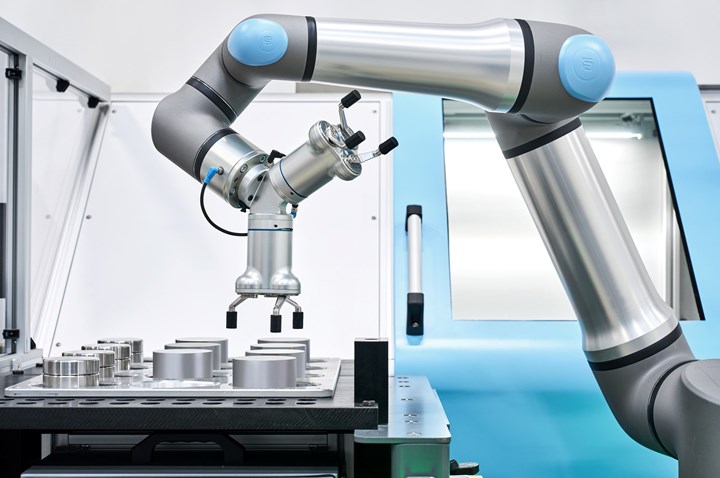

New Cobot Has More Reach, Greater Payload, Same Footprint

Universal Robots says the UR30 cobot has a 30-kg payload and 1,300-mm reach with a 245-mm-diameter footprint.

At the iREX international robotics trade fair in Tokyo, Universal Robots (UR) launched a new collaborative robot (cobot) with a 30-kg payload. The new UR30 is the next-generation cobot for the company, expanding on the capabilities of its predecessor, the UR20.

Seeking a faster, smaller and stronger cobot, UR said the UR30 is well suited for lifting heavier items or working in areas where space is more constrained, and flexibility is needed from a compact unit. The robot weighs 63.5 kg and offers 1,300 mm of reach, with UR noting that the 245-mm footprint means it doesn’t take up more space than the average human would.

The UR30 features a new tool flange featuring six bolts and a larger diameter in a size that is still ISO standard. This new design will be standard for high-payload applications going forward, according to UR. UR says in machine-tending applications, the added payload and reach position the UR30 to take on jobs where the cobot arm holds inserts entering a machine, as well as finished parts exiting it.

A steady mode enables it to remain still during high-torque applications, and the UR30 has 17 configurable safety features that enable it to continue to work in close quarters with people. UR says it is already taking orders for the new cobots, with deliveries to begin in the first quarter of 2024.

In a press conference launching the cobot, Kim Povlsen, UR president, said the global market for cobots has crossed the $1 billion threshold, with the figure forecast to at least double by 2027. The company forecasts that over the next five years, 25% of all capital expenditures in manufacturing will be directed toward automation, with 20 million jobs out there that could currently be automated today and in coming years.

UR notes that it created its first commercially viable cobot — the UR5 — in 2008, based on new joint design and informed by the company’s first 18 years of product development. The UR20, with a 20-kg payload, was the first robot of its generation but was actually 6th generation within UR. Going forward, UR expects numerous jobs and functions will remain applicable to the UR20.

The higher 30-kg payload on Universal Robots UR30 cobot enables it to handle finished parts and inserts in the same process movements. Photo Credit: Universal Robots

Related Content

-

Drones and Injection Molding Ready for Takeoff

Drones and unmanned aerial vehicles (UAV) are approaching an inflection point where their production volumes — and functionality — will increasingly point to injection molding.

-

Ensuring Repeatability: The Key to Effective Injection Molding Automation

One of automation’s key promises is repeatability: the same movement to the same location, time and time again. But to achieve that, all elements involved — robot, machine, EOAT, mold — must be in and stay in alignment.

-

Cobot Creates 'Cell Manufacturing Dream' for Thermoformer

Kal Plastics deploys Universal Robot trimming cobot for a fraction of the cost and lead time of a CNC machine, cuts trimming time nearly in half and reduces late shipments to under 1% — all while improving employee safety and growth opportunities.

.png;maxWidth=300;quality=90)