Quantifying the Appearance of Plastics

Sponsored ContentGloss, reflection haze, and transmission haze are three of the most prevalent effects on the appearance of plastics. With the help of multifunctional tools like gloss meters and spectrophotometers manufacturers can measure these visual affects to ensure the integrity of a products appearance from start to end.

Share

Read Next

Many things affect the appearance of plastics. Here, we will discuss three of the most prevalent: Gloss, Reflection Haze, and Transmission Haze.

Gloss

Many people think they know what “gloss” is but ask five different people and you are going to get five cloudy answers. Considered as important as color, gloss is an aspect of the visual perception of objects that has a psychological impact of products on a consumer. So, what is gloss then? Defined as ‘The attribute of surfaces that causes them to have shiny or lustrous, metallic appearance.’ The real difference between a shiny, smooth surface and a rough matte one comes down to the amount of gloss.

The use of gloss enhances the design of this game controller.

Gloss is a major contributing factor to overall visual appearance, so much that many plastic manufacturers create unique gloss designs to differentiate their products in the eyes of the consumer. Since gloss give such impression, many plastic products have unique design to differentiate themselves. Automotive interior parts such as dashboard have texture design, giving uniqueness to the car model and imparting a luxury feeling. Many appliances around us use plastic and gloss as is important factor when designing a product and product quality evaluation in production.

Gloss is not just an enhancer to appearance; uncontrolled gloss levels can be the difference between a good product and scrap. A common issue manufacturers’ face when making molded products involves gloss levels. Even when using the same resin and colorants, the molding process itself can often result in different gloss levels throughout a product’s surface, drastically changing the look and “feel” of the plastic. Since gloss has a large impact (negative or positive) on appearance, it is common practice to evaluate a product’s production quality using gloss as the main criteria. Accurate gloss measurement is a key component when Establishing a Quality Process for Product Color Consistency.

Proper Gloss Measurement

Historically speaking, gloss measurement is the most widely used evaluation for surface appearance quality. Done with an instrument known as a Gloss Meter, by measuring specular reflection. Specular reflection has a direct relationship between the ratios of incident light and reflected light. In other words, the device measures gloss by presenting a continuous beam of light, at a fixed angle, on to the surface, and then gaging the amount of reflected light from that same angle displaying the output in Gloss Units, or GU. Traditionally, Gloss Meters come with one or more angles of measurement (20-degree, 60-degree, and 85-degree) to give the user the accuracy they need. The 60-degree angle (also known as the “Universal Angle”) is best to determine which angle to use.

Selecting Gloss Measurement Angles

| Gloss Range | 60° Value | Notes |

| High Gloss | >70 GU | If the measurement exceeds 70 GU, 20° measurement is recommended |

| Medium Gloss | 10-70 GU | 60° measurement is recommended |

| Low Gloss | <10 GU | If measurement is less than 10 GU, 85° measurement is recommended |

After measuring, it is possible that two samples with similar gloss values can still look different. The sections below discuss them, and their effects on appearance.

Haze

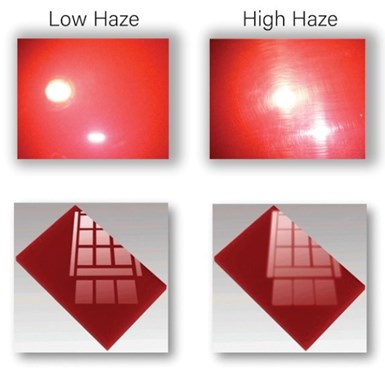

Words like foggy or cloudy are often associated with Haze and are vague and hard to define. This is because depending on an object’s transparency, haze can be referring to one of two different qualities, Reflection Haze or Transmission Haze.

Measuring the color, gloss, and haze of plastics

Reflection Haze

Ideally, the reflection from a high gloss surface should be clear and radiant, however, due to faults in the surface reflections can appear milky or hazy.

Reflection haze is an optical phenomenon usually associated with high gloss surfaces, it is a common surface imperfection that reduces appearance quality and is characterized as “a surface in which reflections are visibly shallower with a milky finish, in addition halos are often visible”.

Ideally, the reflection from a high gloss surface should be clear and radiant, however, due to scattering and faults in the surface caused by microscopic structures or textures (≈ 0.01 mm wavelength) reflections can appear milky or hazy reducing the quality of its overall visual appearance.

Reflection haze meters are traditionally used to measure reflection haze and use a standard glossmeter design with additional detectors 2º either side of the specular angle to measure the haze component. In addition to gloss evaluation, reflection haze provides a further analysis of appearance.

Transmission Haze

Transmission Haze occurs when light passes through a transparent plastic material and creates an unfocused or blurry appearance of the objects behind it.

Transmission Haze occurs when light passes through a transparent plastic material and creates an unfocused or blurry appearance of the objects behind it. Have you ever look at a plastic folder and not been able to read the text on the paper inside of it? That is because of transmission haze.

Use a transmission spectrophotometer for process control when haze is problematic in transparent materials, such as plastic bottles and films. Spectrophotometers, often used in conjunction with QC analysis software, generate comprehensive data on the clarity of the material and the amount of haze in its appearance. This allows users to pinpoint the origin of the haze and take corrective action before a bulk production run happens and documented for future batches.

Some industries have regulations for the haze of a product, making haze not just important to the design but essential to the product itself. For example, face shields used as personal protection equipment in the medical field need to have a haze value of 2% or less. As haze approaches 30%, it becomes more opaque/translucent and it no longer considered a transparent object.

Measuring Haze using a bench-top Spectrophotometer

The use of a spectrophotometer can measure haze on plastic products such as a water cooler.

Color measurement is a science and like any other science, it is critical to eliminate as many variables as possible.

Use the following haze measurement instructions for benchtop spectrophotometers in such a way as to identify haze as a variable. Place the plastics sample in the transmission measurement chamber of the spectrophotometer, and take a measurement per proper protocol, and following any prompts from the software. Record your results if comparing two samples against each other. The first one is Target and the next as a Sample, with any differences displayed and accepted or reworked as needed. Spectrophotometers can provide the benefit of outputting both color and haze data. On the other hand, there are haze meters available, which solely serve for haze measurement. Due to optical geometry differences, haze data from both instruments may show differences by samples. If using both instruments in combination in a working environment, we recommend you compare the data and develop the coefficient to read the data in the same way.

Summary

While it is somewhat easy for the human eye to visualize the appearance of plastic, it is difficult to communicate what is seen efficiently. With the help of multifunctional tools like Gloss meters and spectrophotometers, manufactures can effectively quantify the visual representation of gloss, and reflection haze. Being able to quantify the appearance of plastics with these instruments allow developers to attach actual values to their designs. QC Managers can then monitor these metrics during the production cycle to assure the integrity of the appearance from start to end, reducing rework, and saving time and materials.

For a more comprehensive look into measuring Gloss, Reflection Haze, and Transmission Haze we recommend downloading the whitepaper Understanding Gloss with the Rhopoint IQ-S it is a virtual guide to gloss measurement.