Tracing the History of Polymeric Materials -- Part 29: Polyurethane

This material family has unparalleled versatility, not only in terms of the forms the material can take, but in the different ways in which it can be processed.

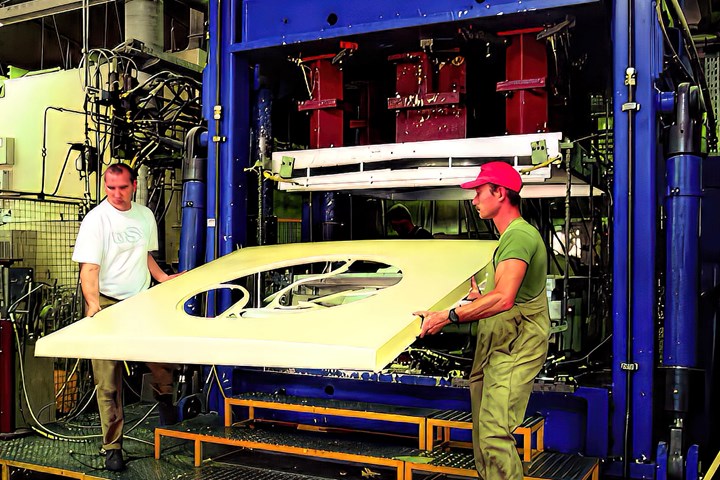

Versatility of polyurethanes: (1) Molded flexible foam cushioning for an automotive IP. (Photo: Covestro)

In the same era when Wallace Carothers was conducting his experiments to synthesize polyesters and nylon at DuPont, a German chemist, Otto Bayer, was investigating another type of reaction using some of the same chemistry, but introducing a new constituent called an isocyanate to create the materials that would become polyurethane. Bayer received his doctorate in 1924 from the University of Frankfurt and entered industry with IG Farben, the German dyestuff conglomerate. Because the Bayer Corporation was one of the companies involved in the IG Farben group, it is often assumed that Otto was related to the Bayer family that founded the company. However, there is no such familial relationship.

By 1931 Otto found himself at the helm of the Central Research laboratory in Leverkusen, where he began investigating the chemistry of reactions involving the remarkably reactive isocyanate functional group. Over a period of several years, he succeeded in developing a reaction between hexamethylene diamine, one of the monomers used to make nylon 66, and hexamethylene diisocyanate, to form the first of a family of materials that today are collectively called polyurethanes. This technology was patented in 1937.

A year later, Heinrich Reinke, a member of Bayer’s team, developed an alternate route to polyurethane synthesis that is more typical of the current technology. Reinke reacted butylene glycol, the same material used to make PBT polyester, with another diisocyanate. Both of these diisocyanates were aliphatic in structure and the molecular weight of the resulting materials was relatively low. But this reaction was the beginning of the creation of what is arguably the most versatile chemistry in polymers.

The first product of this research was polyurethane foam, and there are pictures of a smiling Bayer looking at the fruits of his efforts, a large mass of foamed material. The early foams were created by accident. Moisture reacts readily with isocyanates, forming a substance called carbamic acid, which is unstable and rapidly decomposes into an amine and carbon dioxide. The carbon dioxide acted as a foaming agent and therefore it is not surprising that polyurethane was first introduced commercially in the form of foams. Free carboxylic acid groups in the polyesters that were reacted with the diisocyanates also contributed to carbon dioxide production.

Early PUR foams were created by accident.

But it did not stop there. The foams could be rigid or soft depending upon the level of volatile gas generated during production. Over time, this was controlled better by reducing moisture levels and intentionally introducing other gases as the foaming agent. The first foams were of the soft variety, but by the mid-1950s rigid foams were commercialized and found immediate use in building and construction.

Boosting the Molecular Weight

It was also discovered that polyurethanes made excellent adhesives and sealants as well as coatings for materials like hardwood floors. For all of these purposes, products could be fabricated without being too concerned about molecular weight. For fibers, and especially for molded elastomeric parts, the considerations of molecular weight became more important. While Bayer is credited with the discovery of polyurethane chemistry, his materials were based largely on aliphatic reactants and would be properly classified as polyureas.

Research on boosting the molecular weight of polyurethane polymers started as early as 1941 at DuPont. This work was done by William Hanford and Donald Holmes, who received a patent on the process of making polyurethanes in 1942. Hanford and Holmes discovered the chemistry of including long-chain diols, called polyols, into the polyurethane chemistry. This increased chain length and improved control over mechanical properties. Longer chain polyols produced softer materials since these groups represented the soft segments of the structure while shorter chain polyols created harder materials. Today, polyurethanes can be produced with hardnesses that range from 55 to 60 on the Shore A scale up to 75 on the Shore D scale. Initially, the polyols were based on polyester chemistry.

As is so often the case, world conflict both catalyzed development and produced immediate applications. The elastomeric character of polyurethane led to its use as a substitute for natural rubber, which was often difficult to obtain from areas of the world steeped in throes of World War II. Development continued after the war. By 1952, high-molecular-weight polyurethanes became available based on a reaction between polyester-based polyols and an aromatic diisocyanate, toluene diisocyanate (TDI). By 1957, rigid foam was being produced for insulation by the French glass manufacturer Saint-Gobain.

Versatility of polyurethanes: (2) Rigid foam pipe insulation. (Photo: Covestro)

This same era also saw the development of polyurethane foam for surfboards. Also at this time, polyether-based polyols were introduced as an alternative to polyesters. Polyethers offered improved resistance to hydrolysis while polyesters tended to have better mechanical properties. Both of these options exist today, along with polycaprolactones and even polycarbonate. The first polyether, polytetramethylene ether glycol (PTMG), was introduced by DuPont in 1956 and also became a key component in the chemistry of copolyester-based thermoplastic elastomers, trade-named Hytrel. In the following year, Dow and BASF developed chemistries based on PTMG reacted with methylene diisocyanate (MDI) and ethylene diamine. DuPont created a fiber from this chemistry that became known as Lycra Spandex.

By 1962, materials exploiting a wide variety of these chemistries were being produced that could be molded into standalone products. These could be thermoplastic or thermosetting depending upon the chemistry of the constituents. A singular benefit of these materials was outstanding abrasion resistance combined with a high degree of ductility. The crosslinked systems tended to outperform the thermoplastic variety, with better wear resistance and lower compression set.

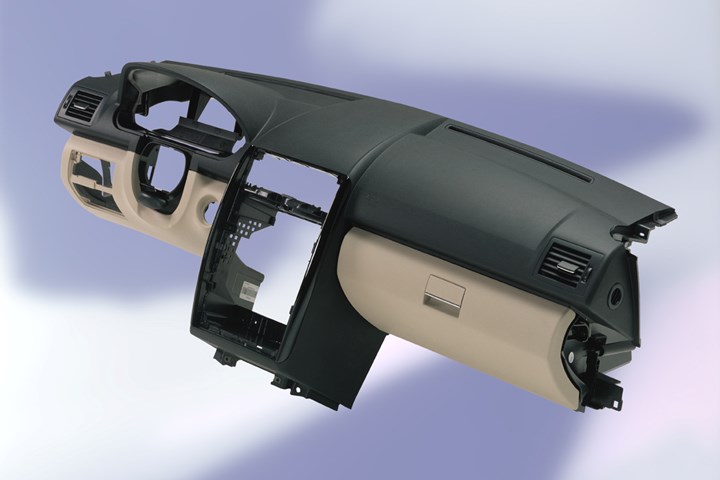

Versatility of polyurethanes: (3) RIM semirigid elastomer. (Photo: Thieme Corp.)

Introduction of RIM

In 1967, Bayer exhibited a complete plastic car body in Düsseldorf at the K Show. Many of the panels were produced from a new process called reaction injection molding (RIM). This technology involved injecting the liquid constituents needed to create the polyurethane polymer into the mold and polymerizing the material in the mold at the same time the part was being formed. This was more of a proof-of-concept demonstration, but by 1983 it became a commercial reality when the Pontiac Fiero was introduced with an all-plastic body made of RIM panels. The polyurethane material had a limited modulus, and later enhancements involved placing glass mats into the mold that acted as reinforcing agents to stiffen the material. This became known as structural RIM (SRIM).

The combination of abrasion resistance and good low-temperature impact also made polyurethanes ideal for wheels on items like roller skates and skateboards. These were introduced in 1973. In the late 1970s I worked with a company that made screw conveyors where a metal chain runs over the gears. The gears are typically metal and the company wanted a plastic gear.

We started with an acetal homopolymer due to its reputation for wear resistance with good lubricity. The loss of material through wear was substantial. We then molded some gears from a Shore 45D polyurethane and they exhibited no significant wear after tests that ran more than 1000 hr. It was a real education in the properties of polyurethanes.

Even a cursory investigation into polyurethanes shows that the material family has unparalleled versatility, not only in terms of the forms the material can take but in the different ways in which it can be processed. This arises directly from the unique chemistry of this material family, which will be the topic of our next installment.

About the Author: Michael Sepe is an independent materials and processing consultant based in Sedona, Ariz., with clients throughout North America, Europe, and Asia. He has more than 45 years of experience in the plastics industry and assists clients with material selection, designing for manufacturability, process optimization, troubleshooting and failure analysis. Contact: (928) 203-0408 • mike@thematerialanalyst.com

Related Content

Tracing the History of Polymeric Materials -- Part 30: Polyurethane

In the world of polymers, polyurethane chemistry is probably the most versatile. This a resulted in a wide range of products made from these materials and given the industry the flexibility to respond to the progressive march of regulatory concerns.

Read MoreGEON Performance Solutions Buys PolymaxTPE

Combined company aims to be global leader in thermoplastic elastomers.

Read MoreFoster Adds Specialty TPU and TPU Alloy Products to its Arsenal of Healthcare Materials

AdvanSource Biomaterials’ specialty TPU materials are used in application segments such as cardiology, orthopedics, drug delivery, endoscopy, wound care, urology, and neurology.

Read MoreTPEs Meets NSF 51 Regulation for Commercial Food Equipment

Kraiburg’s new TPE series aimed at seals/gaskets, valves, flexible connectors, food contact hoses, and more.

Read MoreRead Next

Tracing the History of Polymeric Materials, Part 26: High-Performance Thermoplastics

The majority of the polymers that today we rely on for outstanding performance — such as polysulfone, polyethersulfone, polyphenylsulfone and PPS — were introduced in the period between 1965 and 1985. Here’s how they entered your toolbox of engineering of materials.

Read MoreTracing the History of Polymeric Materials, Part 25: Silicones

The long road to the development of silicone resulted in a chemistry that is remarkably versatile.

Read MoreTracing the History of Polymeric Materials, Part 27: Liquid-Crystal Polymers

Liquid-crystal polymers debuted in the mid-1980s, but the history of the chemistry associated with this class of materials actually starts a century earlier.

Read More

.jpg;width=70;height=70;mode=crop)