When It Comes to Maintenance Trust Your Nose (and Ears and Eyes)

An ever-growing number of sensors on injection molding machines provide real-time transparency into a press’s inner workings, but the low-tech sensors humans come with are still vital to keeping a plant running.

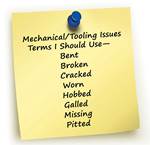

In the same way a pilot inspects an aircraft prior to a flight, John Wiley believes machine operators would benefit from a walk around at the start of their shift. Business development manager at Engel, Wiley has worked on the care and maintenance of production equipment at both the processor and OEM level for the past 34 years. He shared his three-plus decades of experience in a webinar on machine maintenance.

During that habitual walk around, Wiley says machine operators should use their eyes, ears and nose to sniff out, sound out, and spot out issues while they’re still small. “Our sense of smell can identify a lot,” Wiley said. Do you smell plastic burning? There could be a nozzle leak. Is there a burning rubber smell? Likely to be an electrical issue. Can you smell hydraulic oil? Hydraulic fluid is leaking from somewhere.

Listening to a machine can reveal a lot too, and you should trust your ears if something sounds off. The squeal of a bearing, whine of a hydraulic pump, chatter of hydraulic valve, slamming of the mold, bouncing of an ejector plate—all tell a story about your machine’s current—and likely deteriorating—health.

Wiley also stressed trusting your eyes. Many machines have collection areas for spills, if these are filling with oil—or if the operator is adding oil to the press before every shift—you should find and tag the leak to get it addressed sooner than later.

“If I’m putting oil in every day, I’ve got a leak; if the machine is overheating, the heat exchanger plugged,” Wiley said. “Walk around inspections can catch these issues when they’re small.”

Wiley encouraged attendees to be vigilant, with most of these investigations involving a “a clear site inspection with both feet on the ground.” If there is standing oil, the operator or maintenance worker should secure the machine and investigate further. “It’s far better to stop it, fix it, put it back in maintenance than it is to ignore,” Wiley said. “It’s so important that you do it in its infancy.”

Related Content

-

Medical Tubing: Use Simulation to Troubleshoot, Optimize Processing & Dies

Extrusion simulations can be useful in anticipating issues and running “what-if” scenarios to size extruders and design dies for extrusion projects. It should be used at early stages of any project to avoid trial and error and remaking tooling.

-

Use These 7 Parameters to Unravel the Melt Temperature Mystery

Despite its integral role in a stable process and consistent parts, true melt temperature in injection molding can be an enigma. Learning more about these seven parameters may help you solve the puzzle.

-

Injection Molding: Focus on these Seven Areas to Set a Preventive Maintenance Schedule

Performing fundamental maintenance inspections frequently assures press longevity and process stability. Here’s a checklist to help you stay on top of seven key systems.