Overfeeding Can Cause Surges, Too

Surging can be caused by feed restrictions, as covered in another column, and also by over-feeding or under-melting, discussed here.

In the last issue I wrote about surging that results from feed restrictions. But surging can also be caused by over-feeding or under-melting. That is, the feed rate can exceed the melting capacity of the screw, creating plugging in the melting section.

This can be depicted with the conventional melting pattern for a single-flighted screw, as shown in the illustration to the right. The melt film forms on the barrel, initially by friction and conducted heat, afterward by shearing of the solid bed in contact with the barrel. As the polymer melts at the barrel wall, it is scraped off by the advancing flight and a melt pool is formed on the pushing side of the flight. This mechanism continues until the end of the melting section.

The melting rate is controlled by the shear stress in the film near the barrel wall, the barrel temperature, the thermal and viscous properties of the polymer, and the screw design. Once the limits of these factors are exceeded, the channel will become completely filled with solids. The melt pool is forced downstream due to the increasing pressure resulting from the channel plugging with the higher viscosity solids. This is manifested as a surge at the discharge.

In mild cases, the increased pressure results in increased melting rate and an unplugging of the channel, with a reformation of a new melting pattern. In most cases, however, the melting pattern is destroyed at that point, with the remaining solid bed being broken up and forced downstream. Once the melting pattern is broken up, the remaining unmelt is difficult to melt and results in poor melt quality.

Either way, the plugging immediately begins to reform, setting up another surge. The pattern in a barrier screw is much less distinct due to the mechanical separation of the solid and melt by the barrier flight.

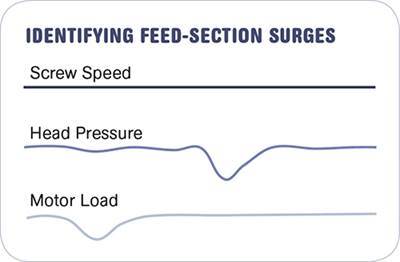

This type of surging is characterized by a sudden increase in output and an almost simultaneous increase in motor load. The frequency is very fast, with sharp spikes in both the discharge pressure and motor load. It is different from the feed-limiting surge in those two characteristics. (The latter manifests itself as a sudden decrease in output and lasts from a few seconds to several minutes.) Spikes from a melting-limited surge can be somewhat rhythmic but generally have no specific pattern or time cycle.

As noted in last month’s column, if you have a melt pump, it may require a multi-channel data logger to plot screw speed, head pressure, and motor load to see the pattern.

Alternatively, you can get this data using manual control of the pump speed, or by allowing the extruder to drive the melt pump by turning the pump motor off and allowing the extruder to continue. Otherwise, the drop in suction pressure behind the melt pump will cause the screw speed to change, resulting in a motorload change masking the surging behavior. Surging is easily recognized with a melt pump, as you can see and hear the screw speed changing continuously, but you can’t tell what is causing it without some analysis.

There are just a few ways to minimize or eliminate this type of surge. You can try to add more barrel heat to assist melting, or reduce the screw speed to lower the melting requirement. Or you can get a new screw with more melting capacity or less feed capacity. The key is to first analyze the surge before determining possible corrective actions.

Related Content

Improve The Cooling Performance Of Your Molds

Need to figure out your mold-cooling energy requirements for the various polymers you run? What about sizing cooling circuits so they provide adequate cooling capacity? Learn the tricks of the trade here.

Read MoreThe Importance of Melt & Mold Temperature

Molders should realize how significantly process conditions can influence the final properties of the part.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MoreHow to Get Rid of Bubbles in Injection Molding

First find out if they are the result of trapped gas or a vacuum void. Then follow these steps to get rid of them.

Read MoreRead Next

Solving Feed-Related Surging

Understanding the causes of surging can help troubleshoot and correct it.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read More

.jpg;width=70;height=70;mode=crop)