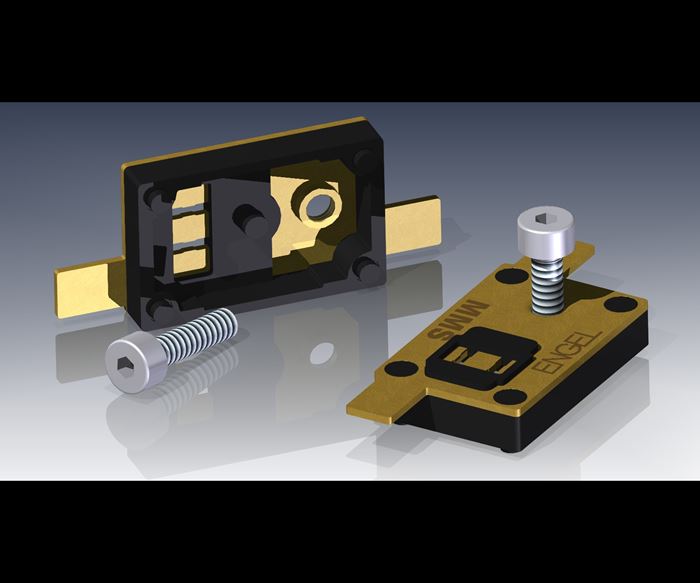

Integrated Metal/Plastic Processing for Teletronics

Engel combines metal punching and tapping with injection overmolding in one integrated process.

Thermal switch housings, used to monitor electric motors in cars or home appliances, are usually produced in a complex, multi-stage process. As a rule, the metal components are punched and overmolded at entirely different locations. This requires considerable logistics overhead and ties up a lot of material and work in process, since two independent processes must be started up.

Engel is combining these operations in a single integrated production flow. Engel developed the system together with MMS Modular Molding Systems of Austria, a specialist in turnkey production lines for metal/plastic hybrids. The process starts with feeding thin brass sheet from a coil through a punch press, where the brass also has a thread servo-electrically tapped. The brass carrier plates, still on a continuous reel, are fed into a vertical, 38.5-ton Engel insert 60V/35 press for overmolding with glass-filled nylon. Camera inspection and high-voltage testing integrated into the tool ensure 100% quality control. Eight finished parts leave the cell every 20 sec.

Related Content

-

SABIC Composite Hybrid Battery Cover Enhances EV Safety, Efficiency

SABIC collaborated with Engel, Siebenwurst, Forward Engineering, Ensinger and Envalior to develop a thermoplastic composite EV battery cover, combining strong structural performance, flame retardancy and design efficiency.

-

Benchtop LSR Injection Molding Machine Launches

APSX LLC, which previously marketed the APSX‑PIM desktop thermoplastic injection molding machine, has debuted the APSX‑LSR — a benchtop liquid silicone rubber (LSR) injection system.

-

Injection Molded Enclosures Plug into Potential Electric Vehicle Battery Applications

In partnership with material suppliers, Engel is proving out injection molded thermoplastic-based concepts for electric vehicle battery housings, utilizing production tools and dedicated machines at its large press factory in St. Valentin, Austria.