LSR Machine and Injection Unit Designed for Low-Shot Volumes

BOY will present its XS machine running an LSR application created in collaboration with the University of Kassel at DKT 2022 (June 27-30; Nuremberg, Germany).

Dr. Boy GmbH & Co. KG will showcase a liquid silicone application running on a BOY XS injection molding machine at the Deutsche Kautschuk Tagung (DKT; June 27-30; Nuremberg). Boy notes that the application—LSR syringe stoppers—and the machines injection unit was created in close cooperation with the Application-Centre for Plastics Processing UNIpace, which is part of the Institute for Materials Technology at the University of Kassel.

The parts are molded from a Wacker two-component liquid silicone Silpuran 600/50, with the project reflecting UNIpace’s goal to more closely combine scientific research in the field of plastics processing with the practical production of injection molded parts for the medical sector.

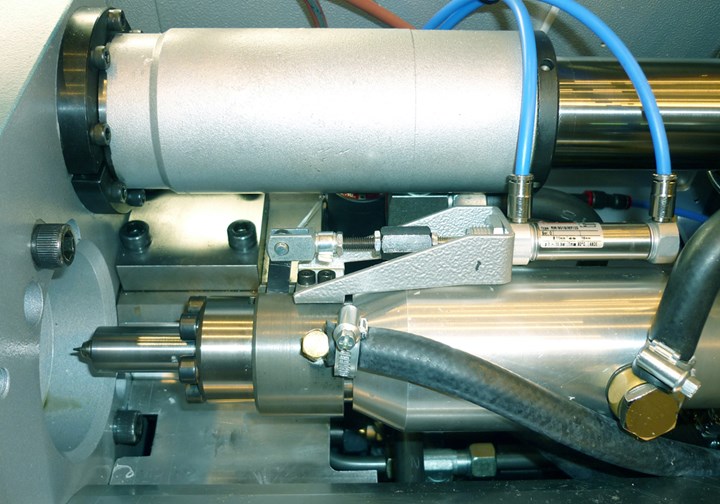

The BOY XS injection molding machine features 100 kN (10 tons) clamping force, and what Boy describes as a special silicone unit. This unit has a 14-mm screw diameter and a more precise, spring-loaded ball non-return valve. The Procan ALPHA machine control system manages the valve-gate nozzle, cold runner and silicone pump. EMT Dosiertechnik will supply the LSR-pump, with 20-liter capacity. The pump will meter silicone components into the four-cavity mold via a mini cold-runner-system supplied by Günther Heisskanaltechnik GmbH.

The finished parts, weighing 0.5g each and still 180 C, are removed from the mold via a stripper plate.

A Boy spokesperson told Plastics Technology that its collaboration with UNIpace included work the Günther micro cold runner system. That unit’s

Boy will showcase an LSR-equipped injection molding machine featurin a 14-mm screw and a more precise, spring-loaded ball non-return valve.

Photo Credit: Boy Machines

four nozzles are pneumatically driven shut-off nozzles, which are designed for lowest shot volumes and to be used in small machines with limited mold space.

Regarding the injection unit, the spokesperson said the whole machine and especially the injection unit are designed for low shot-volumes. There are two LSR-injection units available with screw diameters of 8 or 14 mm and theoretical maximum shot volumes of 1000 or 6100 mm³. “Depending on these low screw diameters, we had to design extremely fast acting non-return-valves,” the Boy representative said, “since there are no spring-loaded valves available for these low-screw diameters.”

Related Content

-

Silicone Elastomer Course Returns

After completely filling the classroom last year, the Silicone Elastomers Technology and Fabrication course returns to Pomona, Calif. Jan. 31-Feb. 3.

-

Minnesota Rubber and Plastics Opens Innovation Center

The plastics and rubber compounder and molder has opened the 9000-ft2 center that’s intended to help speed product development with design, prototyping, testing and production capabilities.

-

Fakuma 2023: Wittmann Battenfeld Expands All-Electric Line, Direct-Current Capabilities

Wittmann Battenfeld will introduce the new EcoPower B8X injection molding machine line and show direct current as an energy source for a concept machine that will power its own robot.