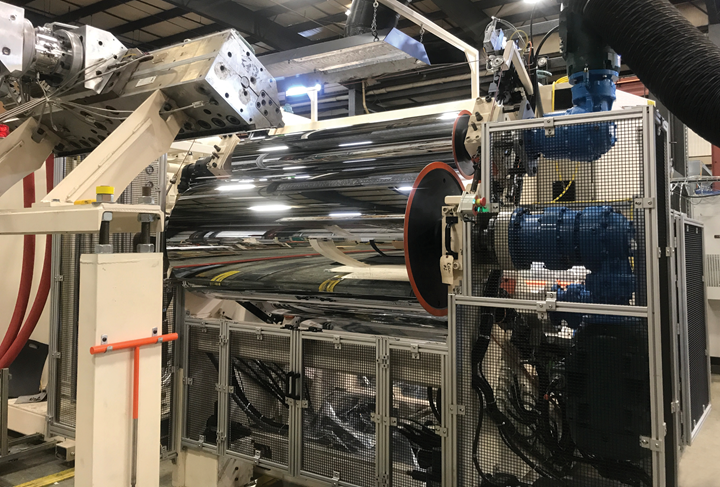

Roll Stand Offers More Automation, Process Control

Processors benefit from technical and bottom line advantages of the roll stand’s inverted-down, multi-roll design.

Applicable for both sheet and cast film, Davis-Standard’s new XP Express-AGT (Active Gravity Touch) roll stand reportedly features greater automation and process control for the full range of sheet (nominal 8 to 60 mil) applications.

Processors benefit from technical and bottom line advantages of the roll stand’s inverted-down, multi-roll design, the machine builder says. This unique arrangement facilitates improved die-nip management and handling, efficient web cooling and conditioning capabilities, precision roll drive control, and high-performance web path options. In addition, the XP Express-AGT addresses low melt strength resin delivery from die slot to nip, and expands the processing of thin gauge sheet.

“The XP Express-AGT is our most versatile and operator-friendly roll stand model yet,” explains Steve DeAngelis, Davis-Standard’s v.p. of sheet and foam. “It builds upon the sustained success of our existing product line to offer more automation and roll control along with smarter ergonomics and a space-saving footprint. This design is also engineered for both sheet and cast extrusion to give processors flexibility to support more applications, especially in rigid and flexible packaging.”

The roll stand is currently available in widths from 36 to 80 in. and with output rates up to 5500 lb/hr. Processors can choose among three AGT roll stand options depending on specific requirements. Each option offers a fully automated multi-roll gap nip, individual roll speed and temperature control, enhanced heat transfer, and an adaptable pull-roll design. This is augmented by four-point Y-axis and traverse X-axis control to further support operator functionality. In addition, uniform cooling on both sides, double polishing capabilities, reduced web stress, and consistent web orientation and thickness control promote high-quality flat sheets with desired clarity.

DeAngelis will be discussing the features and benefits of the stand in a “Tech Talk” presentation during the upcoming PTXPO, March 29-31 at the Donald E. Stephens Convention Center in Rosemont, Ill.

Related Content

-

Die-Lip Adjustment System Relies on Motorized Actuators

Nordson will debut an automated lip adjustment system for its EDI extrusion and fluid-coating dies at the K 2022 trade fair.

-

Davis-Standard to be Systems Integrator for Novel EDI Flat Die

Die uses motorized lip-adjustment, said to be three to five times faster than heated-bolt adjustments.

-

PTi Makes Changes in Leadership Structure

Moves aimed at bolstering the future of the sheet extrusion manufacturer.