NPE2018 Auxiliaries: A Path to Industry 4.0 Emerges

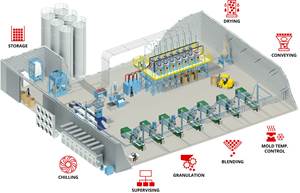

Industry 4.0 dominated the news in auxiliary equipment at the show, but many questions remain for both suppliers and processors.

As promised prior to the show, Industry 4.0 featured prominently in the booths of auxiliary equipment suppliers at NPE2018. But just as processors are trying to figure out how it will impact their businesses, machinery suppliers are likewise puzzling out how they will bring the technology to market.

Conversations with those suppliers in Orlando revealed some key questions that remain to be answered, and the responses ultimately will affect the products that processors will be able to buy. Top issues to resolve: Will equipment suppliers build their own 4.0 platform or partner with firms that have already created programs, albeit often for industries outside plastics processing?

And if these equipment OEMs want their machines to “talk” to other pieces of machinery in a customer’s plant, what language should they teach them to ensure a fully conversant cell?

The outlines of answers came more into focus in Orlando, as some suppliers announced new or augmented 4.0 capabilities that they’ve developed independently or in partnerships; and movement towards that common language, OPC-UA, also advanced.

Development of machine-to-machine communications standards is being spearheaded by the European (EUROMAP) and German (VDMA) associations for plastics and rubber machinery makers in collaboration with other associations, including NPE organizer the Plastics Industry Association (PLASTICS).

At the NPE2018 press breakfast immediately prior to the show’s opening on May 7, Glenn Anderson, show chairman and senior v.p. of sales, marketing and product management at Milacron, noted that suppliers on both sides of the Atlantic continue to collaborate on OPC-UA. “Industry 4.0 is here to stay,” Anderson said, “and we’re going to have to come up with standards. A very, very important aspect of our business is that we’re going to have to have policies.”

“The machine is getting smarter than man. It approaches AI.”

Progress on the injection molding front was announced at the show during a EUROMAP press tour where several suppliers discussed the newly created EUROMAP 77 standard for data exchange between a press and an MES (manufacturing execution system) central computer. EUROMAP acknowledged in a press release the need to address communications for auxiliary equipment within a cell, citing two standards in development—EUROMAP 82, data exchange between injection molding machines and temperature-control devices; and EUROMAP 79, data exchange between presses and robots.

At the show, Siemens announced that it was adding MachineSense LLC’s suite of vertically integrated Industrial Internet of Things (IIoT) programs to its MindSphere platform. As a Siemens Silver partner, MachineSense will gain access to educational materials and, perhaps more importantly, fellow members, to further promote its IIoT to industry. MachineSense provides power-quality monitoring, energy management, and predictive and preventive maintenance.

Conair, meanwhile, launched its Uptime Guaranteed initiative at NPE2018, which is powered in part by its new Smart Services offering, a Cloud-based database where equipment and process data are transmitted to the Cloud for analysis by proprietary algorithms. Conair developed those algorithms, while it partnered with Maven Machines to create the platform. That firm, based in Pittsburgh, was founded on a mobile Cloud-based technology to provide fleet management for the transportation industry, including trucking and rail. “The intention is to pull data from our huge installed base of equipment,” explains Sam Rajkovich, Conair’s v.p. of sales and marketing. “Our eventual goal is AI (artificial intelligence); getting the machine to understand what is going on and fix itself.”

MACHINE LEARNING, MACHINE INTELLIGENCE

The concept of AI or machine intelligence came up more than once at NPE. Machine intelligence can only be achieved if machines can “learn” on their own, and many suppliers see that as the future of machinery in plastics and beyond.

David Preusse, president of Wittmann Battenfeld, discussed the burgeoning intelligence of its equipment at the show, specifically citing the company’s Smart Removal program for robots, which can teach themselves the fastest path and velocity into the cavity to pull parts. “The machine is getting smarter than man,” Preusse states. “It approaches AI.”

On the Industry 4.0 front, Preusse noted that Wittmann Battenfeld engineers sit on the committee that’s developing standards, and his company was displaying the newest standard—EUROMAP 77—during NPE2018, via a collaboration with ERP and MES software provider IQMS, whose software was fully integrated into a Wittmann Battenfeld molding cell, collecting and analyzing production data in real time.

If machines can talk to other machines, there is, of course, the possibility that unwanted devices could surreptitiously join the conversation, breaching a network. Wittmann Battenfeld stressed IT security for its connected offerings of auxiliaries, specifically touting its Wittmann 4.0 router, housed within the molding machine, which automatically assigns IP addresses and security certificates to any equipment added to a cell.

In addition to recognizing what equipment is in the cell and assigning the proper “recipe” to a temperature-control unit, for instance, given the installed tool; or having a robot automatically “home” itself, Preusse said this connectivity alleviates control screen fatigue. “Today within a cell there are too many displays,” he said. “You walk up to cell and see 10 different controllers. With Industry 4.0 you can get all that on a single control.”

Preusse acknowledges that Wittmann Battenfeld is in a unique position when it comes to such comprehensive connectivity, as it makes molding machines, auxiliary equipment and robotics. Other suppliers are watching to see how the OPC-UA standards shake out and determining whether the Industry 4.0 tools they deploy will be built in-house, contracted out, or a combination of the two.

“Processors say, ‘I need to invest my money and I am so confused about what to buy.’”

Mark Johansen, v.p. marketing & product management at ACS Group, said his company is determining whether it will be easier to integrate another company’s established algorithms, or create its own. In the latter case, companies will have to decide whether to use a subscription model, which could reimagine equipment suppliers as software developers that charge their customers to run the software, the same way Microsoft charges for Windows.

“Manufacturing can be slow to adopt new technologies,” Johansen states. “Part of the issue is putting a value proposition in front of customers. In the short term, equipment costs more; long term, it’s harder to know the full benefits. We have to convince plastics-processing plants that Industry 4.0 is worth their time and money.”

Dri-Air Industries launched a full dryer line at NPE2018 that utilizes the OPC-UA protocol, readying its key product for the future. Jason Sears, v.p. of operations, says that Industry 4.0 was a subject of conversation at the show, with some attendees interested and others having “a long way to go.” Dri-Air is anxiously waiting to see finalized standards for particular product lines, including dryers, but Sears can see the promise of a new, standardized protocol. With the old SPI protocol—RS485—molding machines could talk to auxiliaries. Going forward, using Ethernet connections and OPC-UA, instead of the press “pinging” the entire dryer, however, it can ask for a specific parameter, which marks progress, in Sears’ view.

Italian maker of auxiliary equipment Piovan, which operates in the U.S. via its Universal Dynamics subsidiary, touted an upgrade to UnaDyn’s long-running FACS platform at NPE2018, as well Piovan’s Winfactory OPC-UA supervisory software. Giorgio Santella, Piovan’s chief marketing officer, states that OPC-UA architecture builds flexibility into the system, which customers will need.

“By connecting to Winfactory 4.0, the system has open access to any industry 4.0-compliant equipment or machinery,” states Santella. “That is what our customers are asking about more and more, because you could buy a piece of equipment today and it might not be industry 4.0 compliant; and then you’ll buy equipment tomorrow and it is 4.0 compliant; and the two pieces of equipment can’t speak to each other.”

Piovan also discussed remote assistance at the show. Allowing service technicians to tie into equipment remotely isn’t a new concept; but despite being possible for some time, Santella admits that few processors avail themselves of this amenity out of security concerns. Piovan’s solution with Winfactory 4.0 was to create its own Cloud.

Show attendees had the chance to pepper suppliers with questions about security and the broader impact of Industry 4.0, but as with any paradigm shift, questions remain. “Processors say, ‘I need to invest my money and I am so confused about what to buy,’” Santella said. “They are not confused about performance, but worried about the future possibility of having their equipment in a network like 4.0. The dilemma is big: ‘What should I buy?’”

Related Content

50 Years of Headlines … Almost

I was lucky to get an early look at many of the past half-century’s exciting developments in plastics. Here’s a selection.

Read MoreHow Production Monitoring Can Make You a Better Processor

Real-time information on all your production equipment not only boosts productivity and profitability, but it encourages proactive vs. reactive thinking and sharing of best practices. See how this approach benefited a blow molder with 19 plants.

Read MoreHow Machine Monitoring Delivers Tangible Results

Much more has been said than done about reaping the benefits of data driven manufacturing among plastics processors. Good technology is essential, but change management is the most difficult part of the process. Here’s how to think about both.

Read MoreA Cost Saving Modular Approach to Resin Drying Automation

Whether implementing a moisture-sensing closed-loop system for a single dryer, or automating an entire plant, technology is available to take the guesswork and worry out of resin drying. Using a modular approach allows processors to start simple and build more capabilities over time.

Read MoreRead Next

How Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreProcessor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read More