Close-Up On Technology - Interchangeable Dam Adds Versatility to Screw

A new barrier screw has removable keys to change the dam height, allowing the screw to be tuned for highest throughput with resins as different as LLDPE and nylon, says the screw’s designer, Robert Dray, president of R.

A new barrier screw has removable keys to change the dam height, allowing the screw to be tuned for highest throughput with resins as different as LLDPE and nylon, says the screw’s designer, Robert Dray, president of R. Dray Manufacturing. Normally, dam height is changed to improve output by grinding or welding. But with Dray’s screw, removable dams ranging in height from 0.03 to 0.15 in. fit into a slot at the end of the primary channel. “You take one key out and fit another key of a different height into the very tight key-way,” Dray explains. Three screws hold the key in place.

Changing dam height in a barrier screw optimizes the pressure applied to the unmelted material in the screw, compacting the solids bed and forcing solids against the hot barrel wall to speed melting. The dam should compact the solids bed as much as possible without over-compacting it. Over-compacting makes the viscosity too high, so material simply spins in place on the screw, which slows melting, hurts throughput, and causes surging.

Lowering the dam on viscous resins reduces internal pressure and therefore tends to increase throughput and reduce melt temperature. Lowering the dam too much, however, hurts melt quality if gels and other unmelted material pass downstream, and it may reduce output rate because of incomplete compaction of the solids bed.

Dray has built two screws with removable dams: one of 55-mm diam. for a lab extruder, the other a 70-mm model for a Krauss-Maffei injection machine. The injection screw came with five keys from 0.03 to 0.15 in. high. But the customer molds primarily HDPE and so uses almost exclusively the mid-range dam height of 0.09 in. Computerized flow simulations can help a processor select a dam height for highest throughput and best melt quality with a given resin, Dray notes.

What height is best?

Lower dam height works best with higher-viscosity resins and vice versa. The lowest dam height available is 0.03 in., allowing the greatest clearance to the barrel wall. It is appropriate for resins like a 1-MI LLDPE for blown film, Dray explains. The next-lowest dam (0.06 in.) would be suitable for something like a talc-filled, 6-MI polypropylene. The highest dam is 0.15 in., allowing the minimum clearance. This would be used for nylon.

In a coextrusion line for barrier films, removable dams would allow one screw in a satellite extruder to run both EVOH and nylon barrier resins. Or an LLDPE film producer could optimize throughput for formulations with different levels of regrind. LLDPE regrind, for example, has a lower viscosity than the same virgin resin, so a formulation high in regrind would run better with a higher dam.

Removable dams add $100 to $300 to the cost of a barrier screw, depending on size. Removable dams could also be retrofitted onto an existing barrier screw, probably for less than 5% of the screw’s original cost, Dray estimates.

Why not a movable dam?

The removable dam is the latest generation of a screw design that Dray invented and patented in the late 1980s (U.S. Patents #4723847 issued in 1988 and #5,071,255 issued in 1991) for a movable dam at the end of the primary channel. The movable dam is raised and lowered by thousandths of an inch using a hand crank even while the machine is running. It requires a housing on the back of the machine that’s bolted into the sealing mechanism. The movable dam is mechanically more complex and expensive than a set of removable keys, but it offers a complete height range from root diameter to barrel ID. Dray has built over 30 movable-dam screws for extrusion of filled compounds and blown film.

Dray has designed the next generation of movable dam, which will be more fully automatic. “It will sense temperature or pressure variations in the barrier section and adjust the height constantly to minimize those variations,” Dray says.

Related Content

Formulating LLDPE/LDPE Blends For Abuse–Resistant Blown Film

A new study shows how the type and amount of LDPE in blends with LLDPE affect the processing and strength/toughness properties of blown film. Data are shown for both LDPE-rich and LLDPE-rich blends.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreThe Importance of Viscosity in Melting

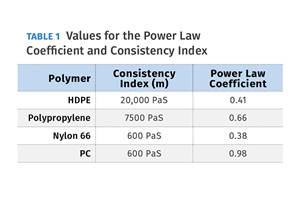

The calculations required to determine the right melt temperature for each polymer are complicated. Knowing the power-law coefficient and the consistency index of the polymer you run might prove useful.

Read MoreHow to Estimate and Control Head Pressure

You rightfully worry about melt temperature, but don’t overlook head pressure, because the two are closely linked and will influence line performance.

Read MoreRead Next

Why (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreAdvanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read More