Get Materials Processing & Property Data On-Line or Via App

Plastics Technology, Mobile Specs team up to provide molders with processing data.

A lot has happened since I first wrote in this space about MobileSpecs LLC of Laramie, Wyo. In October 2017, I told you about a new app this company had developed that included processing data (up to 25 molding parameters for each material) on more than 20,000 commercially available materials from more than 100 resin producers and distributors. The purpose of this app was to give you a handy source to establish processing parameters on materials with which you might not be familiar.

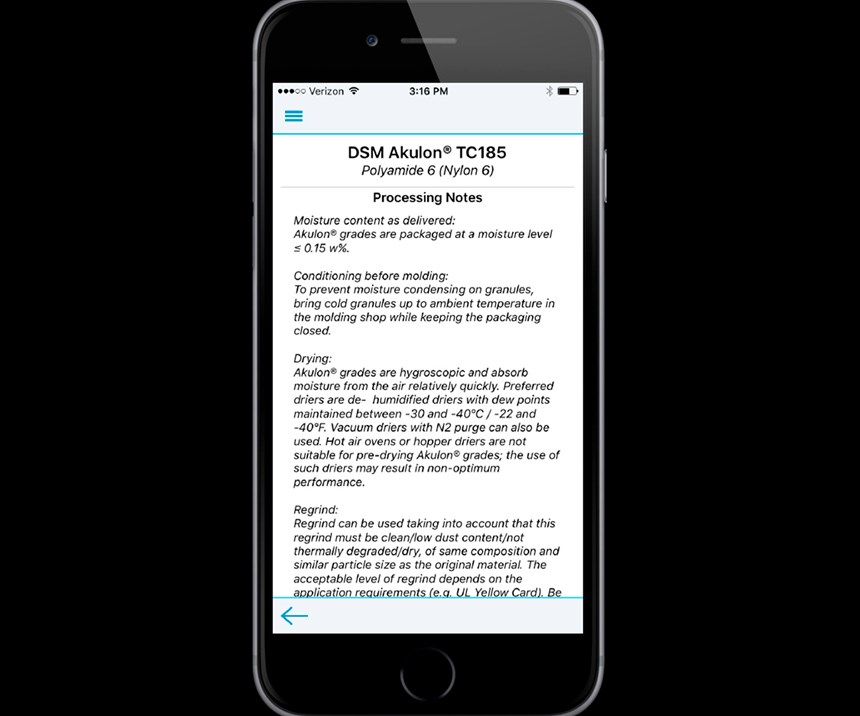

With just a few taps on your mobile device, you’ll find the material you’re looking for and be able to access data for mold shrink, melt flow, recommended processing temperatures, drying parameters, and a bunch more. Detailed text descriptions of each plastic, along with processing notes, provide molders with a great deal of background information about the material they are processing. What’s more, the app offers full supplier processing guides where available.

I also reported that MobileSpecs and Plastics Technology would be working together on making this tool available to molders worldwide. You can download it for free on your Apple or Android phone. It takes seconds to find what you need. You can search for supplier name, generic polymer family, or specific products and grades. The information in the app is continuously updated by Mobile Specs’ engineering team.

MobileSpecs was launched in 2017 by Doug Kenik and Brady Adams. Later, they were joined by Mike Kmetz. Mike was the president and founder of IDES, which developed an online, searchable database called Prospector that contains property information on tens of thousands of materials from suppliers all over the world. And now MobileSpecs is offering—via both the app and mobilespecs.com—complete data sheets on all the 20,000 resins in its database. You can search material by supplier name, product, or grade. Or, you can click or tap on any of the 100 suppliers in the database. From there, you’ll be brought to that supplier’s full list of materials. You can also get access to complete data sheets on each material by registering—for free—using your email address.

This product is resonating with molders. Said Corie Yodis, a project engineer at Epimed, “We run many materials through our processes, which requires us to adjust machine parameters frequently. The app provides us with the processing data we need to quickly adjust machine settings. The centralized database and easy access to the manufacturers suggested processing data allows us to iterate rapidly, which helps efficiency on the floor. MobileSpecs is also great at responding to customer inquiries and feature requests; recently they added a great feature that allows me to save all of the resins that we commonly use as favorites. The new functionality makes it even quicker and easier to retrieve the processing information I need and tailor the app to my personal uses.” Added John Parker, a senior process engineer at Cosmo Corp., “My first look was a KR01 (Ineos Styrenics’ K-Resin SBC), and the MobileSpecs app and desktop version blew me away with not only the parameters but a lengthy breakdown of specifics and cause-and-effect situations.”

Have you checked out mobilespecs.com or downloaded the app yet? No reason to wait. Give it a whirl.

Related Content

Understanding the ‘Science’ of Color

And as with all sciences, there are fundamentals that must be considered to do color right. Here’s a helpful start.

Read MoreMelt Flow Rate Testing–Part 1

Though often criticized, MFR is a very good gauge of the relative average molecular weight of the polymer. Since molecular weight (MW) is the driving force behind performance in polymers, it turns out to be a very useful number.

Read MoreThe Effects of Time on Polymers

Last month we briefly discussed the influence of temperature on the mechanical properties of polymers and reviewed some of the structural considerations that govern these effects.

Read MoreThe Importance of Melt & Mold Temperature

Molders should realize how significantly process conditions can influence the final properties of the part.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read More