Mold Simulation

Simulation Spots Trouble Before It Starts

Blow molding has been one of the slowest processing sectors to adopt simulation software as a design and troubleshooting tool.

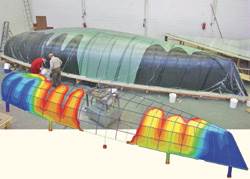

Read MoreNew Software Aids Composite Processing and QC

Several recent software introductions for composites design, processing, and quality control offer more sophisticated predictions of both processability and finished part properties.

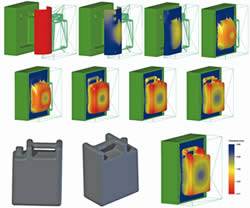

Read MoreBlow Molding Simulation: Ready for Prime Time?

Efforts have been made to simulate the extrusion blow molding process for at least a decade, but actual use has been slow to take hold.

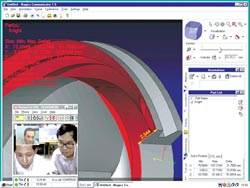

Read MoreMold Designers Put the Web to Work

The internet is redefining the tool-design process. Some mold designers are finding that using the Web to manage a tool project can shorten lead times, cut costs, and make sure vital data get to all participants in a project.

Read MoreNPE 2000 News Wrap-Up: CAD & CAE

NPE 2000 offered a brand-new option for processors and mold designers: the ability to “rent” flow analysis on a pay-per-use basis over the Internet.

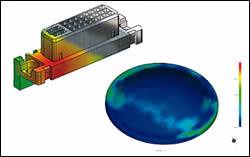

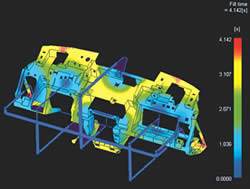

Read MoreThe New Dimension in Mold Simulation

Keep an eye on the increasing prominence of so-called “3D” mold analysis. Two vendors of simulation software from Europe and Asia think it’s the best solution for a big proportion of injection molded parts. Established U.S. suppliers aren’t so sure. In any case, the capabilities of both 3D and standard 2.5D simulation are expanding rapidly.

Read MoreInjection Molding Troubleshooter: Get the Most from Flow Simulation

Flow-simulation software is one of the most powerful tools ever developed for improving injection molded part quality.

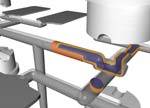

Read MoreComputer Flow Analysis Helps Develop New Profile Dies Faster

Computational fluid dy namics (CFD), or flow analysis, is routinely applied to dies for cast or blown film.

Read MoreNew Runner-Design Concept Boosts Quality & Productivity

Why 'naturally balanced' multi-cavity molds sometimes refuse to fill evenly is a mystery that eluded solution—until now. A simple concept called the MeltFlipper allows molders to increase cavitation and maximize output of quality parts.

Read More