NPE Diary Vol. 2: The Show Opens and I Find a Machine Big Enough to Live In

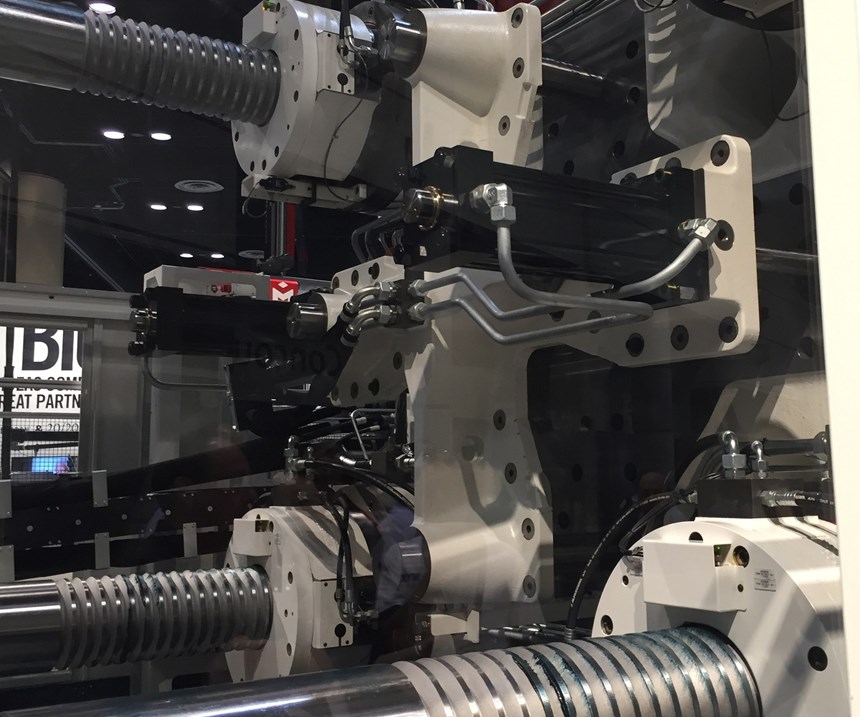

It’s hard to capture in one picture, but the Milacron Cincinnati machine is bigger than my apartment.

Now that NPE’s officially open (hooray!) I’m curious to see what gets buzzed about during the next few days, and looking forward to checking each buzzed-about item off my visit list. In 2015 I was always fascinated by the sky-scraping blow molding machines so I made plans to see those. I had also heard about an injection molding machine in the Milacron booth that was noteworthy simply for being really, really big. I told myself I’d see that at some point this week, but no rush. I figured it’d be hard to miss.

After the show opening in the South Hall, I wandered over to the West and ducked in for a quick peek. And there, right inside the door, was Milacron’s Cincinnati machine. I was right—it was hard to miss. If you’re looking for an injection molding machine that doubles as a second home, you should go find the Cincinnati.

I’m told that the machine is one of the biggest machines ever to live on the NPE show floor, if not the biggest ever. I had trouble imagining a bigger machine, frankly. It’s a monster. Seeing it operating in person is like watching Godzilla topple a city, but in real life (and also safer, and much more beneficial to society).

After spending a few dumbstruck moments, mouth agape, in front of the machine, I tried to find a dignified, eloquent way to ask someone a relatively silly question: “why is that thing so big?” I was awed by its size, sure, but I couldn’t really think of what would require an injection molding machine that’s large enough to double as a wedding venue.

A kind man in the booth gave me a very simple answer to my very silly question: big machines can make big things. As an example he pointed me toward a fully formed automotive dashboard panel that came out of the Cincinnati. Rather than having to mold multiple parts and put them together, the size of the machine enables big parts—like big containers, door panels and, of course, dashboards—to be made in one fell swoop.

There’s a clear economic benefit in eliminating a step in the manufacturing process. Instead of having to put a bunch of pieces together, you can just make one big, finished piece and go on from there. But beyond its size I just admire the simplicity of the solution.

I love learning about all the chemistry and all the complex thought processes that go into plastics manufacturing, and that go into making manufacturing more efficient. For example, I heard a speaker at the IHS event today discuss Industry 4.0 and about three minutes in I had to leave because my brain had exploded.

But the Cincinnati is a reminder that things don’t have to be complicated to be innovative or effective at solving a problem. Sometimes you just have to think big (literally).

In any case, more to come tomorrow. Hope everyone spent their first day as awestruck as I did.

~Jake

Related Content

Absolute Haitian Brings Next Generation of Presses to Orlando

Absolute Haitian says Generation 5 of the servo-hydraulic Haitian and electric Zhafir machines lines emphasize efficiency, performance and intelligence.

Read MoreInside the Florida Recycler Taking on NPE’s 100% Scrap Reuse Goal

Hundreds of tons of demonstration products will be created this week. Commercial Plastics Recycling strives to recycle ALL of it.

Read MoreAt NPE2024, Follow These Megatrends in Materials and Additives

Offerings range from recycled, biobased, biodegradable and monomaterial structures that enhance recyclability to additives that are more efficient, sustainable and safer to use.

Read More420 Stainless Steel Now Qualified With TrueShape 3D Printing Technology

NPE2024: Mantle's Additive Manufacturing Technology is Designed for Precision Tooling

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More