Sustainability, Innovation Intertwined at TC Transcontinental Packaging

Just 10 years in the plastics packaging business, TC Transcontinental has invested heavily to help its brand owner and retail customers meet their sustainability goals.

A family-controlled flexible packaging company that only 10 years ago entered the plastics packaging business is moving full throttle on developing more sustainable solutions for its brand owner customers.

TC Transcontinental was founded in 1976 in Quebec, Canada, by Rémi Marcoux and his two partners, who pooled their resources and bought a printing company that specialized in flyers. Throughout the 1980s and 1990s it continued to buy and turn around companies in the newspaper and magazine business. Its first foray into the U.S. came in 1986 when it bought a flyer business in Dayton, Ohio. Acquisitions of companies in the newspaper, book and printing business in Canada continued throughout the next two decades.

Through acquisition and organic growth, the company became a billion-dollar business in 1998. In 2000, it bought the company that published the iconic TV Guide. After that, it continued to purchase printing and publishing concerns. By virtue of a 2005 acquisition, in fact, TC Transcontinental became the first Canadian company to print The New York Times by securing a 10-year contract for Ontario and upstate New York.

Some 10 years ago, TC Transcontinental wanted to diversify and ventured into plastics when it bought the flexible packaging business of Schreiber Foods, which makes cheese and other dairy products, and formed TC Transcontinental Packaging.

The big buy came in 2018, when the company bought Coveris Americas, which immediately vaulted TC Transcontinental Packaging to one of the top 10 largest converters of flexible film packaging. That same year, it bought Multifilm Packaging Corp.’s high-end confectionary film packaging business.

By next year, TC Transcontinental Packaging will be running BOPE line on a line akin to this one. Photo Credit: TC Transcontinental Packaging/Brückner

You might think a relative newcomer to plastics packaging might be a step behind when it comes to developing and implementing strategies aimed at sustainability. Fact is, TC Transcontinental Packaging may be a step ahead. In 2019, just a year after its $1.32 billion purchase of Coveris, it became the first Canadian-based manufacturer to join the Ellen MacArthur Foundation’s New Plastics Economy Global Commitment. By 2025, the company pledges that 100% of its plastic packaging will be reusable, recyclable or compostable. Also in 2019, TC Transcontinental launched its vieVERTe line of sustainable products. That year as well, the business launched one of the first 100% recyclable, multilayer barrier stand-up pouches.

Today, the company is run by a second-generation family led by Isabelle Marcoux, who serves as executive chairman of the board. She has staffed the packaging business with industry veterans, including President and CEO Thomas Morin, who came from Amcor Flexibles; Alex Hayden, senior vice president, R&D, innovation, sustainability and ESG, another Amcor alum; and Nate Miranda, senior director of TC Transcontinental Packaging’s ASTRA (Art, Science, and Technology Research and Applications) Center in Menasha, Wisconsin. Miranda worked for Cryovac, the food-packing brand of Sealed Air, from 1992 to 2012.

The company has a strong position in a wide range of flexible films markets, including cheese and dairy, agricultural, pet food, beverage, snacks, household and consumer products, and more.

TC Transcontinental Packaging’s ASTRA center opened two years ago and has four state-of-the-art laboratories aimed at helping customers find sustainable packaging solutions. Photo Credit: TC Transcontinental Packaging

Inside ASTRA

The ASTRA Center, which opened in September 2021, has four different state-of-the-art R&D labs and a team of sustainability gurus headed by Miranda. “The idea was to have a facility where brand owners and retailers can benefit from a deep expertise in compostable, recyclable and recycled content packaging; increased speed to market from concept to commercialization; optimized solutions for performance and cost; and turnkey packaging solutions,” he says.

- At the Analytical and Testing Services Lab, physical testing is performed to simulate real-life use of the package from filling to transportation and distribution. Shelf life and consumer end use are also measured with analytical testing to develop molecular structures that meet the packaging functionality requirements throughout its entire life cycle.

- The Applications and Packaging Development Lab is home to a dedicated 9-layer blown film extrusion pilot line that enables designed experiments and optimization of film formulations. The lab also includes FFS machinery to make production-scale customer prototypes. This FFS testing is designed to gain insights on how films will perform, avoid any surprises on customers’ equipment, and ensure packaging performance and efficiency once the development stage is completed, Miranda says..

- The Advanced Compost Lab is reportedly the first of its kind within a packaging manufacturer. It is fully integrated with TC Transcontinental’s R&D team’s expertise and knowledge to develop the next generation of packaging and improve the turnaround time and cost for certifying compostable packaging. The lab is accredited (under independent auditing) to conform to ISO 17025 and is equipped to test and meet ASTM D6400 and D6868 standards for compostable packaging.

- The Recycling Technology Lab completes the company’s R&D suite of expertise with an in-house recyclability assessment lab. There, technicians have tools to help them determine if packaging containing non-PE components is detrimental or not to the PE film recycling stream, per the design guidelines developed by the Association of Plastics Recyclers. Lab equipment can also evaluate the quality of film produced from PCR. The lab includes equipment that turns film into pellets, an extruder with a strand pelletizer, a small blown film line, and an optical analyzer for counting gels in film.

Notes Hayden, “Things have shifted in the U.S. market. If you rewind maybe 10 years, the focus of many customers was on cost, and sustainability was not really on the radar. Today, though, every customer conversation is about sustainable packaging. Even when the conversations get to our CEO and the CEO of our customers, sustainability is critical. So that’s front and center for us, and that’s our key priority — growing organically and profitably means we grow through sustainability.”

The nine-layer line, purchased from a resin company, was high on Hayden’s agenda when plans for the ASTRA Center were formulated. “We’ve just got to be more nimble, more agile. We needed a pilot line, invest in equipment where we can turn over customer samples faster.”

Nine-layer pilot film line at the ASTRA Center helps TC Transcontinental Packaging quickly develop structures for customers to evaluate.

Miranda adds, “Our customers generally fall into two categories: some are very sophisticated. They understand EPR (extended producer responsibility) packaging laws that are coming. They understand what’s been done in Canada, what’s been done in Europe and they understand what’s evolving in the U.S. And then, on the other end of the spectrum, there are customers that don’t really understand what’s happening, what legislation could be coming. They ask us, ‘What should I be doing?’ In either case, we’ve invested in the right talent and tools at the ASTRA Center that allow us to meet customers where they are and provide them with the support they need to reach their sustainability goals.”

“Today, even when the conversations get to our CEO and the CEO of our customers, sustainability is critical.”

Hayden adds, “What it boils down to is that the customer is focused on end-of-life. ‘How do I make my package recyclable or how do I include PCR? Are compostable solutions right for me? We want to include 10% PCR by weight into our plastic packaging and we want to redesign all of our plastic packaging to be recyclable or reusable. The idea behind the ASTRA Center is to address all those concerns.”

Hayden notes that results of the investment TC Transcontinental Packaging has made in the ASTRA Center are evident in the evolution of the company’s sustainable product line. This includes its recycle-ready Integritite PCR collation bundling films, which are available with up to 50% PCR.

Monomaterial Solution

And, more recently, consistent with a move toward monomaterial packaging solutions, TC Transcontinental Packaging invested $60 million in a Brückner biaxially oriented PE line, the first such line ever installed in North America, and the associated expansion of its plant in Spartanburg, South Carolina. The line is expected to be up and running some time next year.

“We’ve been making serious investments in making products more sustainable. We’ve invested in our R&D talent, in the ASTRA Center, and have acquired new assets such as our first-of-its-kind BOPE line. This is an exciting time to be in flexible packaging, and I think, and in fact I hope, other companies are following a similar trajectory.”

Related Content

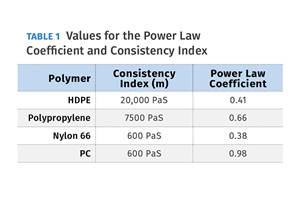

The Importance of Viscosity in Melting

The calculations required to determine the right melt temperature for each polymer are complicated. Knowing the power-law coefficient and the consistency index of the polymer you run might prove useful.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreCooling the Feed Throat and Screw: How Much Water Do You Need?

It’s one of the biggest quandaries in extrusion, as there is little or nothing published to give operators some guidance. So let’s try to shed some light on this trial-and-error process.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MoreRead Next

Processor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read More