First PVC Long-Fiber Composites Debut

SolVin has developed technology that allows production of what are said to be the world’s first PVC long- or continuous-fiber composites.

SolVin, the vinyls production unit of the Solvay Group in Brussels, Belgium, has developed technology that allows production of what are said to be the world’s first PVC long- or continuous-fiber composites. The company launched this innovation at the JEC Europe composites show in Paris in March as part of the firm’s sustainable development efforts.

In addition to its mainstay SolVin PVC resins, the company’s latest NanoVin eco-friendly, ready-to-use, aqueous, nanostructured PVC dispersions now can be formulated for long- or continuous-fiber impregnation. Explains Claudine Bloyaert, technical manager, “This breakthrough in formulation of concentrated latex of homopolymer PVC, combined with our advancement in nanotechnology, is the outcome of several years of R&D. This technical combination spearheads our penetration of the composites market, given the fact that we are able to offer extra-thin coatings providing fire retardancy and outstanding stiffness, which cannot be achieved with plastisols.”

CONTINUOUS FLAX OR LONG GLASS

There are two composite technologies for which licenses on process patents are now available from SolVin:

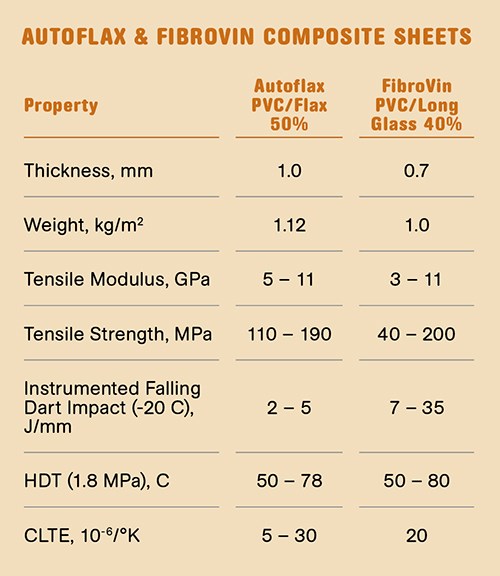

•Autoflax, which consists of rigid consolidated sheets with a thickness range of 0.5 to 4mm, made from 45% to 55% continuous flax fibers in a PVC matrix (SolVin or NanoVin grades). The sheets can be produced by two different processes: Flax fabrics are calendered with several layers of rigid PVC films and then the “sandwich” is heat-compressed at 180 C. Or, flax fabrics are coated with PVC latex and then heat-compressed.

Overall properties and advantages of Autoflax include light weight, thermal insulation, sound proofing, and very good thermoformability. It is also gluable, weldable, and UV-resistant when suitably coated.

Potential applications include automotive interior trim and rear shelves, building door panels, ceiling panels, partition walls, furniture, and marine applications like decorative panels and partition walls. The Autoflax line also could compete with epoxy/flax composites in sporting goods like rackets, as well as furniture and luggage.

•FibroVin consists of sheets from 0.6 to 1.4 mm thick, made of 60% rigid SolVin PVC and 40% long-glass fibers (5 to 10 cm, or 1.95 to 3.9 in.). The production process combines two

technologies, co-developed with Fibroline of Lyon, France: First, dispersion of PVC dryblend into the cut-glass fibers using an electrostatic field (Fibroline); and then gelation of the PVC

dryblend without shearing (SolVin).

Advantages are said to include excellent fire resistance, very high rigidity with high impact strength, very good thermoformability, UV resistance, gluability, and weldability. Potential target applications include electrical boxes, replacing thermoset polyester/fiberglass composites because of the PVC material’s much better weatherability and durability. Other potential uses are facings for sandwich panels in transportation, marine, and building construction, such as partition walls; and as reinforcement for profiles, plates, and pipes.

SolVin says it has achieved good preliminary results in testing the adhesion of flax fibers to PVC, according to Bloyaert. “Yet we are still at the beginning of unlocking the full potential of

PVC in the composites world,” she says. “There is still a broad spectrum of untapped applications for PVC and we aim to seize them.” She notes that SolVin welcomes cooperation from suppliers of kenaf and hemp fibers as alternatives to flax, and from processors interested in expanding into PVC composites. “We will provide ready-to-use PVC dispersions to suit their end-markets and will assist with the composite manufacturing process.”

Solvin is now making its PVC resin grades available in North America. Contact sales export manager Denis Michels in Brussels: email denis.michels@solvay.com; phone +32 22 643 130.

Related Content

A Processor's Perspective: What's Driving Growth in Heavy-Gauge Thermoforming

Key factors for the progress are innovative materials, advanced automation and precision engineering.

Read MoreMaking Gains in the Drain Game

AWD blends extrusion and thermoforming technologies with plenty of home-brewed equipment and processes to keep water away from where it isn’t supposed to be.

Read MoreCompany Begins PET Cap Commercial Production

Origin’s CapFormer System 1 passes site acceptance test and begins commercial production of PET closures.

Read MoreOrigin Materials Unveils CapFormer for Producing PET Caps

Factory acceptance test completed at commercial scale.

Read MoreRead Next

For PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More