Fine Silica Fillers Improve Cost/Performance of 3D Printing Resins

AGC Chemicals says resins infused with new Solesphere fine silica gels improve product quality, performance and processing efficiencies for all three major 3D printing processes.

A family of fine silica gels has been developed by AGC Chemicals Americas, Exton, Penn., that are said to enhance the properties and performance of 3D printing resins. When incorporated into such resins, the new Solesphere family of fillers has been shown to have improved processing efficiencies for all three major 3D printing processes – photopolymerization, material extrusion (FDM) and powder bed fusion (SLS) and to result in products with improved quality and performance. Moreover, their use can reduce the cost of 3D printing build resins, and can also add desirable performance characteristics like dimensional stability, temperature properties and tensile strength.

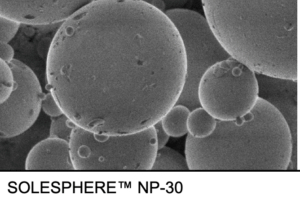

Spherical Solesphere silica gels have a smooth surface, large particle size and low surface area, all of which help to lower the viscosity in the final resin formulations. With purity over 99%, these fine silica gels do not alter the physical properties or chemical interactions in the polymer matrix of the resin. Their low particle size distribution provides consistent results for each batch of material, and their active chemical surface enables good chemical bonding and interactions with resins and other fillers.

Solesphere gels have been shown to impart high tensile strength, increased stiffness/flexural strength, improved dimensional stability, easy dispersion in a polymer matrix, thermal resistance and improved heat deflection temperature. They also help to mitigate phase separation and delay the settling process during storage. They can be used with ABS, PC, nylons and other crystaline polymers where high strength, temperature resistance and dimensional stability are critical.

Solespher silica gels have particle sizes from 3 to 20 μm, pore diameters up to 120 Å and surface areas from 40 to 800 m2/g.

AGC offers four lines of Solesphere silica gels:

▪ Multi-porous H-Series: High Specific Surface Area

▪ Multi-porous H-Series: High Oil Absorption Capacity

▪ Multi-porous L-Series: Low Specific Surface Area

▪ Nonporous NP-Series

Related Content

-

Daimler, OMIC Evaluate Wire-Fed DED for Moldmaking

3D printing a core and cavity on machine from Gefertec, followed by machining, allowed for a complete mold tool to be produced in three days.

-

New Tool Steel Qualified for Additive Manufactured Molds and Dies

Next Chapter Manufacturing says HTC-45 — an optimized H-13 — will offer superior thermal transfer and longer tool life.

-

3D Printing of Injection Molds Flows in a New Direction

Hybrids of additive manufacturing and CNC machining can shorten tooling turnaround times.