More Power for Dryer Controller

Allows users complete pump and receiver control in a cell, in a user-friendly and straightforward control system.

Maguire has made its Ultra dryer touchscreen controller even more powerful and feature rich by integrating its FlexBus Lite software into the platform’s powerful Arm Cortex microprocessor. FlexBus Lite, a standard feature on all touchscreen blender controls, is now integrated into the Ultra dryer touchscreen controls, allowing users complete pump and receiver control in a cell, in what’s described as a user-friendly and straightforward control system.

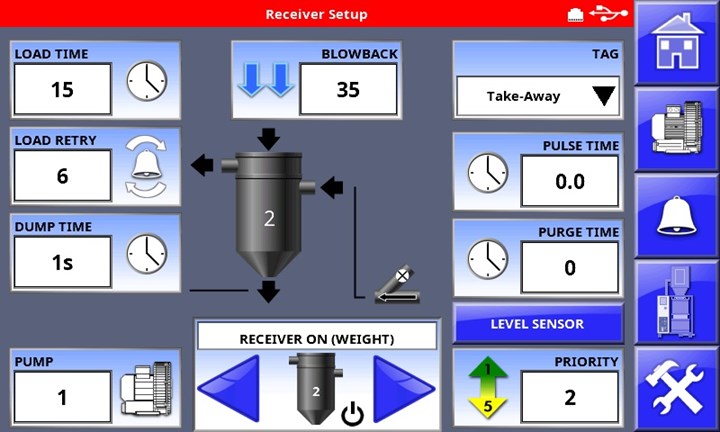

FlexBus Lite comes with an intuitive receiver and pump control with features typically only found on larger central system controls. It allows control of 1 vacuum pump and full system functionality control of up to 10 materials receivers. The Icon based touchscreen shows each of the receiver’s activity in real time whether it is calling for material, receiving material into it, or showing material discharging. The pump and receiver settings can be easily adjusted in real time by the operator.

“With the dryer, vacuum chamber and material retention hopper on load cells you are able to completely regulate the drying rate to the process rate. This allows the operator to program a shutdown to any specific day and time,” said Frank Kavanagh, v.p. sales and marketing. “The control system then monitors the rate so that the loader will stop calling for material and the dryer will be empty. With the control system monitoring the rate, this makes material changes even easier.”

FlexBus Lite on the ULTRA dryer offers full feature conveying control and is designed to handle single or multiple dryers (up to 10 receivers) with ground level receiver and pump control. With one operator friendly touchscreen you can control the dryer’s onloading and offloading.

The fact that it can control of up to 10 receivers means that one Ultra dryer can manage the conveying of an entire cell. Remote control capability makes mezzanine and elevated installations easier than ever for the operators.

There are no additional controls necessary with FlexBus Lite; the control system can reportedly work with any Maguire product and also any third-party system.

Related Content

-

PiovanGroup Rebrands, with Mostly Minor Name Changes

For the most part, subsidiary company names will remain, with slight modifications meant to enhance the Group’s identity.

-

Why (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

-

Compact, Mobile Dryer Has Unique Conveying Capabilities

Mobile dryer includes closed-loop conveying to minimize the use of ambient air for resin movement.