Injection Molding: Artificial Intelligence Predicts Part Quality

AI software “learns” via DOE the influence of process variables on part quality and applies that “learning” to make good/bad part determination in production.

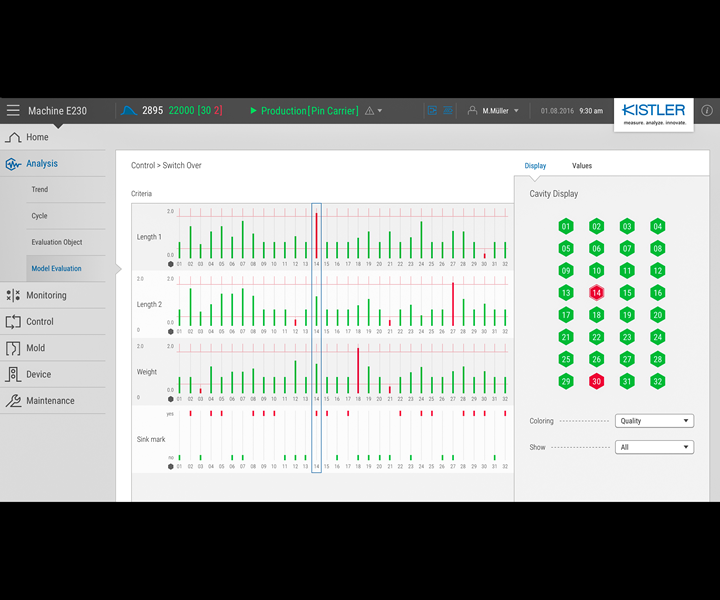

The K 2019 show made clear that artificial intelligence (AI) is the leading edge of innovations to create smarter machines and production systems (see show report in January issue). Kistler Instrument revealed it is using AI to predict part quality based on process data. Kistler’s newly commercial ComoNeo Predict software (pictured) is powered by STASA QC, developed by Steinbeis Angewandte Systemanalyse GmbH (Steinbeis Applied System Analysis) in Germany. STASA QC uses machine learning to predict quality data such as part dimensions (or strength) based on the cavity-pressure curve derived from in-mold sensors. The result is automated QC without time-consuming metrology tests.

Kistler’s ComoNeo Predict incorporates STASA QC software that uses artificial intelligence to predict part quality from cavity-pressure data.

The STASA QC software is “trained” by means of DOE configured by the software and executed automatically on an injection machine. The DOE involves five to seven repetitions of variations of three parameters—hold pressure, hold time, and temperature—in three steps each. The trial parts are measured and the data entered into STASA QC. The software then determines the influence of each parameter of part quality. (Cycle time can also be included in the optimization.) The result is a “systematic process setup” in which the user enters the upper and lower quality limits for the part, and the software determines how to optimize settings to achieve the desired quality. In production, ComoNeo Predict can be used to make accept/reject quality decisions on each cycle based on the cavity-pressure data.

At the K show, Sumitomo (SHI) Demag said it is experimenting with STASA QC, which it interfaced with its NC5 machine controls.

Related Content

-

KraussMaffei Launches Two Additive Manufacturing Lines at K 2022

Long established in injection molding, extrusion and polyurethane reaction process machinery, 184-yr-old KraussMaffei prepares to enter the industrial additive manufacturing market.

-

Mold Opaque White PET Bottles – Without Pigment

Trexel and Husky are cooperating on molding recyclable opaque white preforms for PET bottles, which provide a light barrier using foam instead of pigment.

-

How Was K 2022 for Blow Molding?

Over a dozen companies emphasized sustainability with use of foam and recycle, lightweighting and energy savings, along with new capabilities in controls, automation and quick changeovers.

.png;maxWidth=300;quality=90)