Dry-Ice Cleaning Pays Off Big For High-Tech Molder

Mold running time has been increased by 200-500% at Performance Plastics.

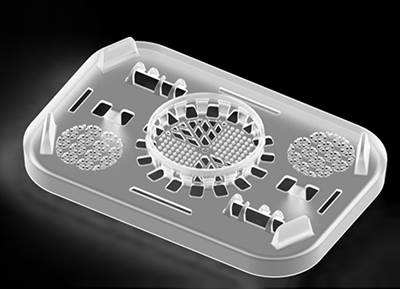

Performance Plastics, Cincinnati, is a custom molder specializing in small, complex precision parts in high-performance engineering materials for the medical-device, energy, aerospace/defense, industrial, electronics, and food/ beverage industries (see July ’12 On-Site feature).

“From design through production, we do what others have dreamed of, failed at, or said can’t be done,” says Tom Mendel, president and CEO. “We are defined not by the industry served, but by the materials we run, the sophisticated tooling we use, and the tight tolerances we hold. We are pushing the envelope here—running 150 mph in a 20-mph zone. We do lots of R&D, lots of engineering, and lots of hard stuff.”

The molder has aggressively lowered its per-part cost with a proprietary, high-volume, direct-gating hot-runner process. The molder has run PEEK since it was first introduced in the early 1980s, and is an approved processor of Torlon (Solvay’s polyamide-imide). Performance Plastics also been involved in development work with LCPs, and is one of the few molders able to run FEP fluoropolymer in eight-cavity, high-volume molds with hot runners.

Keeping the mold clean is a must for any processor. But in Performance Plastics’ case there are two challenges. First, its molds are heated to 450 F, with melt temperatures soaring as high as 800 F. This generates gases that, when liquefied, can stick to the mold—like tar, as Mendel puts it.

Second, when the plastic runs from one end of the part and flows to the end of fill, the gas must be vented through a very precise opening in the mold—one that lets the gas out but does not allow the polymer to escape. This vent at the end of fill gets clogged from the buildup of the volatiles that condense when the mold is cooled. If the tool doesn’t vent properly, problems occur: The gas can destroy the mold material and affect part quality

Mold cleaning usually requires a complete teardown, which is time-consuming and can sometimes result in mold damage due to the cleaning media and solvents involved. But Mendel, acting on the recommendation of a colleague, tested an unfamiliar method: dry-ice blasting with the i3 MicroClean from Cold Jet, LLC, Loveland, Ohio. This dry-ice cleaning system uses non-abrasive pellets or blocks of recycled CO2 that won’t damage mold surfaces or components. The combination of dry-ice blast cleaning’s kinetic energy and thermal effects break the connection between the dirt and mold surface, lifting away contaminants.

Mendel and his team were quickly convinced after the testing phase. Since implementing the Cold Jet solution, Performance Plastics has been able to extend the running life of its molds

by cleaning in the press—including the vent and ejector pins—extending time between complete teardowns.

Mendel states, “I would say that using the Cold Jet cleaning process extends the running time of our molds by 200-500%. It saves us from cooling the mold down, removing it, disassembling it, reassembling it, putting it back in, and heating everything up. That is a lot of time and risk for damage.”

The Cold Jet system has also given Performance a lot of flexibility during mold cleaning. Operators can apply just the right pressure to prevent damage, which is something they could not always do when using solvents and wire brushes. Shutoffs on certain high- pressure molds must be within 0.0004 in.—because at 0.0005 in. the part will flash, and at 0.0002- 0.0003 in. it can’t be vented and will destroy the metal.

Moreover, because a cleaner mold equals a better part, and the molds at Performance can be cleaned quickly while running, the part is vented more effectively. And Performance Plastics now needs only one person to clean the mold, freeing up key personnel for other tasks.

Related Content

Three Key Decisions for an Optimal Ejection System

When determining the best ejection option for a tool, molders must consider the ejector’s surface area, location and style.

Read MoreUsing Data to Pinpoint Cosmetic Defect Causes in Injection Molded Parts

Taking a step back and identifying the root cause of a cosmetic flaw can help molders focus on what corrective actions need to be taken.

Read MoreDiagnosing Defects: Determine True Root Cause Before Adjusting a Process

Common defects can have common causes — flash equals worn mold shutoffs, right? Except when they don’t. Trust your eyes, but verify the root cause before adjusting a process.

Read MorePHA Compound Molded into “World’s First” Biodegradable Bottle Closures

Beyond Plastic and partners have created a certified biodegradable PHA compound that can be injection molded into 38-mm closures in a sub 6-second cycle from a multicavity hot runner tool.

Read MoreRead Next

This Molder Wants Only the Tough Jobs

Need someone to injection mold fluoropolymers, highly filled PEE K, Torlon, or Ultem in complex shapes, tight tolerances, multiple cavities, and high volumes? “We love doing this,” says Tom Mendel, president of Performance Plastics Ltd. (PPL) in Cincinnati. “We’re not for everybody.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More