System Moves Color Control From Lab to Production Floor

In-line spectrophotometer from Equitech promises to move color management out of the lab and right to the extrusion line to slash waste and improve quality.

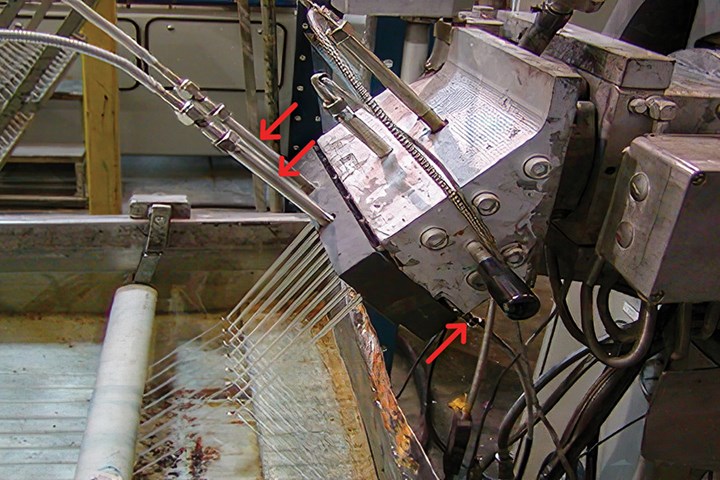

Equitech International Corp., Mullica Hill, N.J., is advancing technology that will reportedly allow processors to measure and control color right at the source—the extrusion line. Called the Inline Process Spectrophotometer (IPS), the system relies on an inline ultraviolet-visible spectrophotometer equipped with rugged fiber-optic probes installed directly in the melt stream, making it unnecessary for operators to trek samples to the lab to correct off-spec product after hundreds of pounds have already been made.

“As Industry 4.0 moves production facilities towards increased computer control, there is a need for inline, real-time measurements to enable improved product quality and consistency,” notes Dr. Jaime Gomez, Equitech president and CEO. “Ideally, a process-measurement system will provide data on product-quality indicators that can be used for immediate and automatic adjustment of process parameters to maintain the highest product quality without having to wait for a sample analysis to come back from the plant’s laboratory.”

Equitech has been in business since 1995, starting with supplying fiber-optic spectroscopic instruments for process analysis to pharmaceutical, chemical and food manufacturers. It entered the plastics market around 2005 with the introduction of the Equispec inline color-monitoring system. This is Gomez’s second go-round with the firm. He returned in 2019 and initiated an effort to extend the technology beyond inline color monitoring to real-time closed-loop process control.

“Everything about this technology has improved over the past 20 years,” says Gomez. “The stability, repeatability and reproducibility of the instrument has improved significantly, thanks to the knowledge acquired over the years about the handling of fiber optics, production of the spectrometer, advances in electronics and communications, etc. Equitech’s current technology is third-generation. We will be deploying generation four later this year and generation five in 2022. Each generation instrument brings more capabilities. Gen V will bring a totally new software interface.”

Gomez is joined at Equitech by polymer industry veteran Dr. Joseph Golba, v.p. of innovation and implementation; and Dr. Jonathan Babaie, dir. of technology, who has a background in electrical and optical engineering.

Says Golba, “The typical delay in receiving laboratory results can mean that hundreds to thousands of pounds of off-specification material can be produced before the operator is aware of the quality issue. This increases production costs, forces segregation of bad product, and creates a waste-disposal problem for the plant.”

How it Works

Gomez says Equitech’s technology can be used in virtually all plastics processes but fits best in extrusion. Target applications include color compounding, though the firm also has inline color-measurement systems in place at various profile extrusion operations.

Gomez says, “In extrusion, measurements of temperature and pressure are commonplace. Screw speed and feed rates of materials are set and monitored. The missing piece of information is inline measurement of product quality. Ultraviolet-visible (UV-vis) spectroscopy is an excellent method for obtaining this information. It’s been shown that this instrument, by measuring the product color, can sense changes in material feed rates, screw wear, product degradation due to temperature excursions, and variations in raw materials.”

As Babaie explains, the IPS works as follows:

• Illumination light is produced by a light source

(for example, a xenon flash lamp) and carried via fiber optics to process probe.

• The light interacts with sample (reflection or transmission).

• Detection light is carried back to the spectrometer via fiber optics.

• Spectrometer converts light signal (spectra) into electronic signal.

• Electronic signal calculates color-measurement values (L*a*b* being most popular).

• The procedure repeats every 1 to 30 sec.

The company has different melt probes for clear or translucent melts. The Reflection Polymer Melt Probe used in the IPS was invented by Equitech and, according to Gomez, has been perfected over the years based on actual usage in the field.

Probes are placed in the die head through a standard ½-20 UNF port that is typically used for temperature or pressure transducers. The probes’ sapphire windows can withstand up to 370 C (700 F) and 5000 psi. Materials in contact with the process are the sapphire window and Hastelloy probe tip.

Three Tiers

The technology is available in three iterations. In alarm mode—the simplest, easiest and least expensive option to implement—the instrument is used to detect and activate an alarm when any color or compositional feature (e.g., stabilizer additive) drifts out of specification. It is then up to the operator to identify the source of the deviation and act appropriately.

This could be what Golba calls a “simple, short-term perturbation” that is easily identified and can be “adjusted out” while the production proceeds. So, for example, If the out-of-specification material is of very small quantity, it can be diluted with in-spec material. “Or it may be a more serious issue that requires analysis and a longer time to fix,” Golba elaborates. “In this case the out-of-spec material can be diverted, thereby preserving good material, while the issue is identified and corrected. For really serious issues, production can be stopped while the issue is identified, and corrective actions taken.”

In either case, out-of-spec production material is minimized and is largely prevented from contaminating “good” production material, thereby reducing waste, says Golba.

Tier 2 offers processors what Equitech calls real-time quality assurance (QA). In combination with the Tier 1 alarm system, the instrument is used to monitor a color or compositional feature inline and in real time to ensure the quality of the product continuously over the entire production run. “This works when a color or compositional feature is critical to the customer,” says Golba. “It can also be used to ensure that required levels of stabilizers are maintained throughout the production run. With real-time QA the customer is guaranteed that virtually every kilogram of the product is within that critical specification.”

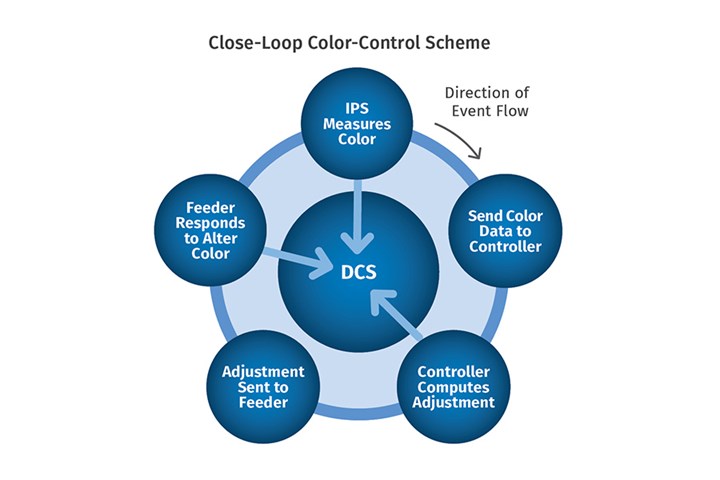

Gomez says while the alarming and QA functionality have been useful for plant personnel, a newly developed Tier 3 setup extends plant automation to a new level: real-time closed-loop control. He notes, “Combining the capabilities of the Tiers 1 and 2 and the utilization of appropriate control algorithms, the ability to monitor and control the quality of the product being produced in terms of its color and/or compositional features over the entire production run can be realized.”

Closed-loop control works when the dosing of compositional constituents responsible for color (or other features, such as chemical stabilizers) can be independently controlled in real time (i.e., with independent feeders). It requires software that interfaces with feeder and extruder control systems and integration of the instrument system with the control system of the extrusion line, and perhaps the intra-plant communication network, Golba notes. He adds, “Implementation of closed-loop product control of compositional constituents guarantees the highest levels of quality, lowest rates of waste generation, highest level of productivity, and lowest cost to manufacture quality goods.”

But as Equitech notes, implementing true closed-loop control is challenging in extrusion. “The extrusion equipment market is highly fragmented and there are many different vendors of extruders and feeders for dosing additives, including the pigments used to color plastics,” Gomez elaborates. “Extruders may be single-screw, twin-screw, or multi-screw and come in output capacities ranging from a few pounds per hour to tons of material per hour. Feeders may be gravimetric or volumetric and allow for multiple colorants to be dosed into the extruder for a specified recipe.”

At the heart of IPS closed-loop system is a Distributed Control System (DSC). This computerized control is used in a process or a plant and helps automate the manufacturing process.

At the heart of IPS closed-loop system is a Distributed Control System (DSC). This computerized control is used in a process or a plant and helps automate the manufacturing process. Gomez adds, “Likewise, there are multiple vendors of plant-control software packages to which data and results will need to be communicated. It is expected that no two manufacturing sites will handle process data in exactly the same way, so flexibility in the communications capabilities of software will be vital.”

As Babaie explains it, in the Tier 3 setup, multi-dimensional data is collected by the instrument. Each spectrum consists of several hundred individual wavelengths and responses. Color is calculated from a spectrum by well-established equations and can be thought of as existing in a three-dimensional “color space.” One axis, denoted by L*, gives the white-black character of a color. A second axis, denoted by a*, gives the red-green character of a color. The third axis, denoted by b*, gives the yellow-blue character of a color.

Related Content

DSM Launches an AI Powered Color & Mechanical Properties Prediction Tool

Called Lucidiris, this prediction tool can reduce time to market when developing colors of high-performance materials for a variety of applications.

Read MoreUnderstanding the ‘Science’ of Color

And as with all sciences, there are fundamentals that must be considered to do color right. Here’s a helpful start.

Read MoreGet Color Changes Right In Extrusion Blow Molding

Follow these best practices to minimize loss of time, material and labor during color changes in molding containers from bottles to jerrycans. The authors explore what this means for each step of the process, from raw-material infeed to handling and reprocessing tails and trim.

Read MoreSPE’s Automotive Division Names 2022 Hall of Fame Winner

First mold-in color weatherable grille used on the 1987 VW Golf to be celebrated at the 51st annual SPE Automotive Innovation Awards Competition & Gala.

Read MoreRead Next

Five Effective Ways to Control Color

A 50-year veteran in color-concentrate production and use shares practices to help you make better color decisions and generate less scrap. To specify color correctly and communicate your specs to your color supplier requires understanding of the “Five U’s.”

Read MoreAvoid These Three Mistakes to Get the Most from Color

Here are the key misconceptions and common practices that keep processors from reaching the heights of coloring proficiency. Find out if you’re stumbling into these pitfalls, and learn how and why you should swerve around them

Read MoreUnderstanding the ‘Science’ of Color

And as with all sciences, there are fundamentals that must be considered to do color right. Here’s a helpful start.

Read More.png;maxWidth=970;quality=90)