Use Pressure Control to Minimize Process Variations in Single-Screw Extrusion

You can improve process stability in extrusion by using pressure-control feedback. The stability of the process is based on the pressure variation in the adapter after the extruder. Trials on a variety of polymers revealed how effective this approach can be.

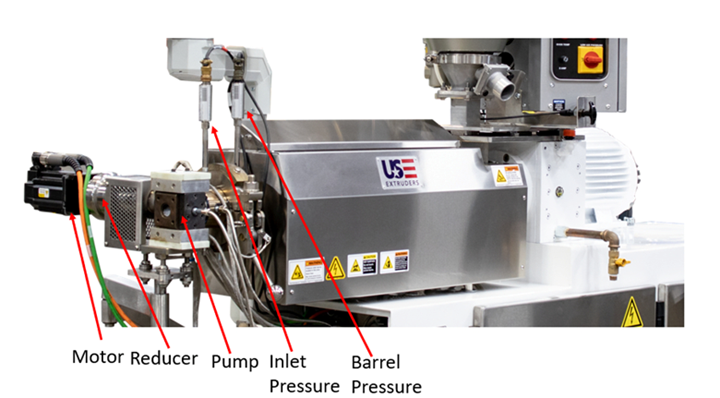

Improving process stability is important to maintaining tight tolerances in the final product. Commonly, if the extruder cannot deliver melt at a tight enough tolerance, a melt pump would be added to the system. A melt pump is a constant-volume device with two intermeshing gears driven by a motor. The melt flows into the inlet, enters into a tooth of the gear, goes around the outside of the gear, and gets forced out of the pump when the teeth mesh. The inlet pressure is controlled by making small changes to the extruder screw speed (Fig. 1).

FIG 1 Typical extruder and melt-pump setup. (Photo: US Extruders)

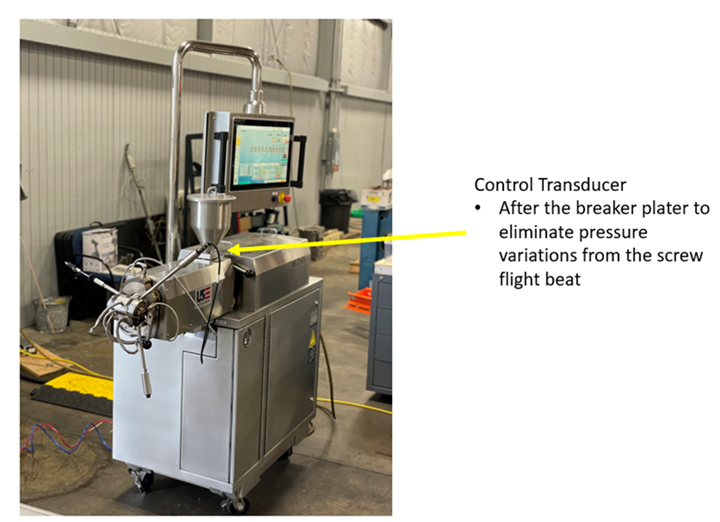

In the case of pressure control, the controller will make the same adjustments controlling the pressure in a downstream adapter (Fig. 2). A pressure transducer downstream of the extruder is used for control of pressure. The controller, either discrete or PLC-based, will adjust the extruder screw speed to maintain the pressure by making minimal speed changes at a very high frequency. Since these changes are less than 2 rpm, there is very little influence on the melt temperature of the polymer. In order for autotuning of the PID parameters, a step change to the screw speed is performed to calculate the reaction of the polymer to the change in speed. This cannot be done with a melt pump.

FIG 2 Pressure-control setup. (Photo: US Extruders)

Process stability is defined by the pressure variation measured in the adapter after the extruder. At a fixed restriction, a change in pressure is related to a change in output rate (assuming a fixed melt temperature). This can be shown via fundamental equations of pressure drop versus output rate. Taking these equations and using a power-law equation for the viscosity, the following equations can be developed:

Q∝ (P/η)1/n

ΔQ = 1/n (ΔP)

Were Q is the output rate, P is the pressure drop, and n is the power-law constant.

Therefore, if you minimize the ∆P it will minimize the change in output, resulting in improved process stability. With the current pressure controllers and the rapid response of modern drives and motors, the measured pressure variation can be minimized.

The Trials

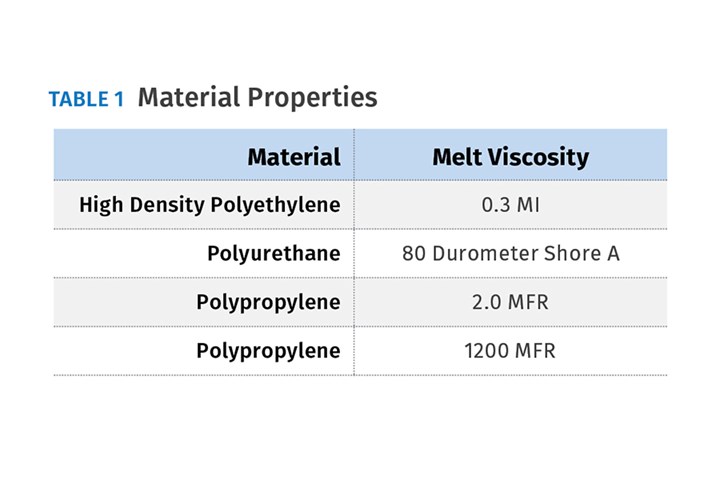

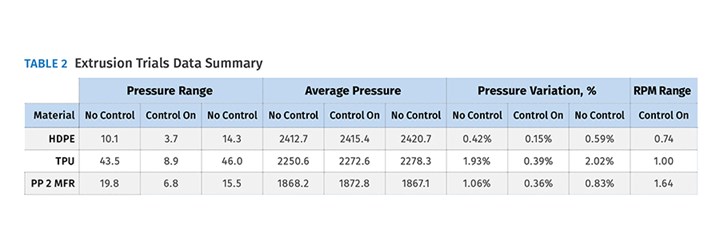

Trials were conducted on a 0.75-in., 24:1 L/D extruder with a 3:1 compression-ratio metering screw to examine the improvement in process stability. Four different materials were evaluated (Table 1). The extruder setup is shown in Fig. 2.

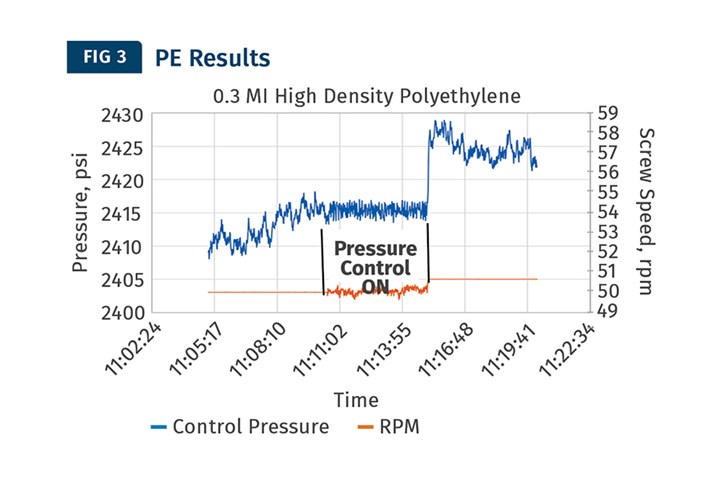

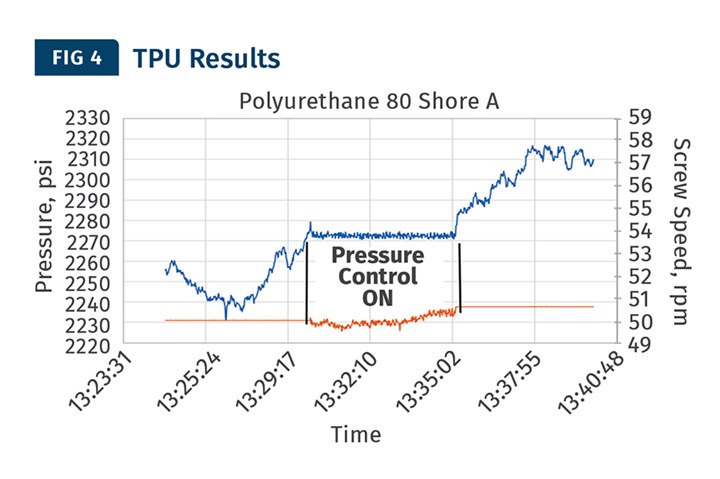

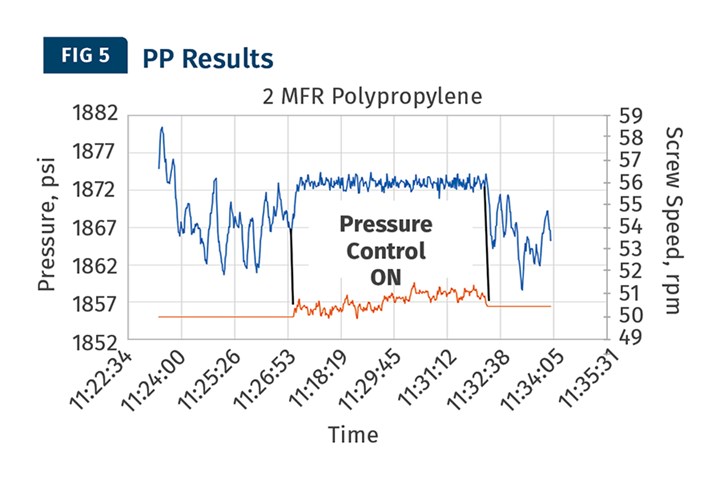

The trials were all conducted at a fixed screw speed of 50 rpm and fixed temperature profile of 350° F. For each material it was run until it reached steady state, at which point the pressure controller was autotuned for each resin. Once the PID parameters were calculated, the material was run for 5 min with no pressure control, then pressure control was turned on for 5 min, finally pressure control was turned off and ran for another 5 min.

For each of these steps the pressure, pressure variation, and screw speed were measured. This data is shown in Figs. 3-5. The autotune routine could not develop PID parameters for the 1200 MFR PP material. This is due to the very low viscosity of this material, and slight changes in the screw speed did not respond effectively.

Blue curve shows reduced pressure variation with pressure control on. Screw-speed curve (orange) shows minimal changes in rpm to achieve the improved stability with all three materials tested. (Data: US Extruders)

The Outcome

The results from the three trials are presented in Table 2. The data show there can be a 20-40% reduction in pressure variation. The reduction is very dependent on the material and viscosity characteristics. It was revealed that very low viscosity materials may not benefit from this technology. The controllers are commercially available and allow for autotuning, whereas determining the PID for a melt pump must be tuned manually. Pressure control is a good option that removes the need for a melt pump.

Eliminating the melt pump offers benefits that include removing the motor, drive, pump, and inlet adapter. The result is less maintenance, shorter adapters, and less residence time. Further work needs to be done on larger-diameter extruders as there is a bigger influence on melt temperature versus screw speed due to the higher shear rates at a given screw speed.

EDITOR’S NOTE: This article was based on a presentation Slusarz gave at Plastics Technology’s Extrusion 2021 Conference. He is presenting a paper on this topic at TAPPI’s International Flexible Packaging and Extrusion Division's 2022 FlexPack PLACE Conference, Apr. 10-13 in Austin, Tex.

ABOUT THE AUTHOR: Kevin Slusarz has been in the plastics industry for over 30 years, primarily in designing single screws and dies. He has both a Bachelor of Engineering and a Masters of Chemical Engineering from Stevens Institute of Technology. He is currently on the board of directors for the Extrusion Division of SPE. Over his career he has worked for Egan, Davis-Standard and American Kuhne and is one of the cofounders of US Extruders, Inc. where he is responsible for screw design and process support. Contact: 401-584-4726; kslusarz@us-extruders.com; us-extruders.com.

Related Content

How to Estimate and Control Head Pressure

You rightfully worry about melt temperature, but don’t overlook head pressure, because the two are closely linked and will influence line performance.

Read MoreFormulating LLDPE/LDPE Blends For Abuse–Resistant Blown Film

A new study shows how the type and amount of LDPE in blends with LLDPE affect the processing and strength/toughness properties of blown film. Data are shown for both LDPE-rich and LLDPE-rich blends.

Read MoreAvoid Four Common Traps In Granulation

Today, more than ever, granulation is an important step in the total production process. Our expert explains a few of the many common traps to avoid when thinking about granulators

Read MoreHow Much L/D Do You Really Need?

Just like selecting the extruder size and drive combination, the L/D should be carefully evaluated.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read More

.png;maxWidth=300;quality=90)