Bioplastics Family Gets Increasing Play in Luxury Cosmetics Applications

Finland’s Sulapac eco-startup founded by two female biochemists specializing in biomaterials has been steadily making inroads with companies like Chanel.

Sulapac, a Finnish eco-startup company that first came to our attention in 2019, appears to be making significant strides with its biobased products, particularly in the luxury cosmetics packaging arena. One example is Sulapac’s evolving ‘partnership’ with Chanel. This leading brand was among Sulapac’s early investors. Sulapac was founded by two female biochemists specializing in biomaterials--Suvi Haimi and Laura Tirkkonen-Rajasalo. They recently provides us with some further clarification on their Sulapac materials.

Sulapac materials are made of responsibly sourced plant-based biopolymers and sustainable fillers like wood chips from industrial side-streams. According to the co-founders, the beautiful, natural appearance is based on unique combination of raw materials. Says Haimi, “Our wood originates always from certified forests. We follow our strict policy for sustainable sourcing. “

The matrix resin varies between recipes and the recipe is always a unique combination of responsibly sourced biobased and biodegradable biopolymers and sustainable fillers. The biobased content in each recipe is maximized.

In early 2021, Sulapac launched a barrier for water-based cosmetics that biodegrades without leaving permanent microplastics behind. This has never been done before, says Haimi. “Our innovation is a perfect fit for cosmetic brands and sets a new standard when comparing biodegradable materials to conventional plastics. Cosmetic packaging acceptable weight loss for emulsions is typically less than 3%. Sulapac barrier clearly meets this requirement as the weight loss is significantly below the target value.”

Says Haimi, “Sulapac’s business model is based on partnerships and factor in as a service concept, meaning we do not own any production facilities but partner with existing production plants. This business model enables localized manufacturing of the end-products, and as our business grows, also the material production can be taken close to the customer.”

According to the co-founders, Sulapac granules can be used on existing converting lines to replace conventional plastics, such as PP. Sulapac materials can be processed with traditional plastic product machinery and technologies, including injection molding and extrusion. As such, no big investments are needed, only some minor adjustments of the existing equipment, tooling, and processes are required.

In addition to the barrier material, Sulapac offers these customizable materials:

▪ Universal material--designed to fit to existing production lines and molds. It is suitable for rigid products such as jars, hangers and cutlery.

▪ Universal Flex 35--designed for sustainable thin-walled structures that have good impact strength. It boasts excellent flexibility and is food-contact approved for dry food.

▪ Sulapac Premium—said to make products look and feel luxurious. The ceramic sound and visible wood chips’ haptic touch make it stand out. It is ideal for sustainable products that aim for an exclusive feel. The material is processable with existing injection molding machinery. Sulapac experts assist with the tests and production settings from mold selection to nozzle size.

▪ Sulapac Premium Flex 40 –also said to make products look and feel luxurious, this is a grade with more flexibility and better impact strength than Sulapac Premium. The visible wood chips’ haptic touch make it stand out. It is ideal for exclusive sustainable products that aim for that exclusive feel. It is also processable with existing injection molding machinery and Sulapac pros assist with the tests and production settings from mold selection to nozzle size.

The Chanel Connection

In 2018, Chanel launched a new olfactory world to the fragrances of the House of Chanel: a singular collection, inspired by Mademoiselle Coco Chanel’s favorite places, fueled by the imaginary and composed around freshness. Les Eaux De Chanel was conceived with sustainability in mind. Its glass perfume bottles are thinner and lighter, which means a smaller volume of raw materials and optimized transport, and the corrugated cardboard that is normally hidden was transformed into clean, simple outer packaging whose lack of lamination or glossy coating makes it easier to recycle.

Since 2021, all of the 125 ml bottles in Les Eaux Dd Chanel collection are topped with a biobased cap, which Chanel developed in partnership with Sulapac. For two years, Chanel teams worked hand-in-hand with the Finnish startup to create an unprecedented cap composed of three layers, made out of 91% biobased materials obtained from renewable resources and FSC certified wood chips (by-products of industrial side-streams).

More recently, the expanded ‘partnership’ has resulted in a range of beauty innovations from Chanel with sustainable Sulapac materials.

For the first time, the new packaging material includes camellia seed shells. This technical challenge in product design took over 40 trials to perfect, resulting in several international patents pending.

The full range of packaging for the N° 1 de Chanel Cream is eco-designed and includes 90% biobased materials from renewable resources. Faithful to the House of Chanel’s exacting standards, every detail was considered at length including the sensory quality of the material; its resistance to heat variations; the unique sound of the jar closing; how it feels in the hand; and the depth of the matte satin finish engraved with the iconic double C.

It took more than 40 trials before Sulapac’s R&D manager, Piia Peltola was able to find the right material recipe. “It has been fascinating to see up-close this level of devotion to the brand feel and its environmental impact. Our first big task was to innovate a biobased material that contains by-product camellia seed shells whilst making it resistant to heat and moisture. It was just a concept idea when we started. Camellia is inherently hydrophilic material, meaning it absorbs water strongly. Solving this was a great accomplishment from us, and the first time we have incorporated such ingredient in our packaging material in a bespoke way.”

Says Haimi, “By this example we encourage more companies to choose sustainable packaging materials. It was fascinating to combine byproducts like camellia seed shells and FSC certified wood chips in this unique packaging material. Now, we have proficiency in also utilizing other side streams without compromising the functionality of the final product. It helps us to reduce the environmental footprint even further.”

Related Content

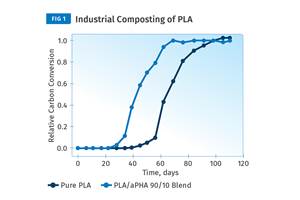

Why Are They Blending Biopolymers?

A sit-down with bioplastic producer Danimer Scientific showed me there are more possible answers to that question than I had previously thought.

Read MoreHonda Now Exploring UBQ’s Biobased Material Made from Unsorted Household Waste

UBQ is aiming to expand its reach for more sustainable automotive parts as well as non-automotive applications.

Read MoreCling Wrap Made from Potato Waste

Australia’s Great Wrap to expand into U.S. with home compostable cling wrap and its refillable dispenser made from recycled PET bottles.

Read MoreBlend Amorphous PHA with PLA to Improve injection Molded Part Properties

Adding aPHA to PLA can boost a range of mechanical properties and expedite composting. Here are the details as well as processing guidelines for injection molding the blends.

Read MoreRead Next

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More (2).jpg;maxWidth=970;quality=90)