Biobased, High-Performance Aliphatic Nylon 46

DSM’s Stanyl B-MB 100% biobased version of the company’s flagship Stanyl 46 and said to be an ‘industry-first launch’ of a biobased high-temperature nylon.

A new 100% biobased content high-performance aliphatic nylon 46 has been added to the Stanyl nylon 46 portfolio of DSM Engineering Materials. Designated Stanyl B-MB (Biobased Mass Balanced), this more sustainable version of the company’s flagship material, reportedly offers the same high performance offered by its virgin counterpart. Its excellent high-temperature mechanics (melting temperature of 554 F/290 C), superior flow and processing, and distinguished wear and friction resistance make it ideal for high-temperature applications in automotive, electronics, electrical, and consumer goods industries, such as USB connectors, automotive and industrial actuator gears, powertrain timing chains, bearing cages, and food contact conveyors.

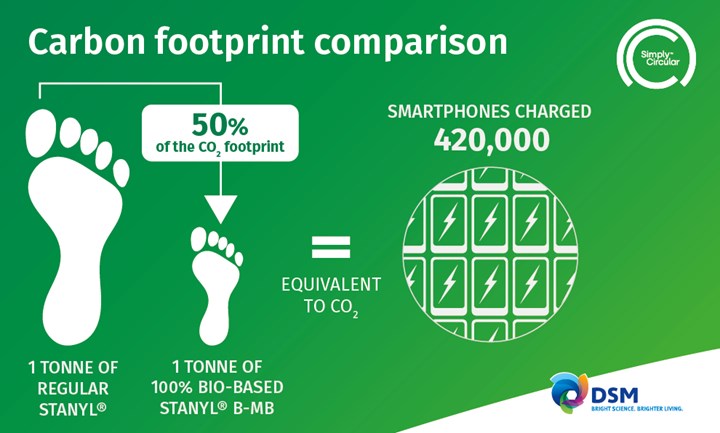

Using the maximum possible levels of biomass-waste feedstock, it enables DSM to halve the carbon footprint of this product line and, in turn, of the Stanyl B-MB-based products of its customers. This ‘industry-first launch’ of a 100% biobased high-temperature nylon underlines the company’s ongoing commitment to helping customers fulfil their sustainability ambitions by making planet-positive choices and supporting the transition to a circular and biobased economy.

Global production of biobased products roughly doubled between 2015 and 2020, but the materials industry urgently needs to accelerate the shift to sustainable feedstocks, according to DSM, which has committed to providing bio- and/or recycled-based alternatives for its entire portfolio by 2030. Stanyl B-MB is a fully ISCC+-certified massbalancing solution, and has been shown to deliver exactly the same characteristics, performance, and quality as conventional Stanyl, yet its production now generates a carbon footprint up to 50% lower than the fossil-based original. In practice, this means a 3.3-ton CO2 reduction per ton produced – equivalent to charging 420,000 smartphones, according to DSM.

Related Content

-

Volume Resin Prices Move in Different Directions

PE, PP, PVC, and ABS prices slump, while PS, PET, PC, and nylons 6 and 66 prices rise.

-

Prices of Volume Resins Drop

Price relief is expected to continue through the fourth quarter for nine major commodity and engineering resins, driven by widespread supply/demand imbalances.

-

Tracing the History of Polymeric Materials: Acetal

The road from discovery in the lab to commercial viability can be long, and this was certainly the case for acetal polymers.

.png;maxWidth=970;quality=90)