Look Mom, No Operator: AGVs Invade Chinaplas

Automated guided vehicles (AGV) featured prominently at Chinaplas 2016 indicative of that country’s embrace of higher technologies and its need to offset ever-increasing labor costs.

Automated guided vehicles (AGV) featured prominently at Chinaplas 2016 indicative of that country’s embrace of higher technologies and its need to offset ever-increasing labor costs.

Automation was everywhere at Chinaplas 2016, from robots on virtually every molding machine to a special automation zone to the word itself, printed repeatedly on official show signage, along with “innovation” and “green solutions”. Beyond a branding exercise or more rudimentary pick-and-place systems, however, two suppliers made unattended self-driven AGVs a prominent part of their show display.

AGVs are not new, with factories running unmanned forklifts along guidewires as early as the 1950s, but the concept and the need are relatively novel in China. Stanley Chu, chairman of Chinaplas organizer, Adsale, acknowledged his country’s burgeoning need for robotics at his pre-show press conference. Flanked by Ada Leung, Adsale’s general manager of sales and marketing, Chu took questions from a dais in front of a red back drop where “automation”, “innovation”, and “green solutions” were printed again and again in white, emphasizing the importance of robots even if he hadn’t.

“China will no longer be a low-production-cost country,” Chu said. “Production costs are going higher, labor costs are going higher, and the country faces all these restrictions on further economic growth. That’s why we have to focus more on automation and high technology and high productivity. We can’t just rely on the low cost of labor and the low cost of land.”

While still low compared to developed economies, China’s wages have increased dramatically over the last 15 years. According to the Bureau of Labor Statistics hourly compensation costs in China’s manufacturing sector nearly tripled from 2002 and 2009, jumping from the dollar equivalent of $0.60/hr to about $1.70/hr, and rising more since then. The Conference Board estimated that China’s hourly compensation rate in dollars for manufacturing workers was $3.07 in 2012. According to the China Labour Bulletin, there has been near double-digit growth in the national average annual wage for urban employees since 2004, with it reaching 56,339 yuan in 2014 (around $9,000).

China has already responded with world-leading investment in automation. In 2015, when global sales of industrial robots reached record levels for the third year in a row as they increased 8% to almost 240,000 units, China had highest demand, with sales of industrial robots there climbing 16%, according to International Federation of Robotics (IFR). The IFR report called China the main driver of growth, globally, for automation, with the country claiming 66,000 or nearly 30% of total global industrial robot sales.

Leung noted this investment but also said it needs to continue. “We talk about Industry 4.0, and a lot of people believe that China’s automation level is at 2.0,” Leung said. “We have to go to 3.0, which would be full automation, and then get to 4.0 which is smart automation.”

Smart Automation

At Chinaplas, “smart automation” was on hand at the booth of injection molding machine supplier Borche and auxiliary equipment supplier Shini. Both companies featured AGVs roaming their booths unattended, shuttling boxes meant to represent production output in a molding plant.

Shini showcased its SCIG (collective storage system) paired with an AGV. The display was meant as a mockup of delivering products from the molding machine to the warehouse, with a Shini high-speed ST3-900-1600HT pulling parts from a static press and stacking them on the SCIG. The SCIG then collected full pallets and conveyed them to the AGV, which after receiving them, transported the pallets to a faux warehouse, according to Grace Lee, of Shini’s automation business department. At this time, Lee said Shini doesn’t have any of the full systems installed but said the show and the display had generated “many inquiries.”

For its part, Borche mocked up a similar display, with an AGV moving between molding machines in live production. Automation is an accepted reality wherever you’re located. In Plastics Technology’s 2015 World-Class Processor survey (you can take the 2016 survey here), 77% of our top performers reported using automation of some sort, with fully 100% using sprue pickers. As work that once came to China from the west now leaves its borders for lower-cost locales in Southeast Asia, expect to see continued investments in automation in China.

Related Content

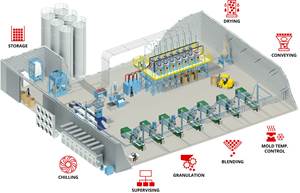

A Cost Saving Modular Approach to Resin Drying Automation

Whether implementing a moisture-sensing closed-loop system for a single dryer, or automating an entire plant, technology is available to take the guesswork and worry out of resin drying. Using a modular approach allows processors to start simple and build more capabilities over time.

Read MoreFive Ways to Increase Productivity for Injection Molders

Faster setups, automation tools and proper training and support can go a long way.

Read MoreReal-Time Production Monitoring as Automation

As an injection molder, Windmill Plastics sought an economical production monitoring system that could help it keep tabs on its shop floor. It’s now selling the “very focused” digital supervisor it created, automating many formerly manual tasks.

Read MoreProcessing Megatrends Drive New Product Developments at NPE2024

It’s all about sustainability and the circular economy, and it will be on display in Orlando across all the major processes. But there will be plenty to see in automation, AI and machine learning as well.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More