New Process Combinations Extend Injection Molding's Capabilities

A new tooling and process concept that seeks better control over multi-cavity molding, and another that achieves new capabilities with novel blends of multiple process technologies were themes presented in papers at the 22nd Colloquium held by the Institute of Plastics Processing (IKV) in Aachen, Germany.

A new tooling and process concept that seeks better control over multi-cavity molding, and another that achieves new capabilities with novel blends of multiple process technologies were themes presented in papers at the 22nd Colloquium held by the Institute of Plastics Processing (IKV) in Aachen, Germany. The IKV is a world-famous plastics research institute that focuses on molding and tooling.

‘Injection transfer’

Better quality and uniformity in multi-cavity molding of small thermoplastic parts is the goal of a new process called Injection Transfer Molding (ITM). This adaptation of thermoset transfer molding can be described as a combination of injection-compression with hot-runner molding.

Tobias Pfefferkorn, researcher in injection molding and mold technology at IKV, says conventional hot-runner injection molding is subject to unequal temperatures and pressures of melt entering multiple cavities. These differences can mean different viscosities and filling and cooling profiles, resulting in parts with different dimensions and properties.

Pfefferkorn says another limitation of conventional injection tooling is that a hot-runner system tends to be designed for optimum performance with a particular mold and material and may not work as well in a totally different application.

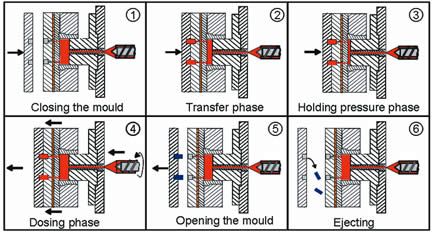

IKV developed a mold with a special electrically heated hot half on the stationary side of the mold (see diagram). The hot half has a melt-transfer chamber that stores the melt from the screw and then transfers the melt into the mold cavity by means of a piston/cylinder system.

The cold half of the mold is on the moving-platen side. Heat transfer between the hot and cold halves is reduced by an insulating plate in the stationary half. When the mold parting line closes, the piston/cylinder compresses the melt-transfer chamber, pushing material through the short gate directly into the mold cavity. In one sense, it resembles two-stage injection with the melt accumulator or shooting pot built into the mold. In this system, injection and holding pressure is provided by the mold, not the screw, which remains stationary.

After the holding-pressure phase, the transfer chamber is filled with material for the next cycle. The main parting line, which moves independent of the transfer chamber’s actions, remains closed until the part is sufficiently cooled.

A number of benefits are said to result. The melt-transfer part of the mold is independent of part geometry and need not be changed for different applications. Injection volume is determined by the movement of this chamber. Using different cavity inserts would reduce the total cost of multiple molds. Expensive hot-runner temperature controls also are no longer needed. And due to the short melt path and direct gating from the chamber to the cavities, all cavities are filled equally using lower pressures than would be possible with conventional hot runners. Less shear and stress are imparted to the melt, Pfefferkorn claims, creating parts with low shrinkage and warpage. Low shear can be advantageous for molding long-glass reinforcements or ceramic-powder compounds. IKV will soon test the process in a production mold with more than 100 cavities. IKV has already achieved successful results using polypropylene with long-glass fibers and in molding up to 12 cavities.

Melding multiple processes

Ultra-thin-wall parts and glass-filled hollow parts with a smooth inner surface are applications on the cutting edge of molding today. To get there, molders use processes such as sandwich molding, injection-compression molding, and gas or water assist. While these advanced processes today are usually used separately, combinations of these techniques can achieve more sophisticated parts, reduce costs, or overcome limitations of individual methods, says Christoph Lettowsky, researcher in multi-component injection molding at IKV.

Lettowsky evaluated process combinations of sandwich molding with injection-compression and fluid-assist molding. The combinations all start with forming the skin-core-skin sandwich structure in the mold.

“Combining sandwich molding with injection-compression yields parts with a more uniform core and skin distribution,” says Lettowsky. “The lower injection and filling pressures and the even compression of the material during the compression process combine to give a low level of material orientation to the part. This can result in reduced shrinkage and distortion.” It can also reduce cavity-pressure requirements, since the mold is “open” during filling.

In addition, the compression step allows users to achieve thinner skins and thinner walls overall. “Sandwich-with-compression molding can produce thin-wall parts that cannot be produced with conventional molding,” says Lettowsky. “With conventional sandwich injection molding, a wall of 1.5 mm was the thinnest we realized, while the test part made with the sand wich/compression process yielded a 1-mm wall.” On the other hand, he notes that conventional sandwich molding allows a user to realize a larger percentage of core material in the part.

A combination of sandwich molding and water-assist molding was also tested in molding an arm rest of long-glass PP and unfilled PP. Molders had previously found that using water injection to core out fiber-reinforced materials such as short-glass reinforced nylon 66 or long-glass PP resulted in poor quality of the inner surface and dimensional deviations of the hollow void in the part. “The flow characteristics of the glass-filled resins made water-assist processing difficult or impossible,” says Lettowsky.

He devised a test utilizing a sandwich of 30% long-glass reinforced PP skins over an unfilled PP core. The armrest mold is 30 mm diam. and 500 mm long. When the water was injected, it cored out just the unfilled material. Thus the outer layer provided rigidity, toughness, and tensile and burst strengths, while the inner layer had good barrier properties and a smooth inner surface. (The validity of this approach has been confirmed by other sources using it in commercial production. See Learn More box.)

Related Content

Completely Connected Molding

NPE2024: Medical, inmold labeling, core-back molding and Industry 4.0 technologies on display at Shibaura’s booth.

Read MoreInternal Gas Pressure Molding Offers Sustainability Benefits

Wittmann Battenfeld says its upgraded Airmould 4.0 technology, which features a more compact footprint, saves material and cycle time — thereby also cutting energy use.

Read MoreStructural Foam Injection Molding Line Extended

At K 2022, Wilmington Machinery introduced the dual-injection Lumina MP1200 medium pressure molding machine.

Read MoreFakuma 2023: Wittmann Battenfeld Expands All-Electric Line, Direct-Current Capabilities

Wittmann Battenfeld will introduce the new EcoPower B8X injection molding machine line and show direct current as an energy source for a concept machine that will power its own robot.

Read MoreRead Next

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More