Plastics Processing Closes Best Quarter in Recorded History (Again)

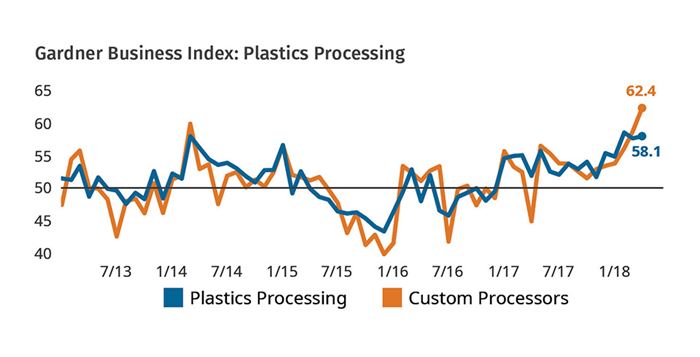

Overall index for April hits 58.1; custom processors climb to 62.4.

Registering 58.1 for April, the Gardner Business Index (GBI): Plastics Processing finished slightly above March’s 57.7 reading. Compared with the same month one-year ago, the index has increased by 11.1%, though it should be noted that the April 2017 reading was one of the lower readings recorded in that calendar year.

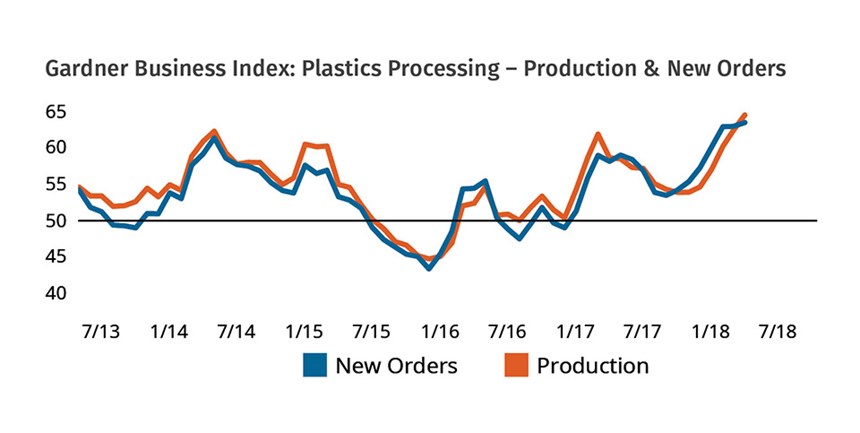

For the current month, the index was driven higher by production and new orders. Supplier deliveries, backlogs, employment and exports all pulled the averages-based index lower. All components of the index experienced growth during the month as exports again moved into expansionary territory.

Notable events in April’s data include strong expansionary readings for both production and new orders. Since the beginning of the year, the Plastics Processing Index has recorded four consecutive months of atypically robust growth in new orders. Simultaneously, production growth is currently at record-setting levels. The three-month moving average of production readings ending with April is higher than at any time in recorded history. The faster expansion of production relative to new orders may explain why backlog readings have been relatively tame by comparison.

Among only custom processors, the April index of 62.4 was its highest reading in history. Growth among custom processors has continually accelerated since October of 2017.

About the Author: Michael Guckes is the chief economist for Gardner Intelligence, a division of Gardner Business Media, Cincinnati. He has performed economic analysis, modeling, and forecasting work for nearly 20 years among a wide range of industries. He received his BA in political science and economics from Kenyon College and his MBA from Ohio State University. Contact: (513) 527-8800; mguckes@gardnerweb.com. Learn more about the Plastics Processing Index at gardnerintelligence.com.

Related Content

-

Plastics Processing Contracts Again

October’s reading marks four straight months of contraction.

-

Plastics Processing Business Index Contracts Further

All components dip as index hits low point of 2023.

-

Processing Activity Contracts More Slowly in January

Despite contracting again in January, plastics processing activity rebounded a bit from a rather significant drop in December.

.jpg;width=70;height=70;mode=crop)