Get to Know Your Gravimetric Blender

The introduction of gravimetric blending technology has impacted virtually every corner of plastics processing. Here's what you need to know to keep them operating at their best.

The development about 25 years ago of self-calibrating, repeatable gravimetric blenders solved a lot of problems. The volumetric units that prevailed before then were fairly accurate, but they all relied on timers and motor speeds for control. This made it impossible for processors to determine whether or not the ingredient had indeed been delivered to the machine at the desired rate.

The old-style units were also difficult to calibrate, and it was impossible to recognize and correct for changes in material characteristics. Problems with screw blockages, varying material particle size and density, and material bridging in feed hoppers caused processors serious quality problems. Calibration, repeatability, accuracy, verification … volumetric blenders could not effectively address any of these. If a processor was working with color, there were regular struggles with quality control. Too much color? Not enough? It was a guessing game, and the processor really never knew what was or wasn’t happening in the blending system until it was too late.

What if the processor were able to weigh each ingredient? That would give validation of material dispensed, better blend accuracies, and process confirmation. That idea gave birth to the concept of gravimetric blending. Numerous patents were issued, and in 1989 processors could buy a self-calibrating, repeatable gravimetric blender that cost about the same as the volumetric systems it would soon displace.

The impact has been phenomenal—from 50 units in the first year to thousands this year in North America alone. The introduction of gravimetric blending technology has impacted virtually every corner of plastics processing. Gravimetric blenders are now offered by virtually every conveying system manufacturer as part of a complete package.

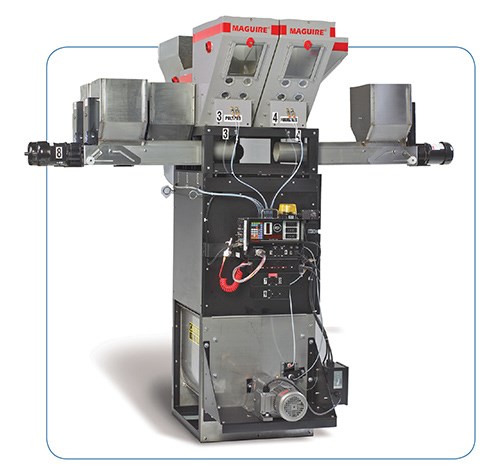

The first-generation gravimetric blenders were designed to be mounted on injection presses, could handle three components, and had a capacity of 400 lb/hr. Most all of today’s suppliers are offering blenders that handle six or more ingredients at capacities of up to 12,000 lb/hr or more for both injection and extrusion applications.

ACCURACY: MORE THAN A SCALE

The most critical part of any gravimetric blender is the weighing package. This is much more than just a weigh scale—it is made up of three primary components: the material feeding systems, which dispense the individual ingredients; the weigh bin, which catches and weighs the material; and the control system, which monitors, adjusts, calibrates, and controls the other two. The right combination of these three is the first step to success in gravimetric blending.

Claims regarding accuracy for gravimetric blending vary considerably and can be quite confusing. They range from 0.1% of metered material, to a percentage of the ratio of each material that is been added to a base resin, to a batch-to-batch accuracy spec. Many suppliers make claims relative to the accuracy of each dispensed ingredient. That can get pretty tricky.

For example, if you have a 1-kg batch and you want 4% of that to be a color, stabilizer, or other additive, you will need 40 grams of the additive. If the target accuracy is ±0.5% of the individual ingredient, you’ll want the metering device to meter and weigh the 40 grams at an accuracy of ± 0.2 grams of the additive. One gram of color contains about 40 individual pellets, so the target accuracy is ±8 pellets.

The point is, a couple of pellets can mean a lot, and the proper feed device is critical. One rotation of a screw flight in an auger feeder, or a fraction of a second in a slide-gate or disc feeder, and you have missed your target. A four-pellet miss can quickly turn into disaster if not caught and corrected. Nobody is actually counting pellets, so the system has to constantly adjust up or down, based on the weight it measures of the ingredient dispensed.

The critical point is that the processing machine needs to see the same ratios, within a certain acceptable accuracy range, time after time, batch after batch. Errors in feed accuracies must be recognized and feed devices automatically recalibrated to meet targets.

Numerous other conditions can impact the accuracy of the feed system. Material should be very uniform in particle size and either free-flowing or conditioned in order to provide a uniform head pressure over the feed device. The lack of a consistent head pressure can seriously affect the flow of the material to the feeder and impact accuracy. Irregular regrinds and powdered additives are the major culprits here.

Most suppliers offer a variety of flow enhancers to minimize bridging problems and ensure head pressure and a consistent flow to the feeder. Vibrators are often recommended—but be careful, as they can tend to compact the material and compound the problem. Aeration also poses a unique set of problems, as some materials have drastic changes in flow characteristics when aerated. Often the best flow enhancer is simple bridge breaker or some type of mechanical agitation.

There are about as many feed devices for primary and additive materials available as there manufacturers of blenders. You have slide gates, plunger valves, discs, pinch valves, vee ports, and screw feeders, to name a few. All have their strengths and weaknesses. Keep it simple and remember that many materials are going to need preconditioning before they can be dispensed.

Load-cell accuracy can be affected by external forces, such as vibration. The software of the system has to “tune out” the normal vibrations of the machine and accurately detect weights as ingredients are being dispensed. This is not an easy thing to achieve, and some software engineers are still wrestling with it.

An effective gravimetric blending system goes way beyond feeders, scales, and mixers. In the end it becomes a small process of its own—a process requiring storage, metering, weighing, blending, and process control. And, like most processes, it is only as strong as its weakest component.

When you need to blend dry material, you have another thing to worry about: moisture regain. Some hygroscopic materials are more prone to moisture pickup than others, particularly in the presence of regrind. Blanketing a blender with dry air at an appropriate temperature is often sufficient to keep material dry. But -40° dewpoints are not necessary. Remember, you are not trying to redry the material, just keep it from picking up moisture.

A dry-air generator, which will take the ambient dewpoint and drop it by 30- 40° is usually more than sufficient. Since the material is already dry, a closed-loop dehumidifying dryer should not be required. When “blanketing” a blender, it needs to be properly sealed and designed to withstand the appropriate dry air temperature. Several suppliers offer blenders that can be blanketed with dry air.

WHERE TO MOUNT IT?

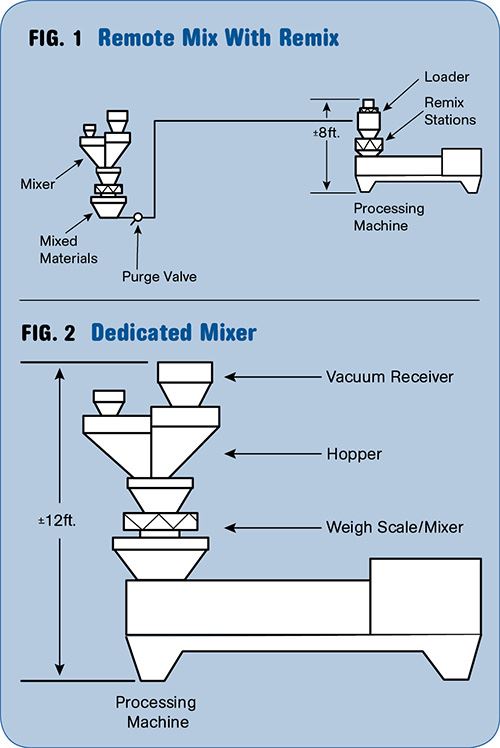

Historically, blenders—like dryers—have been mounted right on the processing machine. But, equipment stack-ups, frequent color changes, maintenance complications, cumbersome access platforms, and lost machine time have caused plant personnel to rethink this approach. Some processors are blending off-line, then conveying the material to the process. But variations in particle size, density, and flow characteristics can easily lead to material separation during the “at-rest” time of a typical vacuum-conveying cycle. When the normal cycle is completed and the material is stopped, some particles will continue to roll due to the variations mentioned above, resulting in separation or “demixing.”

A new approach meters, weighs, and blends the material at proper ratios at a location remote from the processing machine. Then complete blended batches are conveyed to the machine(s)—not by a traditional vacuum setup but via a system that has an integrated purging line (see illustration). With a purge system, a discrete, blended “batch” is conveyed, and proper blend ratios are maintained.

The receiving station at the machine consists of a vacuum receiver and a mixer, forming a “remix station.” When the batch arrives it is remixed and the material is ready to be processed. The results of conveying in a discrete batch and then remixing can impact efficiency and investment and operating costs.

You will also minimize material inventory at the machine, speed up color and material changes, gain machine uptime, reduce clutter around the machine, and eliminate the need for expensive access platforms. With this scenario, integration with the conveying system is critical, and blenders can be dedicated to colors and blends rather than machines.

New applications are constantly presenting challenges to blender suppliers. Materials like wood flour, fine chemical additives, and irregular regrinds present a whole new set of challenges in the areas of storing, feeding, blending, and controls. Designs to handle bridging, density variations, flowability, and explosion hazards are all on the plate of machine builders.

In the future, processors are going to be asked to confirm just how, where, and when their product was processed. Your suppliers will be designing systems that trace the material from gaylord or drum to finished part. Keep an eye peeled for these developments.

Related Content

Formulating LLDPE/LDPE Blends For Abuse–Resistant Blown Film

A new study shows how the type and amount of LDPE in blends with LLDPE affect the processing and strength/toughness properties of blown film. Data are shown for both LDPE-rich and LLDPE-rich blends.

Read MoreHow to Get Rid of Bubbles in Injection Molding

First find out if they are the result of trapped gas or a vacuum void. Then follow these steps to get rid of them.

Read MoreImprove The Cooling Performance Of Your Molds

Need to figure out your mold-cooling energy requirements for the various polymers you run? What about sizing cooling circuits so they provide adequate cooling capacity? Learn the tricks of the trade here.

Read MoreSolve Four Common Problems in PET Stretch-Blow Molding

Here’s a quick guide to fixing four nettlesome problems in processing PET bottles.

Read MoreRead Next

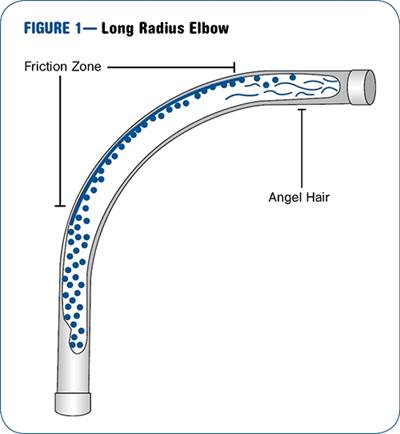

Avoid Those Devilish ‘Angel Hairs’

Angel hairs wreak havoc on plastics processing: clogging filters, plugging conveying lines, causing feed problems at the blender, and jamming up machine throats. Here's how to prevent their formation.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read More (2).jpg;maxWidth=970;quality=90)

(2).jpg;maxWidth=300;quality=90)

(1).jpg;maxWidth=970;quality=90)