Fakuma: Wittmann Battenfeld to Launch Machine Line at Friedrichshafen Fair

In addition to introducing its new SmartPlus line of servo-hydraulic injection molding machines, Wittmann Battenfeld will feature multiple machines at its booth and stream video of other cells from its labs.

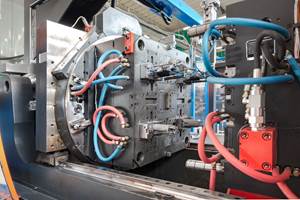

Wittmann Battenfeld is introducing the new SmartPlus line of servo-hydraulic injection molding machines at Fakuma 2021 (Oct. 12-16; Friedrichshafen, Germany) at booth 1204 in hall B1. Among the notable advances on the SmartPlus is the new B8X control system, which includes some components designed in house and offers higher frequency, shorter response times that reportedly result in more repeatable processes. The new SmartPlus also utilizes the KERS energy recovery technology originally developed for the EcoPower, further boosting its efficiency. Currently being field tested at select customers, the SmartPlus will be available commercially starting in the fourth quarter with clamping forces from 60 to 180 tons.

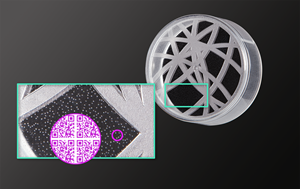

The SmartPlus servo-hydraulic injection molding machine will be available commercially starting in the fourth quarter with clamping forces from 60 to 180 tons.

At the show, Wittmann will be running a SmartPlus 180/750 equipped with the HiQ Flow application software and the new CMS-Light condition-monitoring system, which tracks wear and metrics on a range of service-relevant machine parameters. The machine will receive material from a Gravimax G14 gravimetric blender and parts will be handled by a Primus 26T robot at the heart of an Easy Cell designed and manufactured by Wittmann Battenfeld Deutschland in Nuremberg. The Easy Cell is a mobile automation cell mounted on casters, which offers a complete range of CE-compliant safety features but doesn’t require a safety gate, which dramatically reduces its footprint.

The SmartPlus 180/750 will be molding a hub-cap for lawn mowers from a mix of virgin and regrind PP, using a mold supplied by German firm Uralan. The HiQ Flow software will be used to ensure good parts are molded, compensating for the viscosity fluctuations of the mixed material stream.

Wittmann 4.0, LSR Multimaterial Molding and More

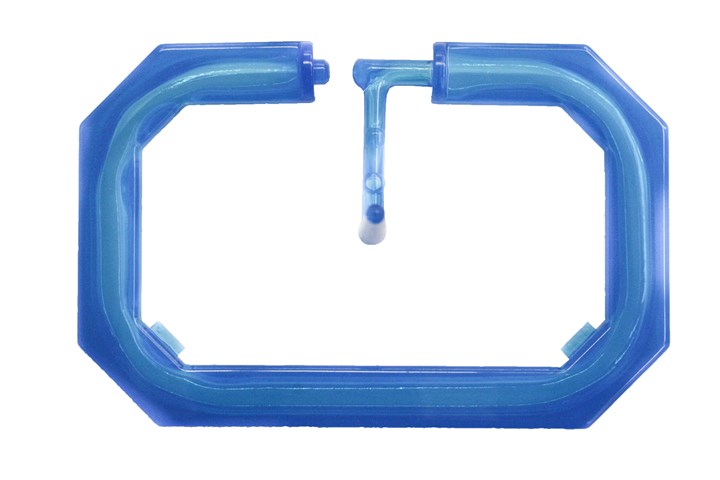

Additional machine displays will include an example of digitization supporting production of a medical application running on a all-electric EcoPower 55 injection molding machine. The EcoPower’s UNILOG B8 control system will utilize the Wittmann 4.0 platform to control and monitor a Wittmann W918 robot, an ATON plus H30 segmented wheel dryer, three TEMPRO plus D series temperature controllers and the TEMI+ MES system from the press’s control screen. Using a Wittmann 4.0 router, the system ensures that the connected auxiliaries are sufficient for the product to be molded and whether additional equipment is needed. The electronic mold data sheet will also be used by the UNILOG B8 control. The cell will mold a medical hose clamp from an 8-cavity tool supplied by WILAmed. The EcoPower is equipped with HiQ Flow to compensate for viscosity fluctuations, HiQ Melt for material quality monitoring and HiQ Metering for active closing of the check valve. Here too, an Easy Cell automation unit from Wittmann Battenfeld Germany is applied.

This medical tool clamp will be molded from an 8-cavity WILAmed tool on an EcoPower machine at Fakuma.

In another machine display a multicomponent MicroPower will mold a support ring from PC with a silicone membrane. The cleanroom-ready two-component MicroPower 15/10H/10H CombiMould has two horizontally configured injection units and a completely encapsulated rotary disc for spinning the mold to receive different materials. All heating, temperature sensors, water tempering, core-pull pneumatics and sensors, as well as the blow-off valve, are mounted on the rotary disc. The multi-component MicroPower applies a two-step screw-and-plunger with a shot volume of 4 cm³. Nexus supplied the mold and the LSR dosing unit, which features a new Servomix dosing system utilizing an OPC-UA interface.

All machines in the Wittmann booth will be equipped with IMAGOxt software. A module within the MES TEMI+ platform, IMAGOxt visualizes and monitors the machine’s energy consumption. This can include the creation of user-defined KPIs and personalized alarm signals. The latest AIRMOULD internal gas-pressure technology developments will be presented in a separate AIRMOULD center at the booth.

Streaming More Cells Live

Beyond Friedrichshafen, Wittmann Interactive will stream additional production cells to the fair from technical labs in Kottingbrunn, Austria; and Meinerzhagen and Nuremberg in Germany. These displays include CellMould light-weight technology running on a MacroPower 1100/12800 that will mold a seat carrier from PP for a German sports car model using a single-cavity mold supplied by Frimo.

Inline recycling with a SmartPower 60 Ingrinder will be demonstrated from Meinerzhagen. The SmartPower will mold a can with a lid made of PS using a double 2-cavity mold. Other displays include injection compression molding (ICM) of a thin-walled cup from Kottingbrunn using a high-speed EcoPower Xpress 160/1100+ with a Wittmann robot for part removal. The cups will be molded from a 4-cavity mold supplied by Swiss firm Glaroform. In ICM, melt is injected into a partially open mold. The actual forming process involves pressing the melt into the cavity after the mold has been closed. This allows the cavity to be filled under lower pressure, which reduces warpage.

Injection compression molding (ICM) of a thin-walled cup will be streamed to Friedrichshafen from Wittmann’s lab in Kottingbrunn.

In Meinerzhagen, the new Airmould internal gas-pressure technology will be demonstrated on a SmartPower 120/525, molding a towel holder from polystyrene. With Airmould, nitrogen is injected into a partially or completely filled mold cavity, creating a hollow structure within the part, reducing cycle times and improvising exterior surface finish.

Airmould internal gas-pressure technology will be used to create this hollowed-out towel holder from PS.

From Nuremberg, the company will use Wittmann Interactive to showcase a joint inmold decoration project involving functional foil and foil feeder supplier Leonhard Kurz and Syntech Plastics to create an interior covering for the automotive industry with a functional surface. A SmartPower 300 production cell with automation and Wittmann 4.0 integration will create the parts, which will also be on hand at Wittmann’s and Leonhard Kurz’s Fakuma booths. The SmartPower is equipped with foil feeding and foil pre-heating units, including IMD Vario with pre-heating and thermoforming insert molding. The Expert-Coining package permits parallel mold movements during injection.

Related Content

Fakuma 2023: Wittmann Battenfeld Expands All-Electric Line, Direct-Current Capabilities

Wittmann Battenfeld will introduce the new EcoPower B8X injection molding machine line and show direct current as an energy source for a concept machine that will power its own robot.

Read MoreZAG Equipment Sales Partners with Portugal’s Plasdan of Portugal

Under the agreement, ZAG will sell and service Plasdan’s add-on injection units and fully electric rotary tables for multicomponent injection molding.

Read MoreMold, Hot Runner, Digitization and Process Monitoring at K 2022

The Barnes Group’s Molding Solutions division companies will highlight new mold and hot runner technologies at its own booth and at several machinery partners during K 2022.

Read MoreMolder Opts for Machine Flexibility for Complex Jobs

AE Plast opted for tiebarless multimaterial Engel victory machines as it took on complex parts for the appliance and power tool market, including a 3K housing for Dremel’s rotary tool.

Read MoreRead Next

Lightweight Composites & Superfast Container Molding at Fakuma Show

Overmolded UD tapes replace organosheet with major weight savings. And 4 PP cups molded in 1.55 sec.

Read MoreFakuma Show Goes On (Digitally) for Wittmann Battenfeld

Self-contained inline scrap integration; medical, LSR, and packaging Cells; an MES Upgrade and more to be introduced virtually.

Read More