Raising Interest Rates and Rising Inflation

From a policy-making perspective, the U.S. economy has entered into a vexing phase of the current business cycle.

From a policy-making perspective, the U.S. economy has entered into a vexing phase of the current business cycle. The Federal Reserve Board has a mandate to keep the overall rate of inflation at acceptable levels, and its best instrument for doing so is by adjusting the interest rate at which it lends money to banks. As everyone knows, the Fed has been gradually raising interest rates for well over a year in an effort to keep a lid on inflation while at the same time keeping the GDP expanding at a healthy rate.

The good news for plastics processors as well as their customers and suppliers is that so far the rising interest rates have not resulted in a decrease in demand for manufactured products or a recession in the overall economy. In fact, the best estimates for the overall GDP growth in the first quarter of 2006 are in the range of 4% to 5% and this will include higher-than-average growth in spending for capital equipment and durable goods. The bad news is that this rate of overall growth is well above the long-term potential for the U.S. economy, and if it persists, it will ultimately cause accelerating inflation. And unfortunately, there is strong evidence that inflation is currently at the top of the Fed's target range, and the upward pressure is increasing.

The core Consumer Price Index (CPI), which excludes the volatile food and energy categories, is expanding at an annual rate of a little over 2%. The target range for this indicator is between 1.5% and 2.5%. Another measure of inflation is the core Consumer Expenditure Deflator, and this indicator is also expanding by 2% but here the target range is 1% to 2%. So both of these indicators are still within the acceptable range, but they are nearing the top and the recent trends are clearly rising.

The forecast for future levels of inflation is based on the economic conditions that presently prevail, and here there is cause for concern. Commodity prices are quite high and are threatening to go even higher. Everyone knows about the elevated prices of petroleum products and natural gas, but important commodities such as copper and other metals are also quite high. The high prices of these commodities have yet to affect the overall rate of inflation, but they remain a threat to contribute to higher prices for finished goods in the future.

The decline of the dollar when compared with the currencies of our trading partners is also a source of inflationary pressure. This puts upward pressure on import prices, and could really become a problem if the Chinese allow the value of the yuan to continue to rise as they are expected to do. A lower currency value for the U.S. would not be such a problem if we exported more than we import, but that is far from the case, therefore a rise in the cost of imports will produce significant pressure on overall inflation. For U.S. plastics processors, this mitigates many of the benefits that would otherwise result from a higher value for the Chinese currency.

In recent months, processors have responded to the spiking costs of energy and materials by investing in more efficient and productive equipment. This will still be a viable strategy for some segments of the industry, but the overall productivity growth in the industry will likely decelerate for the foreseeable future. The rising capacity utilization rates combined with the increasing shortage of skilled workers in the plastics and other industries will mean that manufacturers will have to pay an increasing amount for incremental gains in output. In other words, most of the inexpensive solutions are no longer available, and now businesses will be forced to pay more. Increasingly, these rising costs will be passed on to the customers through higher prices, and this will contribute to a rising rate of overall inflation.

So policy makers must find a balance point in the economy where productivity gains are sufficient to offset the growth in consumption. They must not allow the economy to grow too quickly, but they do not want to stifle growth altogether. This job is made even more difficult because the economy's response to rising interest rates is non-linear. A series of small increases could appear to have little or no effect on economic growth (similar to the current situation), and then all of a sudden, the equities markets could get spooked, consumers and businesses could become nervous, and the whole economy could start into a recessionary spiral. This has not happened yet, and there is a good chance that it will not. But it is possible that events will force the Fed to become more aggressive in its efforts to halt inflation, and this will likely be detrimental to the short-term prospects for U.S. manufacturers.

Related Content

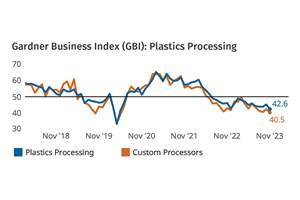

Plastics Processing Activity Drops in November

The drop in plastics activity appears to be driven by a return to accelerated contraction for three closely connected components — new orders, production and backlog.

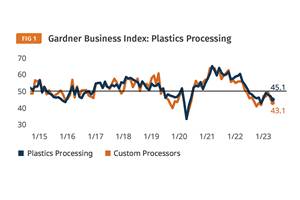

Read MorePlastics Processing Contraction Continues

Contraction dominated the GBI index for overall plastics processing activity and almost all components, collectively suggesting a slowdown.

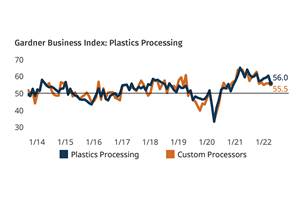

Read MorePlastics Processing’s Ups and Downs

Overall index dips, but custom processors hold steady. Employment up, backlogs down.

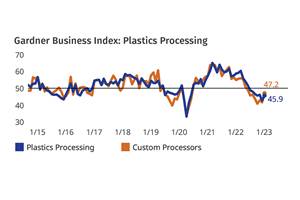

Read MoreProcessing Activity Contracts More Slowly in January

Despite contracting again in January, plastics processing activity rebounded a bit from a rather significant drop in December.

Read MoreRead Next

Beyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE 2024.

Read MoreRecycling Partners Collaborate to Eliminate Production Scrap Waste at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair will seek to recover and recycle 100% of the parts produced at the show.

Read More

.png;maxWidth=300;quality=90)