Gravimetric Color Dosing for Injection Molders

There are various methods to accomplish color dosing. Some models employ rotating discs with holes or slots to capture pellets and drop them into a mix. They provide good accuracy but can be problematic if the size or shape of the colorant changes. Most color feeders rely on screws of various diameters and a variable speed motor to adjust the rate of colorant dispensed so those are the type we will discuss here.

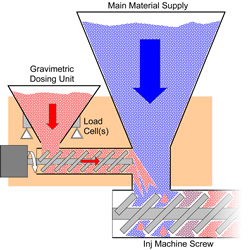

The purchase price of gravimetric dosing equipment varies considerably so be sure to compare features and pricing. One version of gravimetric feeder is about the same price of volumetric feeders and offers all the full-featured value of more expensive gravimetric models. Gravimetric dosing equipment enables injection molders and extrusion processors to reduce color and additive consumption, increase control over product quality, and document color usage for each production run. They can be mounted directly to the throat of most molding machines or extruders.

Load cells accurately monitor the loss-in-weight of colorant in the hopper.

- Easy-to-use controller allows use in extrusion and injection molding operations.

- All dispensing parameters are easily entered.

- Automatic adjustments are made when a minor accumulated error is detected.

- Low initial cost + high accuracy = fast payback

The loss-in-weight operation adds a new dimension of accuracy. Gravimetric systems generate a wealth of data on color consumption, adjust color metering far more accurately to account for process variations and to compensate for vibrations on fast-cycling molding presses. Volumetric feeders do not monitor the weight of colorant as it is fed to the processing machine and thus generate no data about how much of the material is actually consumed from moment to moment.