NPE

PT, MMT Announce Leadership Changes

Jeff Sloan is named brand manager of PT; Dale Jackman assumes same role for MMT. Tony Deligio to succeed Jim Callari as head of PT’s editorial efforts.

Kick Back at the Beer Garden (and Other Places to Recharge)

Need to recharge after a productive visit to the show floor? Find the perfect spot here.

Read MoreItalian Machine Builders Bandera, Macchi Running Film Lines

Five layer lines running all polyethylene as part of sustainability push.

Read MorePiovanGroup Announces Transition In Leadership In North America

John Erkert ascends to Regional CEO position for North America as industry veteran Kirk Winstead retires.

Read MoreGet Ready to Be Blown Away With New Extrusion Technology

Don't miss out on the ultimate showcase of cutting-edge extrusion technology at NPE. Explore the latest in extrusion technology, live from the show floor.

Read MoreInfrastructure May Prove Big Landing Spot for Recycled Plastics

As the government funds infrastructure improvements, a hot topic at NPE2024 – exploration of the role recycled plastics can play in upcoming projects, particularly road development.

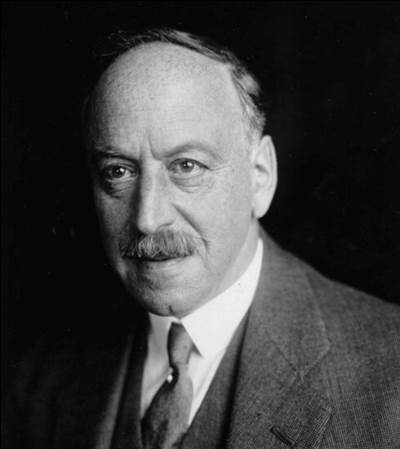

Read MoreInnovator in Polymer Science and Education: Dr. Joseph A. Biesenberger

NPE2024: Dr. Joseph A. Biesenberger, a pioneer in polymer science and education, was inducted into the Plastics Hall of Fame in 2024. From founding the Polymer Processing Institute to seminal works in reactive polymer processing, his impact continues to shape the plastics industry.

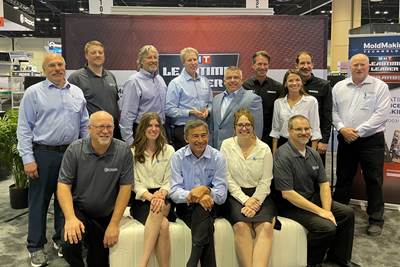

Read MoreDynamic Tool Corp. Wins MoldMaking Technology’s 2024 Leadtime Leader Award

Dynamic Tool Corp., a provider of engineered tooling solutions based in Menomonee, Wisconsin, has been awarded MoldMaking Technology’s prestigious 2024 Leadtime Leader Award. The announcement was made during a live awards ceremony at the Plastics Technology booth, where owners Steve and Ken Eberle accepted the award on behalf of their team.

Christina Fuges

Editorial Director, MoldMaking Technology

NPE2024: 10 Things to Do in Orlando

Orlando has a variety of attractions and experiences on offer for those who want to do some sight seeing during NPE2024.

Read MoreIn the Zone: Recycling & Sustainability

The Recycling & Sustainability Zone is the place to learn about new technologies and strategies for a greener plastics economy.

Read MoreChihiro Kanagawa: PVC Pioneer and Environmental Steward

Follow the legacy of Chihiro Kanagawa, a pioneer in the PVC industry and advocate for sustainable growth. Chairman of Shintech, his vision transformed PVC manufacturing.

Read MoreSpark Stages Bring Education to NPE2024 Show Floor

Three stages, five days of programming and more than 75 sessions — the all-new Spark Stages at NPE2024 give attendees a chance to rest their feet and exercise their minds.

Read MoreLuigi Bandera: Pioneer of Plastic Extrusion With Vision

NPE2024: Get to know the life and legacy of Luigi Bandera, the visionary behind Costruzioni Meccaniche Luigi Bandera, who revolutionized plastic extrusion technology and earned a place in the Plastics Hall of Fame in 2024.

Read MoreSee a 7-Layer Stretch Line Controlled by AI

Colines producing high-tech stretch film on a line with an artificial intelligence control package.

Read MoreArthur Eichengrün: Pioneer of Cellulose Acetate Manufacturing Processes

Explore the legacy of Arthur Eichengrün, a trailblazer in 20th-century chemistry and materials science, whose achievements reshaped both medicine and the plastics industry. His groundbreaking contributions led to his induction into the prestigious Plastics Hall of Fame in 2024.

Marcela Castro

Editora Asociada

Beyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreStreamlined Drying Process Speeds Up Changeovers

NPE2024: Maguire demonstrating increase in productivity possible by vacuum drying.

Read MoreProgram Provides Equipment Maintenance, Overhauls and Upgrades

NPE2024: Program aims to ensure equipment remains at peak performance levels throughout its life cycle.

Read MoreUnveiling the Next Generation of Injection Molding Machines: Faster, Smarter, and More Efficient

Get ready to revolutionize your manufacturing process with cutting-edge injection molding technologies that promise to streamline production and maximize output. See what our editors are noticing on the show floor.

Read MoreAlpine Is Focusing on Efficiency, Sustainability, While Pushing for Better Recycling Infrastructure

NPE2024: New technology aims at improving efficiencies in film production, but executive calls on e-commerce retailers to help develop packaging infrastructure.

Read MoreHonoring Excellence at NPE 2024: Plastics Hall of Fame

Yesterday, the Plastics Hall of Fame celebrated a legacy of innovation and vision for the plastics sector with 17 new members. Discover how these pioneers have helped shape the future of plastics.

Read MoreThe Titanium Man: Arthur P. Haag's Legacy in Plastics Innovation

Learn about Arthur P. Haag, the visionary behind purity titanium catalysts, whose innovations revolutionized plastics manufacturing for decades. He was inducted into the Plastics Hall of Fame in 2024.

Marcela Castro

Editora Asociada

For PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MorePET Cap and Closure Manufacturing System Launches

NPE2024: Origin Materials and partner Packsys Global say the high-throughput system opens the door to monomaterial bottles, promoting recycling and easing end of life for the package.

Read MoreA Party Six Years in the Making

For the first time ever, NPE opens with a reception for attendees. Join the party tonight in the Valencia Ballroom.

Read MoreNPE2024 Features Medical Industry Sessions

Learn about trends in sustainability, materials, collaboration and more at the NPE2024 Medical Industry Sessions.

Read MoreInside the Florida Recycler Taking on NPE’s 100% Scrap Reuse Goal

Hundreds of tons of demonstration products will be created this week. Commercial Plastics Recycling is striving to recycle ALL of it.

Read MoreIndustry Experts Offer Insights at NPE2024 Packaging Sessions

Learn from industry experts about the latest trends and innovations in packaging at the NPE2024 Packaging Industry Sessions

Read More

(2).jpg;maxWidth=300;quality=90)