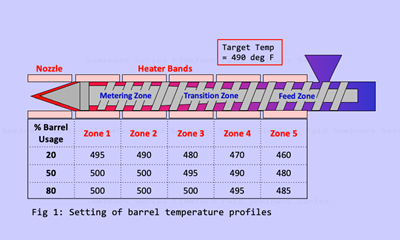

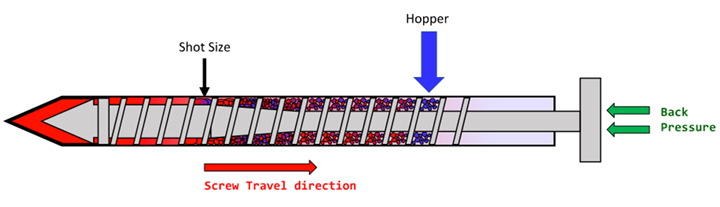

During the screw recovery process, the screw is turning to auger the plastic to the front of the screw tip. The plastic at the back is in the form of pellets, which melt as they travel forward. As we discussed in Part 1 of this series, the plastic melts because of radiant heat from the heater bands and shear heat from the turning screw. Backpressure is the pressure applied to the back of the screw during the screw recovery process.

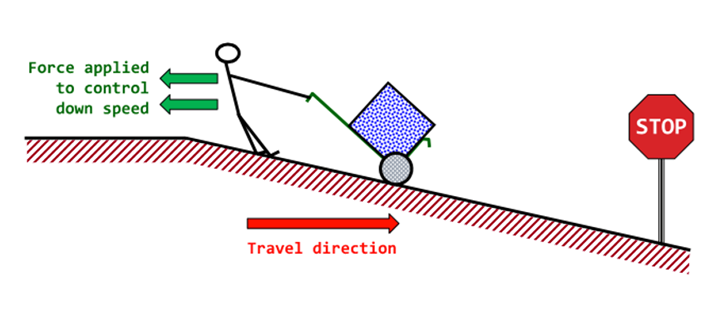

FIG 1 Force applied opposite to the direction of travel. (Images: Fimmtech)

Imagine going down an incline with a load, as shown in Fig. 1. One tends to put a force in the direction opposite to travel in order to control the speed of descent and accurately reach the stop position. If no such control was present, then the load would simply go crashing down the incline in an uncontrollable manner. Similarly, as the screw is turning to pick up the plastic, a small amount of pressure is applied to the back of the screw to return it in a controlled manner and consistently reach the correct shot-size position of the screw (Fig. 2). This dynamic is the first reason to apply backpressure.

FIG 2 Backpressure applied to the back of the screw during the recovery phase.

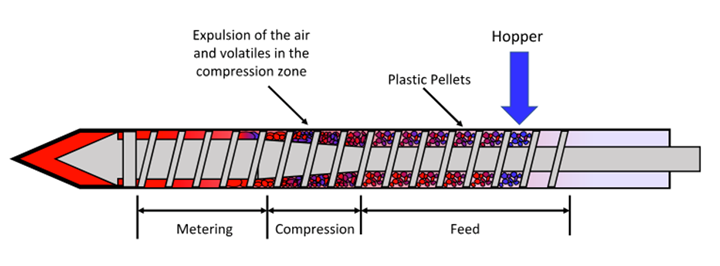

The screw consists of three zones: feed, compression (also called transition) and metering. The job of the transition zone is to compress the soft plastic pellets formed at the end of the feed zone and squeeze out all the air and any other volatiles that are present between the pellets and/or that may have formed during melting. The application of backpressure helps in this compression action and pushes the volatiles out. This is the reason why processors can often get rid of splay on a molded part by increasing the backpressure (Fig. 3). This is the second reason to apply backpressure.

FIG 3 The compression zone of the screw helps expel volatiles from the melt.

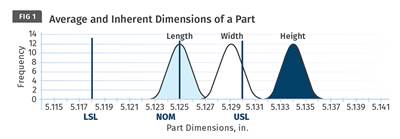

The goal of process development should be to achieve a robust process that will provide consistency from cavity to cavity, shot to shot and run to run. Consistency here would mean dimensional as well as cosmetic uniformity. Dimensional consistency translates to shrinkage consistency, which equates to having the same amount of molecules or weight of plastic in every shot. Since the shot size is fixed and assuming the cushion is not varying, the volume of the melt being injected into the mold is therefore fixed. Weight equals Volume multiplied by Density. This means that to get a repeatable shot weight, we need to have a repeatable melt density. The backpressure does the job of compressing the melt, and enough backpressure must be applied to achieve consistent melt density. This is the third reason to apply backpressure.

Study for Optimization of Backpressure

With this theory, understanding the study for backpressure optimization becomes simple. To test the consistency of the melt density, mold parts with no pack-and-hold phase. These are what are known as “Injection Only” or “Fill Only” shots where the screw moves from the shot size to the transfer position and no further. These are essentially parts molded only in the injection phase and should appear visibly short in most cases. Thick parts will show sinks.

Weight equals Volume multiplied by Density. This means that to get a repeatable shot weight, we need to have a repeatable melt density.

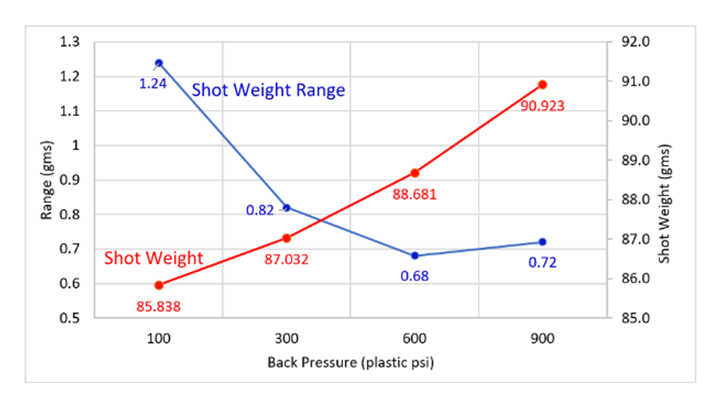

Next, weigh 10 shots, where a shot will comprise all the cavities and the runner. The consistency from shot weight to shot weight will reflect the consistency of the melt density from shot to shot. We calculate the range as the difference between the highest and the lowest shot weight and then plot a graph of range versus backpressure settings (Fig. 4). Select the backpressure where the calculated range is the lowest.

FIG 4 Weight range and shot weight as a function of backpressure.

There may be a range of backpressures where the calculated range is lower. This is actually good news since the backpressure can be adjusted as needed in this range. You will also notice that as the backpressure increases, the part weight also increases. This reflects the increase in melt density with backpressure. In this particular example, a choice of 600 psi of plastic pressure can be used for the backpressure. In fact, any pressure setting between 500 to 700 psi could work.

As discussed above, backpressure also helps squeeze the volatiles out of the melt. Once the backpressure is selected and the rest of the molding process has been optimized, if you still notice splay on the parts, backpressure may be increased to eliminate it fully. In such a case, increased backpressure is acceptable since it is important to get rid of the splay.

The process of optimizing screw speed (discussed in Part 1 of this article) and the backpressure study mentioned here can be time consuming. These studies are performed to optimize the melt quality, but part quality is not checked during these investigations. In other words, these are part-independent studies. Here is some food for thought. For a given material, is it possible to perform these studies on various screw sizes and then generate your own process sheet? Some research is being done in this area and initial results are showing a trend between machines and molds but not all the numbers match. This shows that there are other factors that need to be considered. In one of the future articles in this series, these results will be presented and discussed.

ABOUT THE AUTHOR: Suhas Kulkarni is the founder and president of Fimmtech, San Diego, an injection molding service-oriented firm focusing on Scientific Molding. Fimmtech has developed several custom tools that help molders develop robust processes, and its seminars have trained hundreds of individuals. Kulkarni is an author of the best-selling book, Robust Process Development and Scientific Molding, published by Hanser Publications. Contact: (760) 525–9053; suhas@fimmtech.com; fimmtech.com.

Related Content

Understanding Strain-Rate Sensitivity In Polymers

Material behavior is fundamentally determined by the equivalence of time and temperature. But that principle tends to be lost on processors and designers. Here’s some guidance.

Read MoreHow to Get Rid of Bubbles in Injection Molding

First find out if they are the result of trapped gas or a vacuum void. Then follow these steps to get rid of them.

Read MoreDensity & Molecular Weight in Polyethylene

This so-called 'commodity' material is actually quite complex, making selecting the right type a challenge.

Read MoreThe Strain Rate Effect

The rate of loading for a plastic material is a key component of how we perceive its performance.

Read MoreRead Next

Melt Preparation Part 1: Melt Temperature Optimization

A homogenous melt is required for consistent part quality, but achieving it requires balancing a number of factors, including barrel usage and temperature as well as screw speed, backpressure and residence time. Learn how to prepare your melt for molding success in this two-part series.

Read MoreImproving Molding Process Capability: Understanding the PVT Graph, Part 1

Process capability is related to the variation in part dimensions from shot to shot. High values of process capability require the shrinkage of the material to be identical on each shot, which can be confirmed from the pressure-volume-temperature (PVT) graph.

Read MoreVideo: Prepping Better Melt Preparers

The Molding 2022 conference concluded with a special half-day workshop and tour at the Polymers Center of Excellence.

Read More