Machinery & Robot Developments at Wittmann Battenfeld

Open house celebrates expanded U.S. headquarters & showcases innovations.

Some 200 visitors attended the open house at the expanded U.S. headquarters of Wittmann Battenfeld in Torrington, Conn., on June 5-6. The occasion was the official opening of a $3-million, 20,000-ft2 addition to the existing 70,000 ft2 , providing additional space for training, machine demonstrations, mold trials, warehousing, and machine modification and runoff (see June ’13 Starting Up). The two-day event featured nine operating injection molding cells, plus additional exhibits of robotics and auxiliaries, and a full slate of technical workshops presented by Wittmann Battenfeld experts as well as speakers from Fluid Automation, Gammaflux, MGS Mfg Group, M.R. Mold, and RJG Inc.

Among the highlights of the meeting, two speakers from the parent company in Austria noted

these developments in injection machinery:

• Expanding capacity: Michael Wittmann, general manager of Wittmann Group, said the company was increasing capacity for building EcoPower all-electric presses and for in-house manufacturing of giant 30-metric-ton platens for the company’s largest presses (1600 m.t.). The firm is also expanding its Mexican sales/service headquarters.

• More hybrids: Georg Tinschert, managing director and CEO of Wittmann Battenfeld, said the new MacroPower E hybrid two-platen line has been expanded since its introduction at last fall’s K 2013 show in Dusseldorf. The original 450-m.t. model is now accompanied by sizes of 400, 500, 550, 650, and 700 m.t.

• Thermoplastic composites: Tinschert also revealed that Wittmann Battenfeld is exploring with customers the nascent field of structural thermoplastic composites. In particular, he said the firm is looking into overmolding “dry” reinforcing fabrics, skipping the intermediate steps of purchasing and reheating preimpregnated “organic sheets,” as they are often called.

LOTS OF NEWS IN ROBOTS

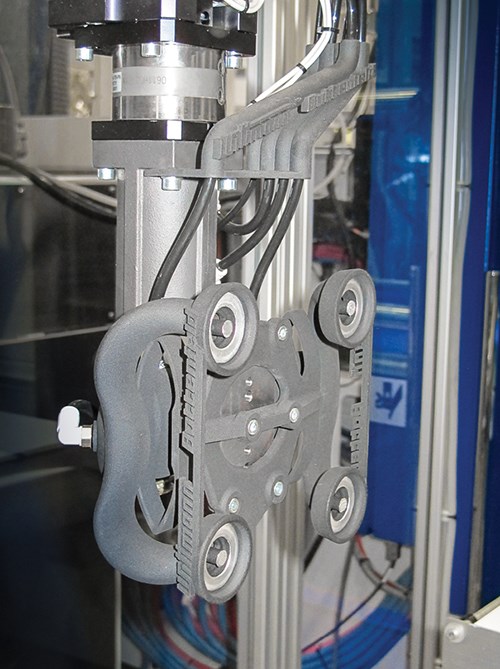

Wittmann Battenfeld showed off its newest robot line, the W8 pro series, which currently has just one model (W833 pro), which was introduced at K 2013. By October, it will be joined by three more models at the Fakuma show in Friedrichshafen, Germany. The line will eventually span the entire W8 series range from 6- to 275-lb payload capacity. The new series is said to be more energy-efficient, more vibration-resistant, and quieter than previous models and has a neater design with fewer and shorter cables and a more compact control cabinet, plus LED status lights like the latest versions of other Wittmann auxiliaries.

Duane Royce, v.p. of robots in the U.S., notes that the W8 pro series has a stiffer telescoping Y-axis, based on an aluminum profile, that is more stable and reduces shake. The carriage is also more robust, and the gearbox has been redesigned for longer life. The new drive system is not a general-purpose robot drive, but rather one tuned specifically for Wittmann models. Adding an optional servo wrist (A, B, C axes) requires just an additional inverter card, not an extra servo motor, which makes the wrist assembly more compact. And like other current Wittmann auxiliaries, the W8 pro robots have LED status lights that can be viewed at a distance: Green means OK; blue means “needs attention”; red means stopped.

There are several new software features for W8 and W8 pro series robots, including a new Wizard to make setup of pick-and-place tasks simpler and also more flexible than before. Instead of offering a choice of eight program templates, the Wizard now asks a series of questions, such as: Will the robot pick a runner or sprue? How many part placing positions are required (up to four)? Want a reject signal?

“No programming skills are required,” Royce says. “Video clips guide you all the way.” Answers to the questions are seamlessly integrated with Wittmann’s 30,000 program variations. The results are then presented in the existing QuickEdit program. A new setup overview screen is coming soon that will show all the selections made in the Wizard. When creating a new but similar job, the user can go back into the Wizard and change just the necessary parameters. Also new is a feature that lets experienced users jump through the setup

screens without following a set sequence.

Another new feature is Quickload access to stored job recipes without requiring password access, so anyone can load the operating program without waiting for a technician or supervisor. In the QuickEdit program, new filter views can show all setup parameters or just positions, speeds, times, vacuum levels, or counters.

Another feature to be released soon is One Touch Auto for onebutton launching of a reference routine and sending the robot to its ready position. If the robot is holding any parts, it drops them before heading to “home.” Also coming soon is Dry Cycle Direct in QuickEdit, another one-button command for a low-speed dry cycle. And a new Offline Editor allows a PC to emulate the teach pendant for remote programming.

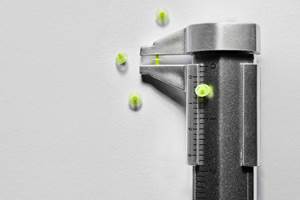

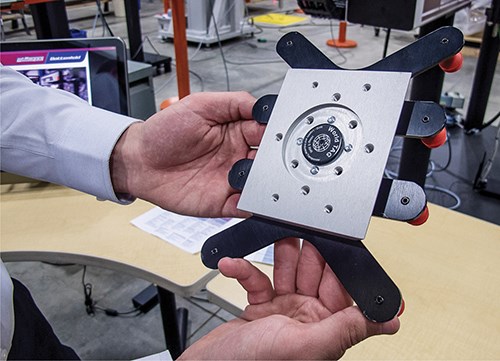

Meanwhile, the live exhibits demonstrated Wittmann’s first use of 3D printed robot end-of-arm tooling (EOAT), made of laser-sintered nylon powder for a four-cavity LSR mold. This demonstration project utilizes a new integral “leaf-spring” design in place of metal springs to provide

compliance for variations in part pickup position. Wittmann showed several other 3D

printed EOAT examples. Royce noted that printing allows integration into the EOAT of a

flexible bellows and air chamber, eliminating some formerly purchased pneumatic components. 3D printing is also said to eliminate machining operations that can account for one-third of EOAT cost.

Also demonstrated at the open house was Wittmann’s fairly new RFID chip technology, which is incorporated into both the robot EOAT and the robot arm. By communicating with the controller, it ensures that the proper tooling is loaded for a particular job.

Related Content

Finding a Niche in LSR Tooling

20 years ago, southern California moldmaker M.R. Mold & Engineering pivoted to LSR tooling, giving it a foothold in a challenging but growing market.

Read MoreBeacon MedTech Solutions Names New President

The Massachusetts-based medical molder and contract manufacturer has appointed industry veteran Jim Colony.

Read MoreLSR Molder Invests in Canadian Operation

Starlim is investing $10.4 million in its London, Ontario, LSR injection molding site, with plans to add 26 jobs.

Read MoreSlimmer All-Electric Press Debuts

A slimmed-down version of Engel’s all-electric, e-mac injection molding machine is among eight displays, which also include LSR micromolding, quick mold changes and a cube mold.

Read MoreRead Next

How Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreAdvanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read More

.png;maxWidth=300;quality=90)