New Approach to Micro Molding to Debut at K Show This Month

Close Up: Injection Molding

It has clamping and injection systems unlike any other machine on the market.

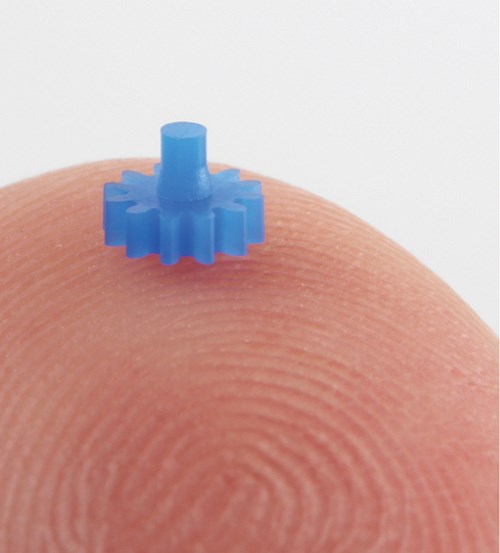

With both clamping and injection systems unlike any other machine on the market, the M3 High Volume Micro Molding Machine will make its first public appearance later this month at the K 2013 exhibition in Düsseldorf, Germany. This is the first complete molding system offered by MHS-Mold Hotrunner Solutions, Georgetown, Ont., a supplier of hot-runner systems. It is aimed at part weights below 50 mg and part volumes up to and exceeding 150 million parts/yr.

The machine is operated with a combination of electric servo motors and pneumatics. It is compact, measuring 1907 x 717 mm x 2300 mm high.

NOVEL TWO-STAGE INJECTION

The fundamental principle behind the design of this machine is minimizing melt residence time in order to preserve material quality, says Harald Schmidt, president of MHS. To that end, the M3 system is designed both for minimal melt inventory and also for the lowest practical melt temperature.

The injection system starts with a stationary (non-reciprocating) screw of 18 mm diam., the smallest that can accept standard pellets. (Larger screws could be supplied, if needed.) The screw operates on an intermittent basis, supplying melt to eight micro-plungers. These injectors are independently controlled and capable of up to 15,000 psi injection pressure. Each injector feeds directly into an MHS hot-runner valve-gate nozzle for direct gating into the mold cavity. These nozzles have 0.028-in., pneumatically actuated pins. Accumulation of the melt for each shot so very close to the gate avoids variations in shot volume that can arise from melt compressibility, Schmidt says.

Another unusual feature of this system, he points out, is that the plasticating screw delivers melt to the plunger injectors at a temperature below that normally required for filling a mold. That temperature is increased somewhat in the plunger, and increased further to final injection temperature in the hot-runner nozzle. This step-wise increase in melt temperature is the gentlest possible way of handling the melt so as to preserve maximum material properties while achieving good processability, Schmidt states.

MAGNETIC CLAMPING

The 4-ton clamp is perhaps the first to involve no pushing mechanism to force the platens together. Rather, the platens are pulled together by four electromagnets mounted in the corners. A linear electric motor accomplishes mold opening and closing. There are no tiebars, and the platens ride on rails. The ejector mechanism is built into the platens. Schmidt also notes that this clamp system allows for a large daylight opening of 18 in. and ample access from all sides to allow for in-cavity parts inspection and maintenance access.

MODULAR MOLD INSERTS

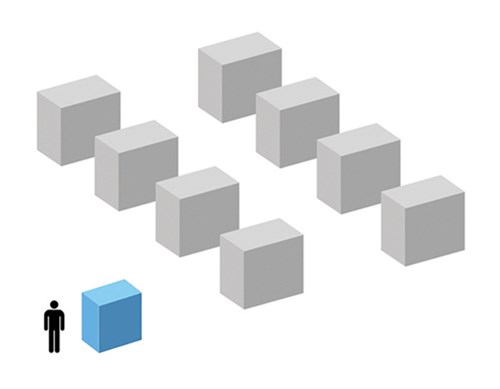

The platens serve as mold bases for four cavity inserts, each containing a row of eight micro-cavities. Those cavities are divided into two groups of four that can be two different part weights and shapes. That allows for molding eight different parts per cycle.

The M3 reportedly can mold 32 direct-gated parts with shot weights down to 5-10 mg every 5 sec with no waste. By adding small sub-runners to the inserts, it could be possible to mold 64 or 128 parts per cycle. Minimum cavity spacing is 18 mm. Another option is to convert the arrangement into two rows of 16 parts for a 2K overmold process with robot transfer between the first and second cycle.

Besides offering flexibility and costeffectiveness, this tooling concept allows for quick scale-up from prototype to production volumes, Schmidt says, because the process conditions would be identical for both. (Blank inserts could be used to run as few as four cavities for prototyping.) This provides a particular benefit for medical molders, because they could rely on the validation obtained for the prototype parts when scaling up to production volumes, he adds.

SELF-CONTAINED MOLDING CELL

The enclosed M3 system is designed for clean rooms. It has integrated automation—a linear arm that enters the mold area from above to demold parts by vacuum. It can also be configured to enter the mold from the side or bottom. This is convenient for reel-to-reel processes. Also, the cavity arrangement can be converted to two rows of 16 for a 2K overmolding process, with robot transfer between the first and second cycle.

Also included is an electronic camera to inspect parts while still in the cavities for quality checks. Inspection takes less than 1 sec for all 32 parts, even if there are eight different part designs.

The system also comes with dual touchscreens and a material loader.

Related Content

‘Monomaterial’ Trend in Packaging and Beyond Will Only Thrive

In terms of sustainability measures, monomaterial structures are already making good headway and will evolve even further.

Read MoreHow to Extrusion Blow Mold PHA/PLA Blends

You need to pay attention to the inherent characteristics of biopolymers PHA/PLA materials when setting process parameters to realize better and more consistent outcomes.

Read MoreSolve Four Common Problems in PET Stretch-Blow Molding

Here’s a quick guide to fixing four nettlesome problems in processing PET bottles.

Read MoreABC Technologies to Acquire Windsor Mold Group Technologies

The Tier One automotive supplier with compounding and blowmolding machine capabilities adds the 50-yr-old molder and moldmaker.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More