Seeking Hot Niches for Special Films

When Ajedium Film Group’s (www.ajedium.com) extrusion machinery arrives this November, the Newark, Del., start-up company plans to make “film structures that don’t exist today, out of any resin that is melt processable at up to 800 F,” says Richard Giacco, majority owner.

When Ajedium Film Group’s (www.ajedium.com) extrusion machinery arrives this November, the Newark, Del., start-up company plans to make “film structures that don’t exist today, out of any resin that is melt processable at up to 800 F,” says Richard Giacco, majority owner. Giacco, a lawyer, and his father, Alexander Giacco, former CEO of Hercules Inc., Himont, and Montedison S.p.A ., like to invest in one-of-a-kind plastics businesses that have little competition.

In the early 1990s, they developed a small extrusion business, Race Plastics, to make high-clarity PP film. Their aim was to turn a commodity plastic into a specialty product. But then inexpensive imported OPP film arrived in the U.S., and overnight they were priced out of the market. So they closed the business and sold the extruders.

Later they invested in on-line rheometry, buying a stake in Rheometric Scientific Inc. of Piscataway, N.J., a developer of instrumentation to monitor melt during resin production.

The Giaccos also acquired technology from Air Products in the early ’90s and set up Empower Materials to polymerize the world’s only aliphatic polycarbonate, a super-soft, epoxide-based thermoplastic that costs about $100/lb. It’s used as a fugitive binder in ceramics and brazing because it burns off cleanly in sintering ovens, leaving only CO2 and water. As Empower’s sales leveled off with the slump in the electronics business, the Giaccos kept looking for new niches to exploit.

They researched the market for custom specialty, high-heat films and liked its prospects. They expect producers of high-heat resins to help drive demand by promoting new film applications. Ajedium’s role will be to develop actual products from specialty resins that have traditionally been injection molded. “Most resin companies don’t have the equipment or the expertise to develop these films themselves,” says Ajedium CEO Pete Woloson.

Ajedium’s initial idea was to make monolayer film in a wide range of resins, gauges, and widths. Davis-Standard Corp., Pawcatuck, Conn., designed a special extruder and screw to run an array of resins, with or without melt pumps or vacuum vents. Davis-Standard had built similar extruders for high-temperature plastics before, but only for resin companies’ R&D, not for production.

Davis-Standard came up with a special three-roll stack that uses synthetic oil as a heat-exchange medium. For thinner films, a rubber roll and water-cooled back-up rolls are used in place of one of the steel chill rolls. That’s because high-temperature film needs to cool slowly in order to avoid internal stresses that cause distortion.

An unexpected offer

Realizing that it was designing a production line with extraordinary R&D capabilities, Davis-Standard came up with an entrepreneurial idea of its own. It would give Ajedium coex capability—including a second extruder, two screws, a vacuum loader, and a special feedblock—all for the price of a monolayer line. In return, Davis-Standard wanted to be able to bring in customers to run trials for specified time periods a few times a year. It was an offer the Giaccos could hardly refuse.

Davis-Standard is now building the 2- and 2.5-in. extruders, both with 30:1 L/D. Cloeren Inc. in Orange, Texas, is building a coex feedblock for up to three layers and a flat die with automatic gauge control that will allow Ajedium to make film as thin as 1 mil. The line will be able to produce film rolls or cut sheets, and even to laminate in-line.

Ajedium’s multi-layer capability is believed to be a first for high-performance films. It will let Ajedium use specialty resins like PEEK cost-effectively. “We’ll be able to use a smaller amount of expensive resin and combine it with commodity resins,” says Kathie Cerchio, a director of Ajedium. Coextrusion will also let Ajedium incorporate costly regrind in a middle layer if product specifications allow.

Ajedium’s films will replace metal or other plastics in some cases, Cerchio says. “A customer might be using a pure polyimide or polyester film, even though it isn’t the best for what they want. We’ll give them more options.”

Ajedium will initially produce 48-in.-wide monolayer films. Its future products may target flexible circuits, chemical-tank liners, aircraft wire-insulation wrap, or decals and labels for high-temperature machinery.

Related Content

The Importance of Barrel Heat and Melt Temperature

Barrel temperature may impact melting in the case of very small extruders running very slowly. Otherwise, melting is mainly the result of shear heating of the polymer.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MoreAvoid Four Common Traps In Granulation

Today, more than ever, granulation is an important step in the total production process. Our expert explains a few of the many common traps to avoid when thinking about granulators

Read MoreThe Importance of Viscosity in Melting

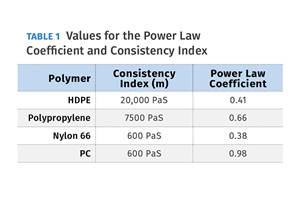

The calculations required to determine the right melt temperature for each polymer are complicated. Knowing the power-law coefficient and the consistency index of the polymer you run might prove useful.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreRecycling Partners Collaborate to Eliminate Production Scrap Waste at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair will seek to recover and recycle 100% of the parts produced at the show.

Read More